Feed production as a profitable business idea. How to make money on the production of compound feed Business of growing and producing compound feed

The production of compound feed as a business will be a profitable enterprise only if everything is organized correctly. The agricultural industry today presents many prospects. The constant growth of farms makes farm maintenance services in demand. People who keep a large number of livestock always need nutritious and balanced animal feed. Therefore, feed production is one of the most successful business formats.

The main advantage of this area is its simplicity and ease of marketing. Agricultural farms often experience a shortage of feed, so even a novice entrepreneur has every chance to gain a foothold in this industry. In this review, we will look at what feed production is like as a business and the features of this area. In addition, we will draw up a rough plan.

Production Features

Despite the fact that agricultural feed is a highly sought-after product today, a newcomer to this business will definitely have to take into account the requirements of customers. Experienced farmers will never buy low quality feed. It is vital that the product you produce is balanced. It must contain all the microelements and vitamins necessary for the animal’s body. Only in this case will the livestock be healthy. To do this, it is not at all necessary to adhere to ready-made recipes. You may well be able to create new varieties of food. This variety will attract new customers.

Raw materials

What is feed production as a business? The plan of this enterprise must necessarily include such an important item as raw materials. Typically, entrepreneurs use legumes and grains for production. Also, in some cases, hybrid varieties can be used. The production of compound feed will provide regular profits only if you begin to produce high-quality products. The farmer can easily determine how balanced the nutrition is. They very often refuse cheap products that are poor in composition in favor of more expensive ones that are high in natural protein, microelements, vitamins and other useful microelements. If an entrepreneur can create a truly good food recipe, his products will always be in demand.

Profitability

How profitable will it be to produce compound feed at home? Of course, enterprises with large production of raw materials show the highest profits. However, to open such a business, you will need quite large investments - starting from 2 million rubles. But small entrepreneurs also have the right to exist. Of course, their level of profitability will be much more modest.

Before starting feed production as a business, you need to think about distribution channels for finished products. Typically, entrepreneurs in this area work with consumers such as nurseries, farms, zoos and individuals. To prevent products from sitting in warehouses, most of them should be sold to wholesale customers. To do this, it is recommended to conclude supply agreements at the initial stage of doing business. You can also try offering your services to government organizations. However, the most promising buyers are private farms. Firstly, they are interested in buying a quality product, and secondly, they are willing to pay a high price for the product.

Types of feed

What are they? How to start a feed production business? Let us determine that granulated raw materials can be intended for preparing feed for various animals and birds. Typically, grains are included as the main ingredient. In order for the composition to promote the growth of livestock, it is necessary to additionally add nutritious protein supplements to it. In addition, vitamins E, A and D must be included. The food also includes microelements and amino acids. For individuals of different ages, the composition of raw materials may vary. Basically, the concentration of biologically active substances will change.

Relationship between composition and quality indicators

Many people today are interested in a business plan for the production of animal feed. The requirements for this product are mainly based on providing animals with all the necessary nutrients.

The following indicators will depend on the composition of the feed:

- rate of growth and development of livestock;

- physical activity;

- rapid gain of muscle and fat mass;

- wool growth rate;

- egg production;

- volume of milk received.

A balanced and nutritious diet is especially necessary for birds and animals kept in closed enclosures and pens. The fact is that such individuals do not have enough free space to maintain the required level of physical activity. Therefore, their development and growth must be stimulated with food.

Who is it suitable for?

Who can set up the production of compound feed? The business idea is perfect for owners of their own farms. They can not only save a significant amount on the production of feed, but also independently control its composition, selecting only the highest quality ingredients that are optimally suitable for the birds and animals kept.

Many farmers prefer to buy feed from large suppliers. Therefore, a business plan for the production of animal feed can be especially useful for beginning entrepreneurs.

Product range

Large farms also choose large producers because of the wide variety of products they produce. After all, different animals require different sets of ingredients and nutrients. Many manufacturers also create special product lines for young animals, pregnant and lactating animals, and adults. The first category is characterized by a high content of nutrients.

Products are usually classified according to their nutritional value. contain a large number of different nutrients. Balanced ones are additionally enriched with microelements and vitamins that are beneficial for animals. For daily use on farms, complete raw materials are usually used.

If you consider the production of compound feed as a business, then you can specialize in either one type of feed or several at once.

Release form

At the initial stage, you will also need to decide in what form you will begin to produce finished products.

Here are the following options:

- Granulated food: comes in the form of elongated or rounded lumps.

- Briquetted: this variety is characterized by increased density of raw materials. Produced in the form of rectangular and square tiles.

The demand for a particular type of product largely depends on who the food is made for. Large livestock farms prefer to buy products in briquettes. For poultry and pigs, bulk and granulated feed of medium grinding can be used. But how to determine which form of release will be more in demand? This question is asked by many of those who have decided to plunge into feed production as a business. Reviews from professionals will help you choose the right format. Experts will also advise how to select components and develop a composition. Please note that after creating the recipe, it will be necessary to carry out the necessary laboratory tests and studies. The results of such an examination will be proof of the high nutritional quality and usefulness of your products.

Business plan

What is he? How to draw up a business plan for an individual entrepreneur? Feed production is an extremely specific type of activity that requires taking into account many factors. If necessary, you can still use the help of specialists here. Entrepreneurs with experience in the production of mixed feed will help you correctly assess the real cost of the finished product, determine the amount of necessary costs and the approximate demand for the product from farms. If a novice entrepreneur is extremely serious and plans to open a large production facility with various product lines, then it is better to work in several directions at once. The wider the range of products, the more customers the entrepreneur will be able to attract. The end result will be good profit for the entire enterprise.

What you need to get started

What is needed to establish feed production as a business? The first issue to take care of is the purchase of raw materials. As a rule, entrepreneurs in this area use meal and cake. High-quality straw and grain can also be used.

Additional components are:

- meat and bone meal;

- syrup;

- salt;

- vitamin and mineral supplements;

- protein premixes.

Production technologies

What do you need to know about this? The quality of the finished feed also depends on the production technologies used. For example, during the production of bird feed, a mandatory procedure is to exfoliate the grains. This is not required for other types of raw materials.

Most entrepreneurs today prefer to produce granulated feed. This process consists of several stages. First, the raw materials are crushed using special equipment. The size of the resulting particles varies from 10 to 40 mm. After this, the raw materials obtained in the first stage are placed in the dispenser. There it is mixed with various additives. The quality of the finished product will depend on the accuracy of dosing of all ingredients. To mix all the components of the feed and turn them into a homogeneous mass, special equipment is used. After this, granules are made using a press. Then the finished chilled products are packaged in bags.

When producing bulk feed, the first technological steps will be exactly the same. The finished product is packaged immediately after mixing.

Premises and equipment

What is needed to establish feed production? A business idea requires significant costs to be implemented. If a novice entrepreneur decides to open a full-fledged automated production, he will need a fairly spacious room with professional equipment. It is also worth taking care in advance of a place to store raw materials and finished products. There are no special requirements for the warehouse premises. The main thing is that it is dry there.

All equipment in the production workshop must be installed in accordance with regulations. Therefore, it is best to purchase specialized equipment from large suppliers who also debug and install it. The quality of the finished product will ultimately depend on the quality of the technologies used. It is worth considering that the production of granulated feed is a rather expensive process. The purchase of one production line of sufficient capacity will cost you 1.5 million rubles.

Today, individual entrepreneurship in the village is an important part of the development of the agricultural industry as a whole. More and more people are starting to raise cows, pigs, rabbits and poultry, which, in turn, requires compliance with certain technologies. If we talk about feeding, then meat growth is ensured through the use of compound feed - a mixture of various grains and other ingredients, which, due to its structure and composition, ensures good digestibility and is more nutritious than conventional feed. The demand for such products is consistently high. However, many rural entrepreneurs note that the quality of factory-made feed is more a matter of luck than a 100% guarantee. Many of them would prefer to buy such products from trusted people who produce food at home. Investments in such home production are relatively low, but the prospects for development are enormous. Perhaps, over time, you will be able to develop your small enterprise into a full-fledged production line.

Required Ingredients

The first thing an entrepreneur should remember is the feed recipe. She is of utmost importance in this business. There are more than a hundred types of different raw materials that can be used to produce feed for animals and poultry. The basis of such feeds is fiber (due to its unique structure, it easily swells and absorbs liquids, increasing in volume in the body and improving digestibility), i.e. cereals. The percentage of its content will be as follows: 30-35% for rabbits, 15-20% for pigs, 20-25% for cows, 10-15% for chickens. However, all proportions, list and quantities of ingredients will depend on the specific recipe.

Most often used for the production of animal feed:

- Cereals: barley, corn, wheat, oats, beans;

- Hay, straw and cake;

- Fish, herbal, meat and bone meal;

- Molasses, hydrol;

- Chemical additives: various vitamins, antibiotics, microelements;

- Salt, honey, water, sunflower oil.

Below you can also see the lists of the main ingredients of feed for rabbits, pigs, chickens, and cows.

- Barley - 25%;

- Wheat bran - 5%;

- Corn - 15%;

- Herbal flour - 35%;

- Sunflower meal - 20%.

- Corn - 20%;

- Wheat - 10%;

- Salt - 0.2%;

- Barley - 20%;

- Sunflower meal - 30%.

5.5 kilograms of such feed yield 1 kilogram of meat (if we are talking about regular feed, you will need 7 kilograms).

- Wheat - 25%;

- Corn - 17%;

- Herbal flour - 15%;

- Shell rock - 3%;

- Barley - 25%;

- Sunflower meal - 15%.

- Barley - 20%;

- Wheat bran - 15%;

- Herbal flour - 25%;

- Corn - 15%;

- Sunflower meal - 25%;

- Salt - 0.5%.

These recipes are not universal, but they provide an understanding of the composition and proportions of various ingredients in the feed.

Necessary equipment

To produce feed at home you will need the following equipment:

- Scales. Compound feed for poultry, cows, rabbits, etc. prepared according to different recipes. In order to carefully observe all the given proportions, you need a good scale.

- Grain crusher. Such devices are necessary for high-quality grain grinding. They are very compact and inexpensive - for example, a good crusher for home use can be purchased for 4-5 thousand rubles.

- Grain mixer. Mixers, unlike grain, take up a lot of space. They can be vertical or horizontal. Such equipment costs a lot, about 50 thousand rubles or more, depending on the characteristics. However, many people involved in agriculture do without this device, grinding grain in a mixer and then stirring it manually. However, for business this method is too energy-consuming.

- Extruder. An extruder is equipment that is necessary to significantly increase the nutritional value and digestibility of feed. The cost of such devices may vary, but the most inexpensive ones can be purchased for 40-45 thousand rubles. Already crushed grain and other ingredients are placed there, after which they are processed at a temperature of 170-200 C. This not only increases digestibility and nutritional value, but also improves the taste of the mixture, kills bacteria and allows rational use of feed. Not all people involved in agriculture use an extruder to prepare nutritional mixtures, but if you want to make this food for sale, it is still worth purchasing an extruder.

- Granulator (from 50 thousand rubles). Compound feed may vary in release form. It can be loose, briquetted or granular. It is the latter type that is the most in demand, which is why an entrepreneur needs to purchase a granulator. Its main function is to give the mixture the shape of identical particles, that is, granules. This increases shelf life, simplifies the packaging process, allows you to easily feed animals and birds with what they usually refuse to eat, increases nutritional value, and simplifies the process of transporting the finished product.

*There are quite a few videos and even drawings of homemade granulators and mixers on the Internet. If you know you can handle this kind of work, you can significantly reduce your startup investment and make the equipment yourself.

Step-by-step feed production technology

The feed manufacturing technology will depend on the chosen molding method, the presence or absence of certain equipment, and the selected recipe. Below are all the basic steps using different instruments. This should help you understand the sequence and specifics of the process of making compound feed at home.

Measure out all the ingredients for the selected feed recipe using a scale.

Pass them through a grain crusher. Some entrepreneurs do this in advance, grinding wheat, oats, peas, corn, etc. and storing them in separate barrels. This saves time and reduces the number of tasks during the production of the finished mixture. So instead of taking the first two steps, they take one by simply measuring out the ingredients.

Pour ingredients into mixer. This should be done one at a time. If the feed contains liquids, for example, sunflower oil, they should be poured into the machine last. If you are producing loose non-extruded feed, this is where its preparation ends. The mixture is weighed and packaged. As mentioned earlier, some people who make their own feed mix the mixture by hand, without using a mixer.

If you have an extruder, you should use it immediately after mixing the ingredients. There the mixture is subjected to heat treatment. At the exit, it becomes like “sausages”, which can be easily returned to a crumbly state by simply kneading them with your hands or any suitable object in a deep container.

The feed is cooled and packed into bags.

Sales areas

Of course, such a business is difficult to imagine in an urban format. An entrepreneur can purchase equipment, place it, for example, in a garage, and begin production. However, the goods need to be sold in the village and, most likely, at retail, since such a scale of activity simply will not allow the production of goods in batches that can be sold to farms.

If an entrepreneur lives and works in a village, he can sell feed to his fellow villagers. If your friends buy a bag of mixture and notice a significant weight gain in livestock and poultry, word of mouth will work instantly, providing you with a large number of customers. Hypothetically, the product can also be sold to farms, nurseries, nature reserves and even zoos, but this will only become a real option when your business grows to a full-fledged production line.

Conclusion

Producing feed at home is a truly win-win idea for those who live in rural areas, run their own farms and are looking for an additional, stable source of income. Despite the fact that the equipment is not so cheap, once you invest money in it, you will have the opportunity to produce completely natural, safe feed for both your own livestock and for sale.

Today in Russia agriculture is developing rapidly - this is caused both by sanctions imposed by the government and by a general shortage of high-quality and inexpensive products in stores. I would especially like to note the increase in the number of poultry and pig farms - as of 2018, Russia has fully provided itself with this meat and has even begun to export it to other countries. To raise poultry, pigs and fish, you need compound feed that is highly efficient and has a long service life. It is precisely in conditions of rapid growth in the number of farms that it is recommended to considerThis is a profitable and interesting business with quite profitable prospects.

Introduction

Compound feed is a product that consists of high-quality raw materials combined in the required proportions. Its beauty is that the composition of the feed is balanced, that is, by eating it, the animal receives everything it needs for normal development. A high-quality product includes a herbaceous base, a set of grains and legumes, meat and bone meal and various additives with micro-macroelements and vitamins.There are several types of feed, but we will talk about this later. We only note that in order to increase sales, you should produce a variety of varieties to cover all the needs of the farm or population: for poultry, for pigs, for cattle, etc. There are also specialized varieties on sale, for example, for laying hens, for chickens over 1 month old, etc.

Different types of feed

How to register

In order to open your own production, you need to decide how exactly you want to register. There are two options:

- Individual entrepreneurship.

- Limited Liability Company.

Attention:An LLC is preferable for an enterprise because it opens up wide opportunities for the owner. In an LLC, you can divide shares, hire a general director, and work with large companies that prefer not to get involved with individual entrepreneurs.

In order to register an LLC, you will need to prepare the following set of documents:

- LLC Charter, which is a standard document.

- Minutes of the meeting of organizers. If there is only one founder, then a decision of one person is necessary.

- An application to the tax authority in form P11001, which is written after the signing of the establishment agreement.

You will also need to pay a fee of 4 thousand rubles. Please note that all of the above documents are standard, that is, you can simply download the charter from the Internet and adjust it to suit your realities. Then, with these documents and the original receipt, you go to the tax office and write an application for registration. Within 5 days they give you a response about successful registration and give you a copy of the charter, OGRN, INN and an extract from the Unified State Register of Legal Entities.

Selecting a room

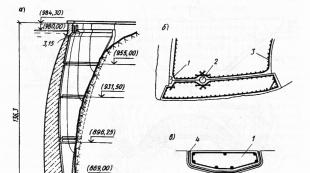

We will not consider garage production, since it will not produce significant volumes. Let's figure out what kind of room will be needed forPractice shows that for normal functioning a workshop with an area of at least 300 m2 is needed, with at least 80 m2 being used for storing raw materials, 80 m2 for storing finished goods, approximately 100 m2 is needed to accommodate a production line and another 40 m2 will be needed for utility rooms . Please note that this is the bare minimum. A normal workshop looks like this:

- The production zone, which includes a zone for crushing incoming raw materials, a zone for processing ground raw materials, an extrusion zone, a granulation zone, and a mixing zone.

- A full-fledged workshop for cleaning incoming raw materials.

- Area for processing grass and straw into flour.

- Area for processing oilseeds.

- Two fully equipped warehouses for raw materials and finished products.

Note that you do not need to choose a room in the center - workshops on the outskirts or even outside the city are suitable. The main thing is that they have a convenient transport interchange and parking space for trucks that will bring raw materials and deliver finished products. The height of the room must be at least 4 meters, so classic residential premises will not be suitable.

The production workshop must be spacious enough

Equipment selection

Let's consider whatmust be purchased to get started. You will need to buy:

- Crusher for grains and legumes.

- Specialized chopper for grass and straw.

- An extruder that will carry out various thermal procedures.

- Conveyor belt for supplying raw materials and discharging finished products.

- Granulator to give the required shape.

You will also need to buy a device for packaging into bags. Note that all this can be purchased separately or as a finished line. It is better to choose a ready-made one, since you will receive a fully debugged and balanced system that can work in three shifts and at the same time have an optimal layout that reduces production time.

How to sell

In order to increase confidence in your products and increase the number of customers, be sure to go through the certification procedure. This is not difficult to do - immediately after the release of the first batch of goods, you submit samples to the laboratory and receive the necessary documents confirming that the product meets the specified characteristics.

Attention:certification is carried out over 30 days, but, as a rule, takes no more than two weeks. The quality certificate significantly increases the number of clients.

In parallel with certification, think about where and how much you will deliver the products. There is no need to look for retail clients or think about opening your own store. It will be more profitable, easier and cheaper for you to hand over finished goods in bulk to large customers than to sell them to small retailers.

Before launching production, think about which products will be in greatest demand. For example, if there is a poultry farm nearby, then it will probably need bird feed. If fish are bred nearby, then you need appropriate food, etc. Note thatis the same, but the recipe may be different, so you need to study it carefully and understand what it should be for different animals. There are several types of feed:

- Complete, which can be used as daily food.

- Concentrates containing a high percentage of protein.

- Additional, which are given with the main food. They contain essential vitamins and minerals.

Feed can also be divided according to form:

- Granulated, which are produced in the form of cylinders 2-5 cm long.

- Briquetted, produced in tiles. When consumed, the briquette is broken and given for food.

- Loose, produced in the form of a mixture (similar to medium-ground flour).

Granular feed is the most common

We study demand

Before you launch production line for production, we recommend that you study the local market to understand how quickly you can recoup the costs and what exactly will be popular.

Attention:According to statistics, in Russia 70% of feed is consumed by livestock companies and only 30% by the population. Therefore, it is better to focus on factories.

We also note how the division is carried out by type of animal:

- Poultry farms consume 60% of sold feed.

- Pig farms consume almost 25% of the total volume.

- Cattle consume 13% of goods.

- Fish farms consume 2%.

The percentages may fluctuate slightly from year to year, but as of 2018, this is where they are.

We count the costs

So, above we looked at the main key points of the business. Now let's figure out how much you need to invest to start an enterprise. The costs are as follows:

- Company registration - 10,000 rub.

- Rent of premises and utilities - 1,000,000 rubles. in year.

- Purchase of an automatic line - 1,500,000 rubles.

- Purchase of raw materials for work - 500,000 rubles.

- Other costs for certification - 50,000 rubles.

In total, 3,060,000 rubles must be spent on mandatory expenses. Next, let's look at monthly expenses:

- Salary for 4 workers - 100,000.

- Taxes - 50,000.

- Other expenses - 50,000 rubles.

- Purchase of raw materials for a month of work - 500,000 rubles.

T But every month the expenses will be 700 thousand rubles.

Classic production equipment

We count income

Next, let's look at the most enjoyable part of the article: how much income the company will receive and how quickly it will pay for itself. Of course, this is an approximate feed production business plan — it all depends heavily on how you organize the process, which line you choose, how you will sell, etc. But let’s give average figures.

So, a modern line is capable of producing 1 ton of finished product per hour. Of course, you are unlikely to be able to achieve such a load in the first couple of months, but in the future, when debugging the process, this is quite possible. The profitability in this type of business is 20% and this is a very realistic figure. In this example, we will take the average line load at 70%, that is, 700 kg of product per hour. In one shift, your line will produce 700 * 7 = 4.9 tons of products (it will take an hour to start - complete work). In a month, the enterprise will produce 4.9*23=112 tons of finished products.

The average cost of a ton in Russia at wholesale is 9 thousand rubles, that is, in a month you will receive revenue in the amount of 1,000,000 rubles with a net income of 300,000 rubles. Over the course of a year, the enterprise will bring you 3.6 million rubles, fully recouping the expenses incurred.

Attention:We looked at a situation where an enterprise operates at 70% of its capacity. This is a fairly correct calculation, since with the right approach you will reach a similar volume in 3–4 months.

Then you will be able to constantly increase production, since there are virtually no restrictions. In case of increased demand, you can launch manufacturing goods in the second and even third shift, thanks to which you will pay for yourself much faster (when working in 3 shifts, the costs pay off in six months). The main thing is to maintain the required quality of the product, because if the animals do not eat it, get sick or grow slowly, then farms will refuse to purchase and you will lose business. There is no need to skimp on quality - make a good product, and you will never end up with customers.

In contact with

Compound feed is a mixture that is used to feed farm animals and birds. Thanks to the use of high-quality feed, animals receive adequate nutrition. There can be many recipes for preparation, and each type, as a rule, contains the same types of raw materials, which are contained in different proportions and are accompanied by various additives.

Breeding poultry and livestock is a very important area in every country, and feed production is usually carried out by highly specialized companies. If you have experience and skills in this field, then this type of business will be an excellent option. Typically, organizations involved in the field of agriculture give preference to imported feed, but due to the rise in price of the latter, they have increasingly begun to purchase domestic feed, which is not inferior in quality.

The production of compound feed has its advantages and disadvantages.

The advantages include the following:

- A product in demand, since agriculture does not stop in its development and constantly needs to purchase quality feed.

- Ease of doing business. To open this business you will need a minimum of knowledge and skills.

- Small capital investments, their optimal ratio to profit, which ensures a quick return on costs.

- Despite the high level of competition, even a start-up enterprise, thanks to well-designed advertising, can find its customer base.

- Possibility of further development. Despite the nuances, the business is promising, and a small enterprise can subsequently grow into a larger one and occupy a large part of the market.

Despite the advantages, the area also has a number of disadvantages:

- Competition.

- Difficulties in finding quality raw materials.

So, despite a number of disadvantages of the project, its opening will be very promising and will bring the owner significant amounts of profit and the opportunity for further development.

Types of feed and purposes of their use

There are several types of feed that depend on nutritional value. The optimal composition depends on the recommendations of veterinarians, as well as on the latest research data, which reflect the influence of certain substances on the taste characteristics of food. Regarding production, it can be noted that any product must be saturated with the entire spectrum of essential nutrients, and their proportions must be strict.

Classification

Compound feed is divided according to the form of the product, which can be loose, granular and briquette. Classification is also carried out based on the types of animals for which it is intended. For example, one type of feed will be used for animals intended for breeding, and another type will be used for animals for slaughter. The type also depends on their age and breed.

Compound feed is divided according to the form of the product, which can be loose, granular and briquette. Classification is also carried out based on the types of animals for which it is intended. For example, one type of feed will be used for animals intended for breeding, and another type will be used for animals for slaughter. The type also depends on their age and breed.

The main question that manufacturing companies will face is related to the quality of their products. The fact is that animals that are bred and raised at home need to consume high-quality food, because their health and life expectancy largely depend on this.

The second problem is pricing. The retail price of good quality food will not be low. But due to the crisis, many farmers adhere primarily to the criterion of price rather than quality.

Domestic manufacturers sell their products through wholesale organizations, as well as through direct sales. Ideally, you should agree that certain companies will regularly make wholesale purchases from you. This way it will be possible to ensure stable sales of products.

Production premises and equipment

- Production of placer and granules. The line will employ 3 people, the productivity is 1000 kg/h. As additional equipment, a chopper is purchased, which costs about 15,000 rubles.

- Production of bulk and granules with 4 specialists on the line.

The best option for creating a small business would be to purchase an inexpensive unit; it is recommended to choose LPGK and KR-02, which is optimal in terms of price-quality ratio. In addition, the technical equipment of a small plant will include tools such as a crusher, mixer, electronic weighing device, conveyor, control panel, and separator.

The best option for creating a small business would be to purchase an inexpensive unit; it is recommended to choose LPGK and KR-02, which is optimal in terms of price-quality ratio. In addition, the technical equipment of a small plant will include tools such as a crusher, mixer, electronic weighing device, conveyor, control panel, and separator.

In order to start your own business, you will need to prepare a workshop and warehouse. The height of the first must be at least 4.5 meters. And it is important to comply with the basic requirements for the premises:

- Heating up to +5 degrees.

- Ensuring production has sufficient space.

- Compliance with equipment layout diagrams.

Where to get raw materials?

The main raw material is hay, straw and cake. Also during production you will have to use the following components:

- Grain – barley, corn, oats, beans, other crops.

- Several types of flour - herbal, fish, meat and bone.

- Raw materials based on starch.

- Minerals, salt, chalk.

- Chemical elements.

- Vitamins.

- Antibiotics.

- Proteins, microadditives.

The composition of the feed and components largely depend on the intended purpose. You can purchase ingredients from private and public enterprises that collect grain crops and produce the necessary elements - chalk, salts, minerals.

Technological process

Technological operations consist of carrying out sequential actions, the intensity and duration of which depend on the final goal. Pelleted feed is very popular on the market, and the main stages of its production include the following:

- Grinding.

- Distribution, packaging by doses.

- Mixing.

- Production of granules.

- Package.

Hay or straw is used as the primary raw material; it is crushed in several stages. The grain is crushed using a special crusher, then weighed, and it is fed into a special dispenser.

When packaging by dose occurs, various substances are added to the feed. Dosing must be very accurate, since product quality and cost depend on it. After adding feed, the components enter the mixer, where they are mixed until a homogeneous mass is formed.

You can find out more detailed information about the manufacturing process of this product from the following video:

Sales channels

There are many options for marketing pet products:

- intermediaries;

- agricultural farms;

- nature reserves, zoos, nurseries;

- private farmer organizations.

The advantages of selling feed include the fact that purchases are carried out constantly.

Total costs

There are several cost items when starting such a business:

- Purchase of equipment. It will cost more than 1,000,000 rubles (approximately 1,200,000 rubles depending on the place of purchase and condition).

- Installation of equipment– 400,000 rubles, this includes delivery.

- Organizing inventory– 500,000 rubles.

- Warehouse and workshop preparation– this amount will be about 400,000 rubles.

- Registration of a legal entity and other expenses associated with advertising– 100,000 rub.

In total, the cost of opening the project will be 2,400,000 rubles.

However, it is worth considering the monthly costs of renting premises, purchasing materials, equipment maintenance, advertising, taxes, and employee salaries.

Profit calculation

According to statistics, a starting small enterprise for the production of compound feed has a profit of about 30,000-100,000 rubles for 1 month. The payback period is 18 months or 1.5 years.

According to statistics, a starting small enterprise for the production of compound feed has a profit of about 30,000-100,000 rubles for 1 month. The payback period is 18 months or 1.5 years.

On average, the price of feed depends on its quality and can range from 10 to 40 rubles per kilogram. Many companies set a price slightly below the market price in order to gain a customer base. Based on the capacity of the equipment, a minimum of 200 kg of products can be produced per day. With good turnover of goods and minimal stagnation of inventory, the following sales volume can be achieved:

- 200 kg * 30 days = 6,000 kg/month.

The proceeds will be (at a price of 40 rubles per kilogram):

- 6,000 kg * 40 rub./kg = 240,000 rub.

After deducting the costs of renting premises (20,000 rubles), employee wages (75,000 rubles) and other costs (50,000 rubles), you can calculate the amount of net profit:

- 240,000 – 25,000 – 75,000 – 50,000 = 90,000 rubles.

So, with proper organization of production and optimization of inventory levels, it is possible to achieve sustainable development of the enterprise and large amounts of profit.

Reading time 12 minutes

Great idea for a budding entrepreneur. It will allow you to get to know the agricultural sector better. To open such a business, a relatively small investment will be required, which can quickly pay off. But there is nothing to do without the knowledge and help of experts in this industry. Otherwise, it will not be possible to produce a truly high-quality and healthy product for animals.

Relevance of the idea

A business in the production of compound feed will be profitable provided that your own enterprise is properly organized. The agricultural industry itself gives the entrepreneur many prospects. Due to the constant increase in the number of farms, the demand for services for their maintenance is growing. To keep animals, nutritious and balanced feed and other consumables are required.

According to agricultural representatives who have been operating in this area for a long time, feed production is one of the most profitable and promising business formats.

The interest in this idea is also explained by the ease of sale. The demand of agricultural farms for compound feed is not fully satisfied, so even a novice entrepreneur has a chance to gain a foothold in this industry.

But, despite the demand for feed, the newly minted businessman will have to listen to the requests of his clients in order to satisfy their needs. Livestock breeders are not ready to buy low-quality goods. On the contrary, they place increased demands on him.

It is very important that the food produced is balanced, that is, it provides the animals with all the necessary microelements and vitamins. This causes rapid growth of individuals.

It is not at all necessary to work with ready-made recipes. On the contrary, new varieties of food will attract many potential customers. Today, entrepreneurs use grains, legumes and their hybrid varieties to produce feed.

The production of compound feed as a business will become profitable only if truly high-quality products are manufactured. Farmers easily determine nutritional value and balance; they refuse cheap, but poor in composition, products in favor of more expensive ones, but with a higher content of natural protein, vitamins, microelements and other useful components. If an entrepreneur manages to create a really good recipe for compound feed, then his products will be in demand.

The highest level of profitability is typical for large feed mills. But opening them requires serious capital investments - starting from 2,000,000 rubles. But small, home producers also have the right to exist. Only their level of income and profitability will be much more modest.

Types of feed

The production of granulated feed is intended for the production of food for various animals and poultry (chickens, guinea fowl, partridges, and so on). Cereals are used as the basis for such products. And in order for the feed to actively promote the growth of livestock, all kinds of protein additives are added to it. Additionally, the composition includes:

- vitamins (the composition must contain vitamin E; vitamins A and D3 are useful for poultry);

- amino acids;

- microelements (iron, iodine, zinc, calcium and others);

- specialized additives.

The composition of feed should be different for individuals of different ages (the amount of necessary biologically active substances will depend on this). The following indicators will depend on how balanced and complete the food is:

- physical activity;

- rate of growth and development;

- rapid accumulation of fat;

- wool growth rate;

- volume of milk and eggs produced.

A nutritious and balanced diet is especially necessary for those animals and birds that are kept in closed pens and paddocks. Since they do not have enough physical activity, their growth and development must be stimulated with food.

The idea of starting home production of compound feed on a small scale may be of interest to owners of their own farms. In this case, the owner will be able not only to save on the production of food, but also to independently track the composition and select high-quality ingredients that are ideal for his animals and birds.

And yet, most farms prefer to purchase feed from trusted suppliers. That is why the idea of own feed production can bring really good profits to an entrepreneur. They also turn to such companies because the variety of product varieties they have is very large. After all, different types of animals require a special set of nutrients and ingredients. It is clear that pigs and chickens need to be fed different foods. Additionally, feed manufacturers create separate lines within one type in the following areas:

- young animals;

- pregnant individuals;

- nursing animals;

- adults.

- Concentrated. This variety contains a wide variety of nutrients.

- Balanced. These feeds are rich in vitamins and microelements that are beneficial for animals.

- Full blown. Such feed is used by farms for everyday use.

An entrepreneur who decides to open his own business can specialize in one or several types of feed. It is necessary to decide in advance on the form in which the finished product will be produced. The following options are possible:

- Loose. This includes feed of different grinds (fine, medium, coarse).

- Granulated. The food is produced in the form of lumps, round and elongated shapes.

- Briquetted. This variety is characterized by increased feed density. It is available in the form of square or rectangular tiles.

The demand for forms depends on who the feed is being produced for. For example, livestock farms prefer products in briquettes. But for pigs and poultry, farmers actively purchase granular or bulk feed of medium grinding.

It is better for an entrepreneur to decide what type of feed to produce after contacting a specialist. He will not only advise which format to choose, but also help you choose components and composition. After manufacturing the food, a professional will conduct all the necessary tests and laboratory studies in order to draw final conclusions regarding the usefulness and nutritional value of the product.

If necessary, a specialist can also help in drawing up a business plan. Working in the field of feed production, he can assess the value and real cost of products, the demand for it from farms, and the amount of necessary expenses.

If you plan to open a large feed production facility, then it is better to work in several directions at once. For example, specialize in the manufacture of products for different types of animals and birds. The more diverse the offered assortment, the more customers the entrepreneur will be able to attract, ultimately making an excellent profit.

Purchase of necessary raw materials

Entrepreneurs usually use hay, cake or meal as the main raw material for feed. Sometimes it is also high-quality straw, grain, but always without mold and fungal formations. Additionally, the composition includes:

- meat and bone meal;

- salt;

- syrup;

- vitamins;

- protein premixes (vitamin and mineral supplements).

The final feed compositions can vary greatly. Everything will depend not only on who they are produced for, but also on the recipe and technology used.

The technology for producing mixed feed is largely determined by what ingredients are used to make it. If barley is used for bird food, for example, then before adding it, a procedure for exfoliating the grains must be carried out. Whereas for other feeds this procedure is not necessary. For the most part, entrepreneurs today prefer to produce feed in granules. This process consists of several successive stages:

- Raw material grinding. A crusher is used for this step. Ultimately, the raw material is crushed into small particles measuring 10 or 40 mm.

- Dosing. The raw materials obtained at the first stage are sent to the dispenser, and then mixed with various additives. This is a very important step, since the quality of the finished product will ultimately depend on the accuracy of dosing the ingredients.

- Mixing. To combine the various components of the feed, they are sent to a mixer, where they are transformed into a homogeneous mass.

- Granulation. The homogeneous mass from the mixer is sent by conveyor to a special agitator hopper. From it the mixture goes to the press granulator. Using this device, lumps of the same size and shape are made.

- Cooling. This stage allows you to obtain finished products and weed out low-quality goods.

- Packing. Finished products are packaged in bags.

If the entrepreneur is engaged in the production of bulk feed, then stages 4 and 5 are not used, and the finished product is packaged immediately after mixing.

Finding suitable premises

If an entrepreneur decides to open a full-fledged production with an automated line, then he will not be able to do without a spacious room where professional equipment, raw materials and finished products will be located. To work you will need:

- manufacturing facility;

- warehouse for storing raw materials;

- warehouse for storing finished products.

There are no serious requirements for warehouses. The main thing is that it should be dry and not humid. But in the workshop, the ceilings must be at least 4.5 m. It is necessary to correctly position the equipment in the production room. There are established standards and instructions for specific automated lines. It will be difficult for a new entrepreneur to understand this, so it is better to purchase equipment along with subsequent installation and commissioning.

For full and productive work, you will need special equipment for the production of feed. The level of productivity and quality of raw materials will depend on the quality of the equipment used. If you plan to open a small workshop, then a grain crushing machine and a mixer will be enough for the work. But a full-fledged, albeit small, plant will require the purchase of an entire production line. Its cost starts from 900,000 rubles.

If the initial capital is small, then you can limit yourself to purchasing this equipment, and then invest the money received in the purchase of a powerful production line. Equipment that allows you to produce about 3 tons of feed per hour will cost 2,000,000 - 2,500,000 rubles.

The production of granulated feed will require even greater investments. To do this, you will need a specialized line costing 1,500,000 rubles. Its productivity will be equal to 1 ton per hour. And when purchasing a line with a productivity of 3 tons per hour, you will have to spend 3,000,000 rubles, not counting the cost of the shredder.

Sales channels

The success of a feed production plant depends not only on the quality of the finished product, but also on how correctly the entrepreneur can build a sales policy. In this area, this issue is most relevant due to high competition. If a businessman wants his products to be in demand, then he must decide on sales channels at the stage of drawing up a business plan.

Most often, entrepreneurs work with the following feed consumers:

- farms;

- resellers;

- nurseries engaged in breeding animals and birds;

- private individuals;

- zoos.

To ensure that products do not spend a lot of time in warehouses, it is necessary to sell most of them to wholesalers. To do this, you need to conclude supply agreements at the initial stage. It is not necessary to work only with business representatives; you can also offer your services to government organizations.

But there should be few intermediaries involved in the repurchase and subsequent sale of feed, since they usually purchase goods at a lower price than ordinary organizations, because the essence of their business is to generate income in the form of a markup on the product.

The most promising buyers are private agricultural enterprises. Since they are interested in purchasing truly high-quality food, they will be willing to pay a fairly high price for the product.

If the production is located near the city, you can offer your feed supply services to local nurseries and zoos. Fast delivery of products will be one of the most important arguments in favor of their purchase.

If an entrepreneur is engaged in the production of compound feed for his own needs, then he can sell the surplus of finished products on the market or to his neighbors and colleagues.

Calculation of financial results

Any entrepreneur, deciding to open a feed production facility, is interested in how much initial investment he will need. The most serious cost item in this case will be the purchase of specialized equipment. For a large automated enterprise you will need about 2,000,000 - 3,000,000 rubles.