Offshore oil and gas production and its prospects. Platforms on the high seas: theory and practice of construction Oil rigs in the ocean

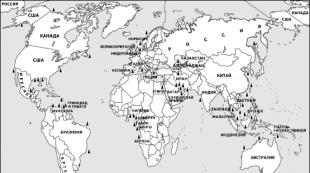

Oil and gas production in recent decades has been supplemented by the discovery of hydrocarbon (HC) accumulations in seas and oceans. Exploration work and production are carried out in different parts of the world: in inland seas and bays - the Caspian (CIS), the Mexican (USA, Mexico), the Maracaíba Lagoon (Venezuela), the Persian Gulf (Saudi Arabia, Kuwait, Qatar, Iran, etc.), in the North (Netherlands, Great Britain, etc.), Mediterranean (Egypt, France, etc.) seas; in the Pacific Ocean - off the coast of Alaska, California (USA), Latin America (Peru) and Japan; in the Atlantic Ocean - off the coast of Latin America (Trinidad, Argentina, Brazil), Africa (Guinea, Nigeria, Gabon, Angola, etc.); in the Indian Ocean - off the coast of South and Western Australia and in the Bay of Bengal (Bangladesh); in the Java Sea (Indonesia); in the Arctic Ocean - off the coast of Northern Alaska, etc.

Particularly significant discoveries of marine accumulations were made in the North Sea, Maracaíba Lagoon, in the Persian Gulf, off the coast of Alaska, etc.

Some of the largest oil and gas facilities being developed in the North Sea include: Ekofisk, Fortis, Montrose, Oak, Argill, Lehman, Indefatigable, etc.

The largest oil and gas accumulation zone, Bolivar, was discovered in the Maracaib Lagoon, which unites a number of oil accumulations with total reserves of more than 4 billion tons. This facility operates over 7 thousand wells.

A number of significant oil and gas accumulation zones have been identified in the Persian Gulf, including large oil accumulations, including Safaniya-Khafji, Manifa, Zuluf, etc.

Under the waters of the Gulf of Mexico, back in 1938, the first offshore oil accumulation, Creole, was discovered, and in the 80s there were more than ten of them, including Eugene Island, Ship Shoal, Motembo, Guanabo, Bacuranao, Cantarel, etc. .

The British oil and gas industry has made enormous progress in the 20 years since the discovery of the first oil deposits in the North Sea, despite the harsh conditions of underwater exploration, becoming one of the largest in the world.

At the end of 1986, 32 oil and 17 gas deposits were being developed offshore in the UK. Operation is carried out from stationary (fixed to the seabed) and floating platforms at sea depths from several tens of meters to 200 m.

Exploration and exploration work for oil and gas is also carried out either from fixed platforms or from floating self-propelled platforms and special vessels. In most cases, to build a permanent platform, an artificial metal frame (foundation) is first built, connected to the seabed. In order to reduce the cost of work, one base is usually used for drilling three or more wells, including inclined ones.

The designs of fixed and floating platforms, as well as drilling vessels for exploration and production of oil and gas, vary. However, in all cases they have the necessary set of equipment and premises. The platforms are equipped with a drilling rig, flushing pumps and other equipment for drilling wells, tools and a supply of powder for flushing fluid, cement and various reagents. The platform has service and living quarters, as well as a landing pad for a helicopter.

Our country also has special vessels for conducting exploration and production of oil and gas at sea. These include the drilling vessels “Valentin Shashin”, “Viktor Muravlenko”, “Mikhail Mirchink”, which were named after famous domestic oil workers who made a huge contribution to the development of the country’s oil and gas complex.

As of the beginning of the 80s (1981), the total annual oil production at sea in foreign countries (excluding socialist countries and the USSR) was 637 million tons, and gas production - 236 billion m 3.

The first five countries producing the largest amount of oil at sea were distributed as follows: Saudi Arabia (148 million tons), Great Britain (89), Mexico (56), Venezuela (54), USA (52), and for gas: USA (137 billion m 3), Great Britain (35.7), Norway (29), Abu Dhabi (7.3), Indonesia (6.5 billion m 3).

According to data for 1985, in developed capital countries and developing countries, 752.3 million tons and 375.9 billion m 3 of gas were extracted from the seabed. At the same time, the highest oil production (million tons) was carried out in the following countries: Great Britain (127.4), Mexico (87.5), Saudi Arabia (75.2), USA (61.5), Venezuela (57), Norway (39.9), and gas production (billion m 3) in the countries: USA (132.2), UK (52.1), Norway (33.6), Malaysia (14.2), Saudi Arabia (14 ), Venezuela (12), Mexico (10).

The number of oil and gas deposits discovered at the beginning of 1986 in developed capital countries and developing countries in offshore areas was 2,419, of which 1,204 were in operation.

The depth of exploration wells at sea ranged from 1920 to 5750 m, and production wells - from 1738 to 4785 m.

Drilling wells and exploiting oil and gas accumulations in offshore areas is a complex and expensive process, as evidenced by comparative data on some technical and economic indicators of offshore and onshore drilling (see Table 4).

Table 4 Technical and economic indicators of offshore and onshore drilling

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru/

Introduction

Geologists study both land and water areas of the seas and oceans.

Natural gas deposits are not only found on land. There are offshore deposits - oil and gas are sometimes found in the depths hidden by water.

Almost 70 percent of the Earth's surface is under water; It's no surprise that exploration companies are turning their attention to bedrock and sediments below sea level as sources of minerals. This so-called "sea mining" is not new. The first offshore exploration took place in the 1960s and 1970s. If most of the Earth's surface is covered in water, why has offshore mining been so slow to gain traction? There are two explanations for this: politics and technological limitations. Before the UN Conference on the Law of the Sea, there was no agreement on how much of the sea shelf belongs to the country and where international waters begin. Now that ownership issues have been settled, technology has advanced, and commodity prices have become sky-high, the issue of offshore geological exploration is becoming more pressing.

Nowadays, the question of improving offshore drilling rigs and how to make offshore oil production more productive and safe is quite acute.

History of offshore oil production

The beginning of offshore oil production dates back to the 1920s, when in the city area. In Baku, 20-30 m from the shore, wells isolated from water were built, from which sea oil was drawn from shallow horizons. Typically, such a well was in operation for several years. In 1891, an inclined well was drilled on the California Pacific coast, the bottom of which deviated at a distance of 250 m from the shore, for the first time revealing productive seams of the marine deposit. Since then, the Californian shelf has become the main target for the search, exploration and production of hydrocarbons under the bottom of the Pacific Ocean.

The world's first offshore oil field appeared in 1924 near the city of Baku, where they began to drill wells into the sea from wooden islands, which later began to be secured with steel piles cemented into the seabed. The basis for drilling wells for the purpose of developing offshore oil fields began to be created in the CCCP in the early 30s. 20th century.

In the late 40s - early 50s, the trestle method of oil production was widely used in the Caspian Sea. Similar offshore oil fields at a sea depth of 15-20 meters were also built in the Gulf of Mexico and in Venezuela. The construction of floating technical equipment for the development of offshore oil fields began mainly in the 50s of the 20th century with the creation of drilling platforms.

Systematic searches for oil deposits in the waters of the seas and oceans began in 1954. In 1965, only 5 countries in the world carried out offshore oil production, in 1968 -21 countries, in 1973 more than 30 countries, in 1984 over 40 countries extract gas and oil from the bottom of the seas and oceans and over 140 search for them on the shelves.

Geography of deposits

Work on oil and gas covers vast areas of the World Ocean. About 1000 deposits have been discovered in the sedimentary strata of the bottom.

The main reserves of oil and gas are located on the continental shelf; in a number of areas of the World Ocean, the continental slope and ocean bed are also considered oil and gas bearing. Oil and gas deposits have been discovered on the shelves of 60 countries. More than 500 deposits are being developed off the US coast, about 100 in the North Sea, and more than 40 in the Persian Gulf. Oil has been discovered and produced on the shelves of North and South America, Europe, Southeast Asia, Africa, Australia, New Zealand and a number of other waters. B CCCP traditional oil-producing area is the Caspian Sea.

A large number of offshore oil and gas fields have been discovered in the Atlantic Ocean and its seas and are being intensively developed. The richest offshore oil and gas areas in the world include the Gulf of Mexico, the Maracaibo Lagoon, the North Sea, and the Gulf of Guinea, which are being intensively developed. Three large oil and gas provinces have been identified in the Western Atlantic:

1) from the Denisov Strait to the latitude of New York (industrial reserves near Labrador and south of Newfoundland);

2) on the Brazilian shelf from Cape Calcañar to Rio de Janeiro (more than 25 fields have been discovered);

3) in the coastal waters of Argentina from the Gulf of San Jorge to the Strait of Magellan. According to estimates, promising oil and gas areas make up about 1/4 of the ocean, and the total potential recoverable oil and gas resources are estimated at more than 80 billion tons.

On the relatively developed shelf of the province, vast oil and gas basins of the North, Irish, Baltic and Mediterranean seas are exploited. In the territories adjacent to the sea of the province, large deposits of hydrocarbons have been explored. A number of deposits are of global importance

The subsoil of the Pacific Ocean is rich in oil and natural gas, but only a small part of it has been studied and developed. Reserves of potential oil and gas resources are estimated at 90--120 billion tons (30--40% of the reserves of the World Ocean). More than 3 billion tons were transferred to the category of explored and recoverable reserves, and 7.6 billion tons were classified as promising and forecast. Underwater development is carried out mainly at depths of up to 100 m and at a distance of 90-100 km from the coast. The main areas of offshore oil and gas production are: the southern part of the California shelf and the waters of Cook Inlet (USA), Bass Strait (Australia), the coastal waters of the Malay Archipelago, Brunei and Indonesia, Bohai Bay (PRC), the waters of the Gulf of Guayaquil (Ecuador) and the shelf zone of Peru. Extensive prospecting and exploration work is being carried out on the Sakhalin shelf, the South China Sea, and in the Strait of Magellan. Oil and gas are produced on the shelves of the provinces, many of the deposits in the coastal zone (are of global importance.) The most intensive development of the maritime industries has been achieved in Indonesia, Malaysia, and Singapore. Indonesia is the region's largest producer of oil and petroleum products (total reserves, including offshore, are about 8 billion tons), and tin ore. Continental offshore oil and gas fields are concentrated off the coast of the islands of Java and Madura, in the northern part of the Western Strait and off the western and eastern coasts of the island of Kalimantan.

Oil and gas production is increasing in the state of Sarawak (Miri), on the shelf of the northwestern part of the island of Kalimantan and off the Malay Peninsula

The subsoil of the northeastern coastal regions and continental shelf of the province is also rich in hydrocarbons (Alaska, the Los Angeles area and the coastal waters of California),

Oil fields are exploited in the coastal states of Mexico (Chiapos), oil reserves have been explored on the coast of Colombia, and oil and gas fields are being developed quite successfully in Ecuador. However, in the countries of the Eastern Province on the Pacific coast, deposits are less common than in the interior and on the Atlantic coast.

Technologies for offshore oil production. Types of Drilling Rigs

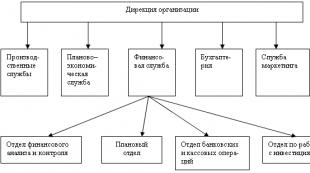

The overall system for oil and gas production in offshore oil and gas fields usually includes the following elements:

· one or more platforms from which production wells are drilled,

· pipelines connecting the platform to the shore;

· onshore oil processing and storage facilities,

loading devices

A drilling rig is a complex technical structure designed to produce oil and gas on the sea shelf.

Coastal deposits often continue on the underwater part of the continent, which is called the shelf. Its boundaries are the shore and the so-called edge - a clearly defined ledge, behind which the depth rapidly increases. Usually the depth of the sea above the edge is 100-200 meters, but sometimes it reaches 500 meters, and even up to one and a half kilometers, for example, in the southern part of the Sea of Okhotsk or off the coast of New Zealand. Depending on the depth, different technologies are used. In shallow water, fortified “islands” are usually built, from which drilling is carried out. This is how oil has long been extracted from the Caspian fields in the Baku region. The use of this method, especially in cold waters, often involves the risk of damage to oil-producing “islands” by floating ice. For example, in 1953, a large ice mass that broke away from the shore destroyed about half of the oil wells in the Caspian Sea. A less common technology is used when the desired area is surrounded by dams and water is pumped out from the resulting pit. At sea depths of up to 30 meters, concrete and metal overpasses were previously built on which equipment was placed. The overpass was connected to land or was an artificial island. Subsequently, this technology lost its relevance.

If the field is located close to land, it makes sense to drill an inclined well from the shore. One of the most interesting modern developments is remote control of horizontal drilling. Specialists monitor the passage of the well from the shore. The accuracy of the process is so high that you can get to the desired point from a distance of several kilometers. In February 2008, Exxon Mobil Corporation set a world record for drilling such wells as part of the Sakhalin-1 project. The length of the well bore here was 11,680 meters. Drilling was carried out first in a vertical and then in a horizontal direction under the seabed at the Chayvo field, 8-11 kilometers from the coast. The deeper the water, the more complex technologies are used. At depths of up to 40 meters, stationary platforms are constructed (Fig. 4), but if the depth reaches 80 meters, floating drilling rigs are used (Fig. 4), equipped with supports. Semi-submersible platforms operate up to 150-200 meters (Fig. 4, 5), which are held in place using anchors or a complex dynamic stabilization system. And drilling ships can drill at much greater sea depths. Most of the “record-breaking wells” were carried out in the Gulf of Mexico - more than 15 wells were drilled at a depth of more than one and a half kilometers. The absolute record for deepwater drilling was set in 2004, when the Transocean and ChevronTexaco drillship Discoverer Deel Seas began drilling a well in the Gulf of Mexico (Alaminos Canyon Block 951) at a sea depth of 3053 meters.

In the northern seas, which are characterized by difficult conditions, stationary platforms are often built, which are held on the bottom due to the huge mass of the base. Hollow “pillars” rise up from the base, in which extracted oil or equipment can be stored. First, the structure is towed to its destination, flooded, and then, directly into the sea, the upper part is built on. The plant where such structures are built is comparable in area to a small city. Drilling rigs on large modern platforms can be moved to drill as many wells as needed. The task of designers of such platforms is to install a maximum of high-tech equipment in a minimum area, which makes this task similar to designing a spacecraft. To cope with frost, ice, and high waves, drilling equipment can be installed directly at the bottom. The development of these technologies is extremely important for countries with extensive continental shelves

Interesting facts The Norwegian platform “Troll-A”, a bright “representative” of the family of large northern platforms, reaches 472 m in height and weighs 656,000 tons. (Figure 6)

Americans consider the date of the beginning of the offshore oil field to be 1896, and its pioneer is oilman Williams from California, who drilled wells from an embankment he built.

In 1949, 42 km from the Absheron Peninsula, an entire village called Neftyanye Kamni was built on overpasses built to extract oil from the bottom of the Caspian Sea. Employees of the company lived there for weeks. The Oil Rocks overpass can be seen in one of the James Bond films - “The World Is Not Enough.” The need to maintain underwater equipment of drilling platforms significantly influenced the development of deep-sea diving equipment. To quickly close a well in an emergency - for example, if a storm prevents the drilling ship from remaining in place - a type of plug called a "preventer" is used. The length of such preventers reaches 18 m, and their weight is 150 tons. The beginning of active development of the sea shelf was facilitated by the global oil crisis that erupted in the 70s of the last century.

After the announcement of the embargo by OPEC countries, there was an urgent need for alternative sources of oil supplies. Also, the development of the shelf was facilitated by the development of technologies, which by that time had reached such a level that would allow drilling at significant sea depths.

The Groningen gas field, discovered off the coast of Holland in 1959, not only became the starting point for the development of the North Sea shelf, but also gave its name to a new economic term. Economists called the Groningen effect (or Dutch disease) a significant increase in the value of the national currency, which occurred as a result of increased gas exports and had a negative impact on other export-import industries.

Let's take a closer look at the technologies for drilling wells in offshore areas and the types of drilling rigs.

The following methods of drilling wells in water areas are distinguished (Figure 8):

1. from offshore fixed platforms;

2. gravity offshore stationary platforms;

3. jack-up drilling rigs;

4. semi-submersible drilling rigs;

5. drilling ships.

An offshore stationary platform is a drilling base resting on the bottom of the water area and rising above sea level. Since, upon completion of the well's operation, the MSP remains at the construction site, the offshore well drilling scheme, in contrast to the onshore well construction scheme, provides for the presence of a riser column that isolates the well from the water column and connects the underwater wellhead with the drilling site of an offshore stationary platform. Wellhead equipment (preventers, casing heads, a device for draining flushing fluid from the well to treatment systems) is also installed on the MSP.

Four or five tugs are required to tow the platform to the well site. Typically, other auxiliary vessels (port tractors, escort vessels, etc.) also participate in towing SMEs. In good weather, the average towing speed is 1.5 - 2.0 kt/h.

Gravity offshore stationary platform is a drilling base made of reinforced concrete and steel. It is built in deep-sea bays and then delivered by tugboats to the drilling point for production and exploration wells. The GMSP is intended not only for drilling wells, but also for the extraction and storage of black gold before sending it by tankers to the processing site. The platform is heavy, so no additional devices are required to hold it at the drilling point.

After the development of the field, all wells are mothballed, the installation is disconnected from the wellheads, separated from the seabed and transported to a new point within the given area or to another region of drilling and oil and gas production. This is the advantage of the GMSP over the SME, which, after developing the field, remains in the sea forever.

The jack-up floating drilling rig has a sufficient reserve of buoyancy, which is of great importance for its transportation to the drilling point along with drilling equipment, tools and the necessary supply of consumables. At the drilling site, using special lifting mechanisms and supports, a jack-up rig is installed on the seabed. The body of the installation is raised above sea level to a height inaccessible to sea waves. In terms of the method of installing preventer devices and the method of connecting the drilling site to the underwater wellhead, a jack-up rig is similar to an MSP. To ensure reliable operation of the well, the casing strings are suspended under the rotor table. Upon completion of drilling and after development of the exploration well, liquidation bridges are installed and all casing strings are cut below seabed level.

A semi-submersible floating drilling rig consists of a hull, which includes the drilling platform itself with equipment and pontoons connected to the platform by stabilizing columns. In the working position at the drilling point, the pontoons are filled with the calculated amount of sea water and submerged to the calculated depth under water; in this case, the effect of waves on the platform decreases. Since the SSDR is subject to pitching, it is impossible to rigidly connect it to the underwater wellhead using a riser column. Therefore, to prevent destruction of the connection between the wellhead and the SSDR, the riser column includes a telescopic connection to the sealing unit and sealed swivel joints of the FOC. with a floating craft and underwater wellhead blowout prevention equipment. The tightness of the moving elements of the riser column must ensure isolation of the well from sea water and safety of work under acceptable operating conditions.

The SSDR is delivered to the drilling point using tugboats and held there by an anchor system during the entire period of drilling and testing the well. Upon completion of its construction, the SSDR is removed from the drilling point and transported to a new location

When constructing deep offshore oil and gas wells, a drilling vessel is used, on which all drilling and auxiliary equipment is mounted and the necessary supply of consumables is located. At the drilling point, the BS proceeds under its own power; its speed reaches 13 kt/h (24 km/h). The vessel is held above the drilling point using a dynamic positioning system, which includes five thrusters and two lead propellers that are constantly in operation.

Subsea blowout prevention equipment is installed on the seabed after the BS is placed at the drilling point; it is connected to the wellhead using a riser column with a diverter, two swivel joints and a telescopic connection to compensate for the vertical and horizontal movements of the drilling vessel during the well construction process.

The main factor influencing the choice of the type of floating drilling equipment is the depth of the sea at the drilling site. Until 1970, jack-up drilling rigs were used to drill wells at depths of 15-75 m, currently - up to 120 m or more. Semi-submersible floating rigs with an anchor holding system above the mouth of the well being drilled are used for geological exploration at water depths of up to 200 -300 m or more.

Drilling ships, due to their higher maneuverability and speed of movement, greater autonomy compared to SSDRs, are used when drilling prospecting and exploration wells in remote areas at water depths of up to 1500 m or more. The large reserves of consumables available on the vessels, designed for 100 days of operation of the installation, ensure successful drilling of wells, and the high speed of the vessel's movement ensures their rapid relocation from a drilled well to a new point. Unlike SSDRs, BSs have greater limitations in operation depending on sea conditions. Thus, when drilling, the vertical pitch of drilling vessels is allowed up to 3.6 m, and for SSDR - up to 5 m. Since SSDR has greater stability (due to the immersion of the lower pontoons to the design depth) compared to drilling ships, the vertical pitch of SSDR is 20--30% of the wave height. Thus, drilling wells with SSDR is carried out at significantly higher sea conditions than when drilling with BS. The disadvantages of a semi-submersible floating drilling rig include the low speed of movement from a drilled well to a new point. A new direction in underwater oil production is the creation of underwater production complexes (Fig. 9), which create normal atmospheric conditions for the work of operators. Equipment and materials (cement, clay, pipes, units, etc.) are delivered to drilling platforms by supply vessels. They are also equipped with decompression chambers and the necessary equipment for diving and a number of auxiliary operations. Produced oil is transported to shore using offshore pipelines, which are laid in the open sea using specialized pipe-laying vessels. Along with pipelines, systems with road berths are used. Oil is supplied to the berth through an underwater pipeline and then supplied to tankers through flexible hoses or risers.

Drilling for oil and gas in Arctic conditions

Drilling for oil and gas in Arctic conditions has its own characteristics and depends on ice conditions and sea depth.

There are 3 ways of drilling in these conditions: from a floating vessel; co ice; c a platform or vessel installed on the bottom that can withstand the effects of ice. Extensive experience in ice drilling has been accumulated in Canada, where they drill at depths of up to 300 m. In the absence of a powerful ice base and at significant depths, massive floating caisson structures are used, equipped with thrusters, capable of operating without a person and withstanding the action of moving ice, waves, and wind. and currents. Auxiliary vessels are used to break up large ice floes and remove icebergs. In the presence of large icebergs, the removal of which is difficult, the caisson operational structure is disconnected from the bottom and moved to the side using thrusters.

Main oil production areas

Already, about 20% of oil is extracted from the bottom of seas and oceans. By some estimates, half of the Earth's oil reserves are located offshore and in deeper waters.

In the Gulf of Mexico, signs of oil were found at a depth of more than 3000 m. The main areas of offshore oil production are the Gulf of Venezuela, the shelves of the Gulf of Mexico and the state of California, the Persian Gulf, some areas of the Gulf of Guinea (off West Africa), the North Sea, shoals off the coast of Alaska, Peru, Ecuador, as well as the Caspian Sea, the waters of Lake. Maracaibo and the Gulf of Cook.

Offshore oil production in Russia

Exploration and exploitation of subsea subsoil goes back more than two centuries. Scientists and oil industrialists have long paid attention to the numerous outlets of oil and gas from the bottom of the sea in the coastal waters of some islands of the Absheron and Baku archipelagos, especially in Baku Bay.

In 1781 - 1782 a squadron of Russian ships engaged in studying the Caspian Sea visited the area of the island. Residential. The team noticed a film on the surface of the sea, which was recorded in the logbook of one of the ships. Russian academician G.V. devoted a lot of time to studying the geology of Azerbaijan, oil fields and mud volcanoes. Abich (Fig. 12). While studying the islands of the Caspian Sea, he noticed oil and gas seeps from the bottom of the sea near some of the islands. In his work devoted to the study of mud volcanoes, he, in particular, pointed to the presence of oil and gas in the depths under the bottom of the Caspian Sea in the Neftyanye Kamni area in Bibi-Heybat Bay.

At the beginning of the 19th century. Baku resident Haji Kasumbek Mansurbekov decided to start extracting oil from the bottom of the sea in Bibi-Heybat Bay. For this purpose, in 1803 he built two wells lined with wooden frames, 18 and 30 m from the shore. These wells, which produced significant amounts of oil, were in use until 1825, when they were destroyed by a storm.

After this, interest in offshore oil production arose again at the end of 1873 - beginning of 1874. A group consisting of oil industrialist Robert Nobel, skipper Robert Miller, Libau resident B. de Boer and naval lieutenant Konstantin Iretsky turned to the Mining Administration. They petitioned for the allotment of 10 acres of the seabed in Bibi-Heybat Bay to organize oil production work. This petition met fierce resistance from oil industrialists Zubalov and Jakeli, owners of oil plots on the shore of this bay. They appealed to the Baku governor with a protest, justifying their objections by the fact that the towers would prevent their sea vessels from delivering the necessary materials for drilling and production to the piers built on the shore of the bay. Only in 1877 did the Mining Administration refuse the request to provide land at sea.

The next petitioners were V.K. Zglenitsky, N.I. Lebedev and I.S. Zakovenko, who petitioned various authorities in 1896, 1898, 1900 and 1905 to obtain permission for offshore drilling. In 1896, mining engineer V.K. Zglenitsky submitted a forgiveness to the State Property Management of the Baku Governorate and Dagestan Region, in which he asked to be given a section of the seabed for oil exploration and production. The state property management refused, citing the fact that the sea and the seabed are not under its jurisdiction.

The next time the petition was submitted to the Minister of Agriculture and State Property and was left unanswered. Only after a repeated appeal, the Ministry of Agriculture and State Property forwarded the petition to the Mining Department, which, not understanding the essence of the proposal, spoke negatively. The refusal was justified by the fact that oil produced at sea would be more expensive than on land, the organization of the oil industry at sea would cause great damage to fishing, and the presence of derricks at sea and, possibly, open oil gushers would interfere with shipping. However, the department recognized the need to deeply study the presence of oil reservoirs under the seabed. In 1897, the study of this issue was transferred to the engineer of the Caucasian Ore Mining Department N.I. Lebedev, who with his research confirmed the oil-bearing capacity of the Baku Bay formations. As a result, the Mining Department makes the following decision: “In those parts of the seabed where geological studies have already established the presence of oil and where the presence of oil fields will not cause harm to fishing and navigation, oil extraction may be allowed, but not directly, but after filling it with earth.”

This decision did not force V.K. Zglenitsky abandoned his project, and in 1900 he again petitioned the Caucasian Mining Department to grant him the right to extract oil in Bibi-Heybat Bay. The department sent this petition to the Ministry of Agriculture and State Property with its conclusion, which stated that the project is dangerous in terms of fire and oil production in offshore areas can only be allowed after the creation of an artificial territory by filling up the sea in the designated areas. Project V.K. Zglenitsky was referred to the technical commission of the ministry for consideration. According to the project, wells were drilled from separate sites built on wooden piles driven into the ground. To avoid sea pollution and oil losses in the event of a release, a tank with a capacity of 3,000 tons was built on the base. To transport oil to the shore, it was planned to build an oil barge with a lifting capacity of 3,000 tons with the necessary pumping equipment. The technical commission did not accept the project and, like the Mining Department, spoke in favor of developing offshore oil areas only after they were filled with soil. At the same time, she recognized the possibility of allocating 300 dessiatines (one dessiatine is slightly more than 1 hectare) in Bibi-Heybat Bay for backfilling. After discussing this issue in the Cabinet of Ministers on June 30, 1901, the Mining Department decided to fill up part of the water area of Bibi-Heybat Bay. According to this decision, the 300 dessiatines allocated for backfilling were divided into plots of 4 dessiatines each. It was brought to the attention of oil industrialists about the delivery of these areas at a price of 125 thousand rubles. To manage the filling work, an executive committee was created, consisting of oil industrialists, which began work at the end of 1905, when 50 sites had already been leased.

However, despite the decision of the Mining Department on the possibility of developing offshore deposits only after filling the designated areas with soil, at the end of 1905 engineer N.S. contacted the department. Zakovenko with a petition to allow drilling wells using a floating drilling rig placed on a caisson-pontoon. Although experts praised this project, it was also rejected by the Mining Department, which motivated the refusal by the lack of development of the project. The project of filling the bay was finally abandoned. According to the project, a section of the sea of 300 dessiatines was previously to be fenced off with a stone pier. To supervise the work on filling the bay, the executive committee invited engineer P.N. Pototsky, who worked in Kherson on the construction of a canal at the mouth of the Dnieper.

The construction of the barrier pier, which began in January 1910, was completed in mid-1911, after which the Sormovo company began backfilling. For this purpose, the Sormovo Shipyard built a special dredging caravan consisting of two dredgers with a capacity of 1100 hp each. s, two refulers, six tugs, ten barges with a capacity of 1100 m3 and two auxiliary vessels. The work lasted 8.5 years, and 193 acres (or 211 hectares) of the seabed were filled up. On April 28, 1920, Soviet power was established in Azerbaijan, and on May 24, enterprises involved in oil production and refining were nationalized. From the first days of nationalization, Baku oil workers began to restore and reconstruct the oil industry. Work on filling the bay was also resumed soon. The first stage of backfilling, covering an area of 27 hectares, was completed within two years. Already in 1922, the first exploration wells were laid on the territory reclaimed from the sea. At the beginning of 1923, 10 wells were being drilled. The efforts of oil workers to develop oil fields from artificially created territories have been crowned with success. The first well completed on April 18, 1923 produced a gush of pure oil.

The exceptionally good results obtained during the drilling and operation of the first wells prompted us to increase the pace of development of the backfilled oil area and begin work on backfilling the second stage in accordance with the work developed by P.N. Pototsky project.

The results obtained from drilling wells and studies carried out by geologists showed that rich deposits extend into the sea, far beyond the boundaries of the buried area. Then the idea arose to drill wells from specially constructed islands in the open sea. Back in 1925, a powerful fountain erupted from a well drilled from a separate wooden base built in Bibi-Heybat Bay. Well 61, completed by drilling from this island, is the first in the world drilled in the sea. This successful experience led to the fact that work on the development of oil deposits lying under the seabed continued through the drilling of separate wells.

In the five years after the commissioning of well 61, 262 wells were drilled and 6,600 thousand tons of oil and a significant amount of gas were produced. At first, artificial islands were built by driving wooden piles into the ground with a piledriver mounted on two paired boats - kirzhims. The foundation of one well required up to 300 long piles. The need to import timber from the northern regions of the country, as well as the seasonality of delivery, seriously hampered the progress of work to bring rich oil deposits into exploitation. The disadvantage was that the piles could not be driven in areas of the sea where the bottom was composed of strong rocks and the presence of underwater rocks. Only in 1934, young engineers N.S. Timofeev and K.F. Mikhailov proposed and put into practice a method for constructing offshore individual foundations on metal drilled-filled piles. The development of offshore fields has begun in the coastal waters of the island. Artem.

Thus, it can be stated that the exploration and development of offshore oil fields by methods of creating artificial territories and constructing individual island-type foundations in the sea were first carried out in the USSR in Ilyich Bay (formerly Bibi-Heybatskaya).

Until the beginning of the Great Patriotic War, systematic work was underway to develop the underwater resources of the Caspian Sea. The relocation of drillers and equipment to the east of the country caused by the war led to a sharp reduction in drilling work everywhere, including offshore. With the end of the war and the gradual return of drillers to Azerbaijan, drilling work began again. At sea, exploration and production drilling for a long time was carried out at shallow depths from individual foundations of N.S. structures. Timofeeva, B.A. Raginsky and other oil workers.

Due to frequent storms, work on the construction of the foundations was delayed. This greatly hampered the development of offshore oil and gas fields. Individual wells laid on the shore and carried out by directional drilling in the sea did little to maximize production from the Caspian waters. All this led to the emergence of a block foundation design, individual components of which were manufactured at a mechanical plant and transported to the shore, closer to the planned drilling zone. The first such drilling rig designed by L.A. Mezhlumova was installed in the area of Fr. Artem in 1948. With the creation of a new, more efficient stationary foundation, drilling work at sea gained a wide scope. The post-war country's needs for oil necessitated the commissioning of new rich fields. In this regard, the issue of exploration and production of oil in offshore waters has become acute.

Taking into account the availability of positive geological and exploration data, in 1948 it was decided to plant an offshore exploration well in the Neftyanye Kamni area. The first industrial gush of oil at Neftyanye Kamni struck on November 7, 1949. This was an event that heralded the discovery of a unique oil and gas field in the Caspian Sea.

Of great importance in the accelerated development of offshore oil and gas fields was the introduction of offshore platforms and high-performance methods for their construction, developed by B.A. Raginsky, A.O. Asan-Nuri, N.S. Timofeev and others. In 1951, construction of overpasses began at the Oil Rocks field. By 1964, more than 200 km of overpasses and overpass platforms had been built in the sea, sea depths of up to 40 m had been developed. Based on large-scale exploration and development of offshore oil areas, a new branch of the oil and gas field had emerged - the development of offshore oil and gas fields. Based on the generalization and systematization of experience in the development and exploitation of offshore oil and gas deposits, a number of provisions and principles of engineering and technology for oil and gas production at sea were developed. Currently, the length of overpasses in the Caspian Sea exceeds 350 km, depths of up to 70 m have been developed. In 1980, the floating semi-submersible drilling rig (SSDR) "Kaspmorneft" was built, commissioned by Mingazprom by the company "Rauma Repola" in Finland and equipped with powerful drilling equipment , which allows you to drill exploration wells to a depth of 6000 m in a water thickness of up to 200 m.

During development from 1949 to 1980, over 260 million tons of oil and more than 135 billion m3 of gas were produced from the fields of the Southern Caspian Sea. In the USSR, already in 1978, a special department was created under Mingazprom for the development of offshore fields. In 1990, almost 100 thousand people worked in the department.

Growth trend in oil and gas production (1928-1965) (Figure 13)

Offshore oil and gas production, which began in the Caspian Sea, has now spread to other seas and oceans. Intensive consumption of fuel and energy raw materials was the reason that by the beginning of the 1980s. More than 100 of the 120 countries with access to the sea were searching for oil and gas on the continental shelf, and about 50 countries were developing offshore oil and gas fields. According to the Geneva Convention of 1958, the sea area up to a depth of 200 m adjacent to the coastline belongs to the territory of the country, and beyond that the free zone begins. The largest offshore production areas are the Gulf of Mexico, Lake. Maracaibo (Venezuela), the North Sea and the Persian Gulf, which account for 75% of world oil production and 85% of gas. Currently, the total number of offshore production wells worldwide exceeds 100,000, and oil is extracted from sea depths of up to 300 - 600 m. The USA, Norway and the UK are ahead in terms of the pace of offshore drilling and oil production from offshore fields. In the USA, shelf exploration is subsidized by the government, and subsidies amount to up to 80% of the total cost of the project. Over 20 years, from 1960 to 1980, oil production on the continental shelf increased 7 times - from 110 to 720 million tons and amounted to up to 25% of all world production. Currently, oil produced from offshore fields accounts for about 30% of all world production, and gas - even more. Oil production on the shelf is carried out using submersible and semi-submersible drilling platforms. In our country, there are few drilling rigs that are used in Western countries, as they are expensive. In addition, these are complex engineering structures. One of the largest installations is 170 m high, weighs 10 million tons, has four supports, each of which could accommodate a three-section nine-story building. It is operated by a crane with a lifting capacity of 2.5 thousand tons. It can lift a five-story, 100-apartment building. Up to 48 wells can be drilled from such an installation, and production is up to 8 million tons of oil, which is equal to the entire annual production of the Caspian Sea. The cost of such an installation is $2 billion. Russia operates four floating drilling rigs (Fig. 14), purchased at one time in Canada. They are installed in the Barents Sea and Sakhalin. To develop the Russian continental shelf, a consortium was created, which included Japan and the United States.

offshore oil production drilling

Offshore drilling conditions

The process of drilling wells at sea is influenced by natural, technical and technological factors (Figure 15). The greatest influence is exerted by natural factors that determine the organization of work, the design of equipment, its cost, the geological information content of drilling, etc. These include hydrometeorological, geomorphological and mining-geological conditions.

Hydrometeorological conditions are characterized by sea waves, its ice and temperature regimes, fluctuations in water level (high tides, surges) and the speed of its flow, visibility (fogs, low clouds, snowstorms, precipitation). For most of the seas washing the shores of Russia (Japanese, Okhotsk, Bering, White, Barents, Tatar Strait), the following average frequency of wave heights is characteristic, %: up to 1.25 m (3 points) - 57; 1.25 -- 2.0 m (4 points) -- 16; 2.0 -- 3.0 m (5 points) -- 12.7; 3.0 -- 5.0 (6 points) -- 10. The average frequency of wave heights up to 3.0 m in the Baltic, Caspian and Black Seas is 93%, 3.0 --5.0 m -- 5%. The coastal zone of the Arctic seas is covered with stationary fast ice most of the year. Navigation here is possible only 2 - 2.5 months a year. In severe winters, in closed bays and bays of the Arctic seas, drilling from ice and fast ice is possible. Drilling from ice is dangerous during periods of melting, breaking and drifting. At the same time, drifting ice smoothes out the waves. This is especially typical for the Kara, Laptev, East Siberian and Chukchi seas. Here, the average frequency of wave heights up to 3 m is 92%, 3 - 5 m - 6.5%. For drilling in offshore areas, negative air temperatures are dangerous, causing icing of the drilling base and equipment and requiring a lot of time and labor to get the power equipment ready after settling. The time for drilling at sea is also limited by reduced visibility, which during the ice-free period is more often observed at night and in the morning. The impact of reduced visibility on offshore drilling can be reduced by using modern radar guidance and radio communications technology on the rig and onshore. Drilling foundations are subject to the action of currents in the sea associated with wind, tidal and general water circulation. Current speeds in some seas reach high values (for example, in the Sea of Okhotsk up to 5 m/s). The influence of currents changes in time, speed and direction, which requires constant monitoring of the position of the floating drilling rig (MODU) and even the rearrangement of its anchors. Operation at currents above 1 m/s is possible only with reinforced anchor devices and means of their distribution. In the zone of high tides, the bottom of a large part of the coastal waters is exposed and the so-called inaccessibility zone into which drilling ships cannot deliver installations sharply increases. The height of tides even in neighboring seas and their areas is different. Thus, in the Sea of Japan, the tides are practically not noticeable, but in the northern part of the Sea of Okhotsk they reach 9-11 m, forming many kilometers of strips of bare bottom at low tide. Geomorphological conditions are determined by the outlines and structure of the coast, the topography and soil of the bottom, the distance of the well locations from land and developed ports, etc. The shelves of almost all seas are characterized by small bottom slopes. Isobaths with a mark of 5 m are located at a distance of 300-- 1,500 m from the coast, and with a mark of 200 m - 20--60 km. However, there are gutters, valleys, depressions, and banks. The bottom soil, even in small areas, is heterogeneous.

Sand, clay, silt alternate with accumulations of shells, gravel, pebbles, boulders, and sometimes with rock outcrops in the form of reefs and individual stones. At the first stage of development of offshore deposits of solid minerals, the main object of geological study is areas in coastal areas with water depths of up to 50 m. This is explained by the lower cost of exploration and development of deposits at shallower depths and a fairly large shelf area with depths of up to 50 m. Single exploration wells drilled in depressions up to 100 m deep. The main shelf zone explored by geologists is a strip ranging from hundreds of meters to 25 km wide. The distance of well placement points from the shore when drilling from ice fast ice depends on the width of the fast ice strip and for the Arctic seas reaches 5 km. The Baltic, Barents, Okhotsk Seas and the Tatar Strait do not have conditions for quickly sheltering watercraft in the event of a storm due to the lack of closed and semi-closed bays. Here, it is more effective to use autonomous MODUs for drilling, since when using non-autonomous installations it is difficult to ensure the safety of personnel and the safety of the installation in stormy conditions. Working near steep, steep and rocky shores that do not have a sufficiently wide beach area poses a great danger. In such places, when a non-autonomous MODU breaks away from its anchors, its death is almost inevitable. In the shelf areas of the Arctic seas there are almost no equipped berths, bases and ports, so the issues of life support for drilling rigs and ships serving them (repair, refueling, shelter during a storm) must be given special importance here. In all respects, the best conditions are found in the Japanese and Russian inland seas. When drilling in areas remote from possible shelter sites, a weather forecast warning service must be well established, and the watercraft used for drilling must have sufficient autonomy, stability and seaworthiness. Mining and geological conditions are characterized mainly by the thickness and physical and mechanical properties of the rocks intersected by the well. Shelf deposits are usually composed of loose rocks with inclusions of boulders. The main components of bottom sediments are silts, sands, clays and pebbles. Sandy-pebble, loam, sandy loam, sandy-silty, etc. deposits can form in different proportions. For the shelf of the Far Eastern seas, bottom sediment rocks are represented by the following types, %: silts - 8, sands - 40, clays - 18, pebbles - 16, others - 18. Boulders are found within 4-6% of the drilled wells and 10-12% of the total number of wells. The thickness of loose sediments rarely exceeds 50 m and varies from 2 to 100 m. The thickness of layers of certain rocks ranges from several centimeters to tens of meters, and the intervals of their occurrence in depth do not obey any pattern, with the exception of silts, which are in most cases located at bottom surface, reaching 45 m in “quiet” closed bays. The silts in the upper layers are in a liquefied state, at great depths they are somewhat compacted: shear resistance is 16 - 98 kPa; internal friction angle 4 -- 26°; porosity 50 -- 83%; humidity 35 -- 90%. Sands have adhesion that is almost zero, an angle of internal friction of 22 - 32°, and a porosity of 37 - 45%. The shear strength of clays is 60 - 600 kPa; consistency index 0.18--1.70; porosity 40 -- 55%; humidity 25 - 48%. Bottom sediment rocks, with the exception of clays, are incoherent and easily destroyed during drilling (II - IV categories in terms of drillability). The walls of the wells are extremely unstable and, without fastening, collapse after they are exposed. Often, due to significant water content of rocks, quicksand are formed. Lifting cores from such horizons is difficult, and drilling them is possible mainly by advancing the bottom of the well with casing pipes.

Platform disasters

Accidents during oil production (Figure 17) on the continental shelf Gas and oil production on the sea shelf is inevitably accompanied by various types of accidents. These are sources of severe pollution of the marine environment at all stages of work. The causes and severity of the consequences of such accidents can vary greatly, depending on the specific set of circumstances, technical and technological factors. It can be said that each individual accident unfolds according to its own scenario.

The most common causes are equipment failure, personnel errors and extreme natural phenomena such as hurricane winds, seismic activity and many others. The main danger of such accidents, spills or releases of oil, gas and a host of other chemicals and components, leads to severe consequences for the environment. Such accidents have a particularly strong impact when they occur close to the coast, in shallow waters and in places with slow water turnover.

Accidents at the drilling stage Such accidents are associated primarily with unexpected releases of liquid and gaseous hydrocarbons from the well as a result of the drill passing through zones with high pressure. Perhaps only oil spills from tankers can compare with such accidents in terms of force, severity, and frequency. They can be conditionally divided into two main categories. The first involves an intense and prolonged blowout of hydrocarbons, which occurs when the pressure in the drilling zone becomes abnormally high and conventional plugging methods fail. This happens especially often when developing new fields. Just such an accident happened during the development of the Sakhalin-1 field. The second type of incident is associated with regular episodes of hydrocarbon leakage throughout the drilling period. They are not as impressive as fairly rare blowout events, but the impact they have on the marine environment is quite comparable due to their frequency

Pipeline accidents

Complex and extensive underwater pipelines have been and remain one of the main environmental risk factors in offshore oil production. There are several reasons for this, they vary from material defects and fatigue, to tectonic movements of the bottom and damage from anchors and bottom trawls. Depending on the cause and nature of the damage, a pipeline can be the source of a small or large leak or release of oil.

Major accidents on oil production platforms

March 1980 The Alexander Keilland oil platform in the North Sea breaks apart due to "metal fatigue" and capsizes. 123 people died.

· September 1982. The oil production platform Ocean Ranger (USA) capsized in the North Atlantic, killing 84 people.

· February 1984: One person is killed and two others are injured in an explosion on an oil platform in the Gulf of Mexico off the Texas coast.

· August 1984: An explosion and fire on a Petrobras platform off the coast of Brazil kills 36 people and injures 17.

· July 1988 The largest disaster in history - on Occidental Petroleum's Piper Alpha oil production platform, an explosion that followed a gas leak killed 167 people.

· September 1988: 4 people were killed in the explosion and subsequent flooding of an oil production platform owned by Total Petroleum Co. (France), near the coast of Borneo.

· September 1988 Explosion and fire on the Ocean Odyssey oil platform in the North Sea, killing one person.

· May 1989: Three people are injured in an explosion and fire on a Union Oil Co. oil production platform. (USA) off the coast of Alaska.

· November 1989 Penrod Drilling Co. oil platform explosion. in the Gulf of Mexico, 12 people were injured.

· August 1991 Explosion at a Shell-owned oil production facility

· January 1995 Explosion on a Mobil-owned oil platform off the coast of Nigeria, killing 13 people.

· January 1996: 3 people were killed and 2 injured in an explosion on a Morgan oil platform in the Gulf of Suez.

· July 1998: 2 people were killed in an explosion on the Glomar Arctic IV oil platform.

· January 2001: 2 people died in a fire on a Petrobras gas platform off the coast of Brazil.

· March 16, 2001. P-56, the largest oil platform in the world, which belonged to Petrobras, exploded off the coast of Brazil. 10 oil workers were killed. On March 20, after a series of devastating explosions, the platform sank, causing irreparable damage to the region's environment and total losses, which experts estimate (including lost profits) to exceed a billion US dollars. In Brazil, this message caused mass protests: over the past three years, 99 emergency situations occurred at the company’s enterprises.

· October 15, 2001. According to environmentalists, the extensive construction of oil platforms on the Sakhalin shelf has endangered the population of the protected gray whale. The Sakhalin Energy oil company began dumping toxic waste from its production into the Sea of Okhotsk.

Similar documents

Causes and severity of consequences of accidents during gas and oil production on the sea shelf. Designs of semi-submersible platforms. Scheme of underwater well injection. Features of offshore oil production. Characteristics of the semi-submersible drilling rig Glomar Arctic IV.

abstract, added 10/11/2015

Development of oil fields. Equipment and technology of oil production. Flowing operation of wells, their underground and major repairs. Collection and preparation of oil in the field. Safety precautions when performing work on servicing wells and equipment.

practice report, added 10/23/2011

General information about the oil industry, both in the world and in Russia. World oil reserves, its production and consumption. Consideration of the territorial organization of oil production and refining in the Russian Federation. The main problems of industry development in the country.

course work, added 08/21/2015

Methods of search and exploration of oil and gas fields. Stages of prospecting and exploration work. Classification of oil and gas deposits. Problems in searching for and exploring oil and gas, drilling wells. Justification for laying delineating exploration wells.

course work, added 06/19/2011

Preparatory work for the construction of a drilling rig. Features of drilling mode using rotary and turbine methods. Methods of oil and gas production. Methods of influencing the bottomhole zone. Maintaining reservoir pressure. Collection and storage of oil and gas in the field.

course work, added 06/05/2013

Geological foundations of prospecting, exploration and development of oil and gas fields. Oil: chemical composition, physical properties, saturation pressure, gas content, field gas factor. Technological process of oil and natural gas production.

test, added 01/22/2012

Orohydrography of the Samotlor oil field. Tectonics and stratigraphy. Reservoir properties of productive formations. Properties of oil, gas and water in reservoir conditions. Oil production technology. Methods of dealing with complications used at OJSC "CIS".

course work, added 09/25/2013

Choice of oil production methods. Flow well equipment diagram. Gas lift and pumping methods of oil production. Construction of a borehole jet pump installation. Criteria for assessing the technological and economic efficiency of operating methods.

presentation, added 09/03/2015

Oil deposits in the bowels of the Earth. Oil exploration through geological, geophysical, geochemical and drilling operations. Stages and methods of the oil production process. Chemical elements and compounds in oil, its physical properties. Petroleum products and their applications.

abstract, added 02/25/2010

General characteristics, history and main stages of development of the field under study. Equipment and tools used in the exploitation of oil and gas fields. Professional rights and responsibilities of an oil and gas production operator.

Workers and personnel travel to the village of Nogliki, a stronghold of SE in the north of Sakhalin, by train, in the company's private carriage. An ordinary compartment car - nothing special, although a little cleaner than usual.

Each passenger is given the following lunch box:

Upon arrival in Nogliki, everyone is met by a supervisor and decides what to do next - either a temporary camp, or an airport - by helicopter, or (if the weather is unflyable) by boat. We were sent straight to the airport. To fly in a helicopter, you must take a helicopter rescue course (HUET) in advance in Yuzhno-Sakhalinsk. During this training, they put on special thermal suits equipped with a breathing system and turn you upside down in a swimming pool, in a simulated helicopter cabin, but that’s another story again...

At the airport, everyone undergoes a personal search (including dog handlers)

Pre-flight briefing describing the situation if the helicopter still crashes and putting on rescue suits.

The suits are terribly uncomfortable, but if the helicopter crashes, they can keep you afloat and keep your body warm until rescuers arrive. True, if you get out of a sinking helicopter in this suit...

The platform is located 160-180 km from Nogliki. The helicopter covers this distance in 50-60 minutes, flying all the time along the shore to minimize the risk of falling into the water, and along the way flying another platform of the Sakhalin-2 project, Molikpaq.

After landing on the helipad, you go down to the induction room:

All! Now you are on an offshore oil production platform, a piece of land in the sea, and there is no escape from this fact.

How to work here?

The PA-B platform operates around the clock and life here does not stop for a second. 12 hour day shift and 12 hour night shift.

I worked during the day, although some say that at night it is calmer and there is no daytime bustle. All this, of course, is addictive and after a couple of days you already feel like a cog in a huge mechanism, and an even better comparison is like an ant in an anthill. The worker ant woke up at 6 in the morning, had breakfast with what the ant cook had prepared, took the work order from the ant supervisor and went to work until the evening, until the replacement ant came to replace him... At the same time, it’s like... then everything unites.

After 3 days I already knew almost everyone by sight...

And I felt as if we were all part of one whole, practically relatives.

But there are 140 people working on the platform (that’s exactly how many people should be on the platform and not one more, so that the lifeboats “alpha”, “betta” and “gamma” could evacuate everyone. That’s why we were transferred to spend the night on the ship for a couple of days). A strange feeling... it all felt like one continuous, continuous day.

I woke up, went to the dining room, greeted the person from the night shift, for whom it was dinner, he went to bed, and in the evening we met again in the dining room, only he was already having breakfast and I was having dinner. For him it was already a different day, but for me it was the same! And so again and again... a vicious circle. So day after day, night after night, a week passed.

How to live here?

In principle, the platform has all the conditions for a comfortable stay and free time. All conditions have been created here so that a person does not bother himself with everyday problems, but completely devotes himself to two activities - work and rest.

Once you have been assigned to a cabin, you can be sure that upon arrival there will be a crib waiting for you with fresh bed linen already made up, which is changed every few days. Cabins are cleaned and vacuumed regularly. They come in 2 types: “2+2” and “2”. Accordingly, for 4 people and for two.

As a rule, half of the residents work on the day shift, the rest on the night shift, so as not to interfere with each other. The furnishings are spartan - a minimum of furniture due to the lack of free space, but everything is very ergonomic and efficient. Next to each room there is a shower with toilet.

Dirty items are washed in the laundry room.

When you check in, you are given a mesh bag with your cabin number written on it. You put your dirty laundry in it, and then just bring it to the laundry room and after a few hours, fresh-smelling and ironed laundry awaits you.

Work overalls are washed separately in special solutions; household chemicals do not remove oil and other associated amenities.

On each floor of the residential module there is a point with free Wi-Fi (naturally, all social networks are blocked). There is also a computer class - 4 computers for general Internet access and other needs. They are usually used by washerwomen to play solitaire.

There is also a small gym (by the way, quite good):

Billiards:

Table tennis:

Cinema hall:

(the guys attached a Playstation to the projector and raced at dinner) in which in the evening they show something from the newly expanded DVD collection.

A few words about the canteen...

She is o.f.i.g.i.g.e.n.n.a. During my week on the platform I gained 3 kege.

This is because everything is very tasty, unlimited and free =)

During the week, I don’t remember the menu being repeated, but on Oilman’s Day it’s just a celebration of the belly: a bunch of shrimp, scallops and Baltic “nulevka” are worth the batteries!

Smoking on the platform is only allowed in strictly designated areas.

Moreover, each such room has a built-in electric lighter, since the use of lighters and matches is prohibited.

It seems that they cannot be transported and will be confiscated at Noglik airport. It is also prohibited to use cell phones, but except for the residential module and only as an alarm clock. And in order to photograph anything outside the residential module, you will have to write out a special outfit, go through gas permit training and take a gas analyzer with you.

As I already mentioned, for the first few days we lived on the support ship "Smit Sibu" due to the fact that there is a limit of people on board due to the limited number of places in the lifeboats in case of emergency evacuation.

"Smit Sibu" constantly runs from "Molikpaq" to "PA-B" in case of emergency. To reload onto a ship, a “frog” device is used:

This thing really looks like a frog - a non-sinking cabin, with an iron base and chairs inside. Before each transfer, you again need to put on survival suits.

Frog is hooked onto the crane and dragged onto the ship. The sensations are quite sharp when you are lifted to the height of the 9th floor in an open cabin swaying in the wind and then lowered on board. For the first time, I couldn’t hold back a cry of delight at this free “attraction.”

Unfortunately, photography is strictly prohibited in the area 500 meters from the platform - it’s a safety zone, and I don’t have any photos from the frog with a view of the platform. There was nothing particularly interesting on the ship - it didn’t rock much, for breakfast they fed fresh caviar and boiled eggs and macaroni and cheese, and the sockets everywhere were 120 volts and flat like in Japan. There was always the feeling that you were visiting someone else’s house. Maybe the crew created such a mood...

In the evening, the only entertainment was to walk around the upper deck and watch movies.

For the first time I saw a sunset on Sakhalin from the sea, when the sun goes behind the island.

And at night they came very close to Molikpak. Millions of seagulls were circling around, and the torch was burning at full power - the pressure was probably being released. I managed to click a piece of the platform from the porthole:

Well, in the morning we again had to put on rescue suits, climb into the “frog” and back onto the platform.

On one of the last days, I managed to get permission to take photographs at the helipad

And on the upper deck. Flare system with pilot burner:

Many people ask why so much associated gas is flared, because it can be used for various purposes! Firstly, not a lot, but a small part. And secondly, do you know why? So that in the event of an emergency it is possible to safely relieve gas pressure through the flare system, burn it and avoid an explosion.

And this is a drilling module. It is from this that the drilling process is carried out, see how big it is!

The helicopter picking up personnel comes in to land:

The scheduled loading of passengers flying to Nogliki is underway:

The way back home seemed much faster and shorter. Everything was exactly the same, only in reverse order. Helicopter-train-Yuzhno-Sakhalinsk...

91. Oil and natural gas production in the World Ocean

The extraction of oil and natural gas in the waters of the World Ocean has a fairly long history. Marine oil production was carried out using primitive methods back in the 19th century. in Russia (in the Caspian Sea), in the USA (in California) and in Japan. In the 30s. XX century In the Caspian Sea and in the Gulf of Mexico, the first attempts to drill for oil from pile structures and barges were made. The really rapid growth in offshore oil and gas production began in the 1960s. This process accelerated even more in the 1970s and 1980s, as evidenced by the number of countries producing oil and natural gas within the continental shelf. In 1970 there were only about 20 such countries, and in the early 1990s. – already more than 50. Accordingly, global offshore oil production increased (Table 91).

It can be argued that this increase in offshore oil production was due to two main factors. Firstly, after the energy crisis of the mid-1970s. and the sharp rise in oil prices increased interest in shelf basins and fields that had not been used so widely before. They were less depleted and promised certain economic benefits. As noted above, offshore oil and gas production became a striking example of the policy pursued at that time expansion of resource boundaries. Secondly, large-scale development of offshore fields turned out to be possible thanks to a number of technical innovations, and primarily the use of drilling platforms.

Table 91

DYNAMICS OF WORLD OFFSHORE OIL PRODUCTION

From such platforms in the world by the beginning of the 1990s. About 40 thousand offshore wells were drilled, and the drilling depth increased all the time. Back in the early 1980s. 85% of sea oil was obtained at depths of up to 100 m, and there was practically no drilling at depths of more than 200 m. In the mid-1990s. oil production at depths from 200 to 400 m has ceased to be rare, and the maximum depth has increased from 300 m in 1984 to 1000 m in 1994 and 1800 m in 1998. And this is not to mention the fact that exploration drilling is now carried out at depths of 3000 m or more. As drilling depths increased, offshore fisheries began to move further away from the land coastline. At first, this distance usually did not exceed 10–15 km, then 50–100 km, but now in some cases it reaches 400–500 km. In fact, this means that it may already extend beyond the continental shelf.

When considering the dynamics of global offshore oil production, attention is drawn to the fact that recently the rate of its growth has clearly slowed down. The fact is that after overcoming the energy crisis and the entry of the world energy sector into a new, rather lengthy stage of cheap oil, it simply became unprofitable to continue developing many offshore fields, especially in high latitudes, due to higher production costs than on land.

In general, drilling wells in offshore areas is much more expensive than on land, and the cost progressively increases as depth increases. Drilling costs, even at a sea depth of 20–30 m, are approximately twice as high as those on land. The cost of drilling at a depth of 50 m increases three to four times, at a depth of 200 m – six times. However, the amount of drilling costs depends not only on the depth of the sea, but also on other natural factors. In Arctic conditions, for example, production costs exceed the corresponding indicators for subtropical or tropical areas by 15–16 times. Calculations show that even at a price of $130 per 1 ton of oil, its production north of the 60th parallel becomes unprofitable.

That is why previous forecasts for the growth of world offshore oil production have recently been revised downwards (according to some of them, already in 2005 offshore oil should have provided at least 35–40% of all production). The same applies to natural gas, offshore production of which in 2000 amounted to 760 billion m 3 (31%).

Established by the end of the 1990s. The geography of offshore oil and natural gas production is shown in Figure 70. From it we can conclude that such production is carried out in almost 50 places on the globe in all five inhabited parts of the world. But their share, like the share of individual oceans and individual water areas, naturally cannot help but differ. Yes, and over time it changes. Thus, in 1970, approximately 2/3 of sea production came from North and South America and 1/3 from South-West Asia. By 1980, America's share had declined, while Asia, Africa and Europe's had increased. In 1990, of the 760 million tons of global offshore oil production, North and South America accounted for 230 million, Asia 220 million, Europe 190 million, Africa 100 million, and Australia 20 million.

In foreign Europe, offshore fields provide 9/10 of all oil and gas production. This is explained primarily by the special role of the North Sea oil and gas basin, whose fields are actively exploited by Great Britain, Norway and, to a lesser extent, the Netherlands. In addition, small-scale production is carried out in some places in the Mediterranean Sea.

In foreign Asia, the main area for oil and gas production has been and remains the Persian Gulf, where it is carried out by Saudi Arabia, Iran, the United Arab Emirates, Kuwait, and Qatar. In the 1980-1990s. Production has increased noticeably on the continental shelf of the seas of Southeast Asia - in Malaysia, Indonesia, Brunei, Thailand, and Vietnam. Exploration work is also being carried out off the coast of some other countries. The same applies to the shelf zone of the seas washing the coast of China. Among the South Asian countries, India has significant offshore production.

In Africa, the number of countries producing oil and gas within the continental shelf has recently increased significantly. Not so long ago, these included only Nigeria, Angola (on the Cabinda shelf) and Egypt, but then Cameroon, Congo, Gabon were added - in general, the entire strip of the western coast of the mainland from Nigeria to Namibia.

Rice. 70. Oil and gas production areas in the World Ocean

In North America, the main producer of offshore oil and offshore gas is the United States. Offshore fields in this country account for 15% of total oil production and 25% of natural gas production. More than a hundred shelf deposits are involved in exploitation, most of which are located in the Gulf of Mexico, and the rest off the Atlantic and Pacific coasts of the country and in Alaska. In the 1990s. Canada also began extracting offshore oil in the Atlantic areas adjacent to Newfoundland.

In Latin America, Venezuela is located, which was one of the first to begin producing offshore oil (in the Maracaibo Lagoon), and even now these fields provide approximately 4/5 of its total production in the country. However, in the 1980-1990s. Venezuela was first caught up and then surpassed by Mexico, which developed a large oil and gas basin in the Gulf of Campeche in the Caribbean Sea. Other countries producing offshore oil include Brazil and the island nation of Trinidad and Tobago. At the same time, Brazil turned out to be one of the leaders in deep-sea drilling, commissioning it back in the late 1980s. production wells in the Atlantic with a water thickness of more than 400 m. Exploratory drilling for oil and gas is also carried out off the coast of Argentina, Chile, Peru and some other countries of this continent.

In Australia, oil and gas production on the continental shelf began back in the 1960s. - in Bass Strait in the south of the country. After 10–15 years, production levels in this basin began to decline, but this was compensated for by the development of other offshore fields located off the west coast of the country and to the north, in the Timor Sea. Small quantities of marine oil are also produced off the coast of Papua New Guinea.

In Russia in the 1990s. oil and natural gas production in offshore fields (after the transfer of the Caspian deposits, which provided 1.5–2% of the total production of this type of fuel in the USSR, to Azerbaijan) was practically non-existent. However, the prospects for expanding such production are now assessed very highly. They are associated with the already begun industrial development of the two main marine areas. One of them is the Sea of Okhotsk, where near the northeastern edge of Sakhalin Island in the second half of the 1980s. Several large deposits were explored. The other is the Barents and Kara Seas, where also in the 1980s. geologists have discovered an even more important shelf province with large and largest fields - the Shtokman gas condensate field, the Rusanov gas field, the Prirazlomny oil field, etc. According to calculations, on the Sakhalin shelf alone it is planned in the future to increase oil production to 20-30 million tons, and gas production to 15-15 million tons. 20 billion m3 per year (in total, over the entire period of operation, it is planned to produce 1.4 billion tons of oil and 4.2 trillion m3 of gas). And this is not to mention the possibilities of the shelf zone of other Far Eastern seas. The program for the development of oil and gas resources of the Russian Arctic shelf plans to put into operation 11 oil and gas fields with an annual production level of 20 million tons of oil and at least 50 billion m 3 of gas. When assessing the oil and gas potential of the Russian Arctic, one must also take into account the fact that in the entire vast space from the Kara to the Chukchi Seas until the end of the 1990s. not a single exploratory well was drilled. The northern part of the Caspian Sea also belongs to the promising category.

2018-12-14

To develop hydrocarbon reserves in the Arctic, offshore oil production platforms are needed. In Russia, foreign floating drilling rigs are mainly used. They were either purchased or leased. Today, due to US sanctions policy and the geopolitical and economic situation, it is becoming impossible to acquire new platforms from Western companies.

During the Soviet era, 100% of components for drilling rigs were made at domestic enterprises. With the collapse of the Union, some of them found themselves outside of Russia, and some ceased to exist altogether.

But the need to develop Arctic reserves makes us think about the state of affairs in the industry. At the beginning of the 2000s there was no demand for offshore oil platforms. The construction of the Arctic jack-up installation, which was laid down in 1995 and planned to be completed in 1998, was no longer funded. The project was completed at the beginning of this decade.

The most significant of the domestic projects was the Prirazlomnaya oil production platform, built in 2013, during the creation of which industrial, resource and scientific and technical structures solved the tasks assigned to them with the support of the state.