How to start a charcoal production business? Charcoal production: technology, equipment Production of charcoal for barbecues business plan

It is quite difficult to find a business as effective and profitable as the production of charcoal. It allows us to solve problems associated with the shortage of energy raw materials in our country.

It is a renewable resource because trees grow and provide new raw materials. In addition, this type of biological fuel does not pollute the atmosphere, therefore it is considered environmentally friendly.

They learned how to produce such products several centuries ago. There are several varieties of this natural fuel. This product is manufactured using different technologies and raw materials. Nowadays, the need for charcoal has begun to grow, so many entrepreneurs have become interested in this business area.

Production Features

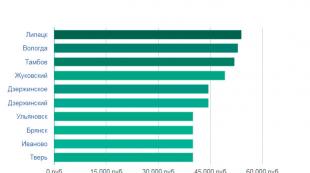

Since the production of such fuel is a fairly promising area of activity, equipment for the production of charcoal is constantly being improved and modernized. Thanks to this, manufacturers are able to obtain high-quality products. If we evaluate the situation on an industrial scale, the largest enterprises are located in the Urals.

Charcoaling without the use of equipment can be pitted and heaped. Such methods do not require capital investment. To get fuel, it is enough to stock up on firewood, water and turf. These methods are used to produce charcoal at home. To produce a high-quality product in large volumes, you need to purchase a special installation. Deciduous trees are more suitable as raw materials for these purposes.

Product yield largely depends on the type of wood. If in a large production it is less than planned, this means that oxygen has entered the furnace. Accordingly, the source material simply burned out. Entrepreneurs who are interested in charcoal production can watch a video of this process on the Internet.

Where to begin?

First of all, as in any other business, for example, it is necessary to draw up a business plan for the production of charcoal.

The following points must be included in it:

- Purchase of equipment;

- Business registration;

- Renting premises;

- Workers' salaries;

- Wood purchase;

- Advertising.

Equipment

At first glance, it may seem that the technology for producing charcoal is a simple process, but in fact, it will require some knowledge. Otherwise you will get a small yield of low quality product.

The whole process is divided into four stages:

- Drying of raw materials;

- Pyrolysis;

- Calcination;

- Cooling.

Several decades ago, such enterprises caused a lot of harm to the environment. Over time, scientists have developed modern innovative technologies with which manufacturers have been able to solve this problem.

To equip a small workshop you will need

- Pyrolysis plant;

- Device for chopping wood;

- Chainsaw;

- Hand tool;

- Scales;

- Packing machine.

Special charcoal kilns for the production of charcoal are designed in such a way that no oxygen enters them. To maintain the required temperature in the furnace, gases formed during the oxidation process are fed into the firebox. These burnt gases are enough for the entire technological process, but only if the wood is not too wet.

Today you can find various installations for the production of charcoal. Most often, businessmen use the equipment that is used for processing waste at woodworking enterprises.

Enterprise registration

Businessmen who plan to create a large enterprise are better off opening an LLC. In this case, they will be able to hire the number of workers they need and expand their production without problems.

Those people who are just trying their hand at it, or who want to turn a hobby, for example, into a business, can register as a private entrepreneur. To do this, select the section - production of OKVED charcoal. Taxes on profits can be paid according to a unified taxation system.

Location of the enterprise and premises

Despite the fact that the furnace for the production of charcoal does not emit any harmful substances that pollute the environment, it is better to locate the enterprise outside the city. Ideally, there will be a sawmill or some kind of woodworking enterprise nearby. This is also required by law.

The area of the land plot on which the enterprise will be located must be no less than 200 square meters. meters, since the main part of the installation is outdoors. In addition, it is necessary to equip a change house for workers. Charcoal production as a business requires large start-up capital, since approximately 700 thousand rubles will have to be spent on equipment for production alone.

You should not rent a plot of land at a high price, as this negatively affects the profitability of production. If your financial capabilities allow it, it is advisable to purchase it as a property.

Sales of products

Since such fuel is not in great demand in our country, the best way to sell it is through foreign partnerships. In European countries, these products are consumed at the proper level, so they are always in demand on the market.

Domestic energy companies also purchase charcoal. It is also consumed by individuals who use stove heating. In addition, the fuel is ideal for cooking shish kebab or barbecue. Pharmaceutical companies and smelter owners may also be interested in such products.

When the business starts to develop, you need to come up with a logo and put it on the packaging. Thanks to this, your products will become recognizable.

Profitability

The payback period and profitability of charcoal production largely depends on the strategy you choose. This is quite a promising and profitable business.

Other types of fuel regularly become more expensive, so the demand for charcoal is constantly growing. This market is developing at a fast pace, so to take your place in it, you need to hurry.

The main advantage of such a business is environmental friendliness and the possibility of sales at a favorable price. And its main drawback is the high level of competition.

Let's sum it up

According to experts, the domestic market is not yet sufficiently saturated with charcoal. Therefore, any entrepreneur who can competently organize his business can provide himself with a stable high income. If you don’t have start-up capital, start a charcoal production business with your own hands. You don't need a lot of money for this. Family members can be involved in the work. This will allow you to save on workers' salaries. Save the profits to eventually buy equipment for producing charcoal.

It is worth noting that this type of fuel is considered elite. Modern people strive for convenience and comfort, but at the same time, they prefer to use environmentally friendly products. Don't miss such a good chance. A well-run business will bring you good profits. This is a direct road to a prosperous, comfortable life.

Such a unique material as charcoal, the production technology of which has been known to the world since ancient times, began to be actively used as an energy source only in the last century.

Charcoal, which is almost 100% carbon, has many advantages and does not harm the environment when burned. The demand for this type of fuel is constantly increasing, which cannot but attract entrepreneurs who are looking for a profitable business idea.

Areas of application of the product

Charcoal has many uses:

- Heating a private house.

- In the production process of crystal, glass, paints, aluminum, boron, electrodes and semiconductors.

- As reducing agents in metallurgical production.

- Used as fertilizer and as food additives for animal feed.

- In the process of grinding and polishing parts used in printing.

- As an insulator in construction.

- As a substitute for graphite in plastic production.

Also, acetic acid, solvents, methyl alcohol and turpentine are made from by-products that are released during the production process.

The main advantage of the charcoal production business is the rapid return on initial capital.

The prospects of the direction are based on the following factors:

- Firstly, business does not require large and unaffordable investments for the entrepreneur.

- Secondly, raw materials are “waste” from wood processing enterprises, which can be purchased at a minimal price.

- Third, the final product is in high demand and has a high markup.

In addition, an entrepreneur does not need to have a special education, and anyone can learn production technology.

Organizational aspects

Depending on the type of wood used in the production process, the following results are obtained: types of charcoal:

- "White coal obtained from hardwood (acacia, oak, hornbeam, birch, ash, etc.). It is considered the highest quality type of coal.

- "Black" coal made from soft wood (alder, willow, linden, aspen, poplar).

- "Red" coal made exclusively from coniferous wood.

The ideal raw material for the production of charcoal is firewood, but their use is expensive.

Most often, production uses waste generated during the processing and harvesting of wood. The presence of modern equipment will allow you to use even peat and sawdust as raw materials.

Technology

Although coal production technology is not complicated, an entrepreneur it is necessary to obtain certain knowledge and gain practical skills. Otherwise, there is a risk of deterioration in quality and a decrease in the “yield” of the final product from raw materials.

Modern technologies simplify the production process without causing any harm to the environment.

The charcoal production process consists of the following steps:

- Drying. The raw materials are dried so that the wood smolders better in the oven.

- Pyrolysis. Key stage of the process.

- Calcination, which is needed to separate gases and resins from charcoal.

- Cooling down.

The pyrolysis technology used in the production process involves burning wood:

- occurs in a closed container in which there should be no access to oxygen,

- at temperatures reaching 500 degrees.

During the combustion process, gases are formed that remain in the chamber and maintain the desired combustion temperature.

Pyrolysis can be carried out exclusively in charcoal kilns (retorts), in which sensors are installed that monitor the degree of combustion and combustion temperature.

The process itself consists of several stages:

- To begin with, the retort is heated to 150 degrees, due to which the wood is dried.

- Next, the temperature rises to 350 degrees, at which the release of gases and charring of the raw material begins.

- By raising the temperature to 500 degrees, we achieve separation of tar and non-condensable gases from the primary coal.

After cooling, the finished charcoal is crushed into small pieces and packaged in bags.

Within a month, you can run from 7 to 30 coal production cycles. The exact number of cycles depends on the volume of raw materials loaded into the furnace.

Is it possible to set up the process at home?

You can start organizing the coal production process at home, but in this case the requirements for raw materials increase. Coal can be produced in this way only from solid wood.

Firing in a container:

- The logs need to be cleared of bark, cut into small shapes and placed in a barrel (bucket). Openings are made in the container to remove gases and resin, then it is tightly closed and placed over a fire, where it is heated to 350 degrees.

- After reaching the desired temperature, the barrel is held over the fire for another 2.5 hours. Then it is removed from the fire, and the lid is opened only after it has completely cooled.

Firing in a pit:

Instead of a barrel, you can also dig a hole and cover it with a sheet of iron. The process of burning wood in a pit also lasts for 2.5 hours.

How the process of producing charcoal in a pit takes place, watch the video:

From 1 m3 of wood, which costs an average of 800 rubles, you can get up to 300 kg of charcoal. If you sell 1 kg of coal for 20 rubles, then in the end you will get 5,200 rubles. income.

The above methods are an excellent option for starting your own business, if the entrepreneur does not have money for modern equipment.

What do you need to get started?

After studying the production process, analyzing the market and making the final decision to start a business, the entrepreneur must draw up a business plan that includes all the stages of creating his own enterprise.

Registration

The positive thing is that charcoal production activities are not subject to mandatory licensing.

However, an entrepreneur needs to go through the process of mandatory state registration:

- As organizational form You can choose an individual entrepreneur or LLC (at the discretion of the entrepreneur).

- Suitable tax regime is the Simplified Taxation System. The choice of object for tax (Revenue - 6% or Profit - 15%) depends on the marginal policy.

If you are going to set a large markup, then it is more profitable to choose “profit” as the object. But if you are going to take the market at the expense of a low markup, then it is more profitable to choose “revenue”.

Workshops and premises

Although modern technologies provide a high level of environmental safety, production must be located outside the city limits. It is better to place it near factories involved in the harvesting and processing of wood, which will reduce the cost of time and money for transporting raw materials.

- The workshop must be located more than 300 meters from residential premises.

- The production area (land plot) must be at least 200 m2.

- The stoves are placed on a plot of land, in the fresh air.

- It is necessary to prepare a place on the site for a warehouse for raw materials and a warehouse for finished products.

- It is also necessary to prepare premises for staff.

To save on running costs It is better to purchase a plot of land.

Equipment

In order to organize a coal production workshop The following set of equipment is required:

- Charcoal kiln– 120,000 rub.

It is the main element of the production process by which waste wood is processed into charcoal. Stationary (installed in one place) and mobile (can be moved from place to place) ovens are available on the market. - Weight dispensers– 20,000 rub.

- Electric generators– 30,000 rub.

- Wood splitter(hydraulic) – 90,000 rub.

- Chainsaw– 15,000 rub.

- Packing machine– 100,000 rub.

Above is a complete set of equipment necessary for organizing a workshop. At the initial stage, you can do without a packaging machine and a wood splitter, which will save significant resources at the stage of starting a business.

Raw materials

The issue of the types of wood used was discussed above.

Here we will give table of wood consumption and charcoal yield.

As can be seen from the table the average “yield” of coal from wood is approximately 28%.

Based on this indicator and production standards, you can plan raw material inventories. It is also worth considering that the consumption of raw materials depends on the equipment used.

If for 1 ton of coal produced in a single-chamber furnace, the consumption is 7 cubic meters of wood, then for three-chamber furnaces the consumption will be much less.

Financial planning

The demand for charcoal is constantly growing, and the markup on finished products is very high. According to entrepreneurs, the charcoal production business is very profitable and has great prospects.

Capital investments - 485,000 rubles.

- Registration – 10,000 rub.

- Equipment – 375,000 rub.

- Purchase of raw materials – 100,000 rub.

Current expenses – 180,000 rub.

- Land rent – 50,000 rub.

- Salary (3 employees) – 80,000 rub.

- Transport costs – 20,000 rub.

- Utilities – 20,000 rub.

- Other expenses - 10,000 rubles.

Profit calculation

Under normal workload of the workshop within a month the minimum output of charcoal will be about 15 tons.

The average cost of 1 kg is 25 rubles. Net income in the case of wholesale sales of the entire batch at the minimum price is 375,000 rubles.

To produce 1 ton, a maximum of 7 m3 of wood is required, costing 8,400 rubles. (7m3*1200 RUR/m3). The total cost of raw materials to obtain 15 m3 of product will be 126,000 rubles.

Net profit= 375,000 rub.-126,000 rub.-180,000 rub. = 69,000 rub. per month.

Charcoal production is not only a profitable business idea from a financial point of view, but also a business idea that is good for nature. Its manufacturing technologies are constantly being improved. Thanks to the development of science and technology, it was possible to establish the production of an environmentally friendly product that does not harm the environment even when burned.

Charcoal became famous in ancient times, but became widely used only in the 20th century. Its popularity is explained by the presence of many advantages:

- environmental friendliness (charcoal is made from natural ingredients, absolutely harmless not only to humans, but also to nature);

- efficiency of use (actively releases energy during combustion);

- wide scope of application;

- versatility.

Charcoal is used not only in industrial production (for example, it acts as a reducing agent, purifies water and sugar, and allows air to be regenerated), but also in medicine and agriculture. Today, ordinary citizens are also showing high interest in this raw material. It is used to light fireplaces and prepare barbecue outdoors.

Due to the use of charcoal, the number of harmful emissions into the atmosphere has been significantly reduced, but the issue of the ecology of the planet is the most pressing today.

The highest demand for coal is confirmed by the constant improvement of its production technologies. The installations used are modernized, thereby increasing the quality of the product itself.

Varieties of charcoal

There are several varieties of charcoal. The amount of finished raw materials will depend on what kind of wood is used for its production. The size of the output is also affected by the correct application of the technology. For example, if oxygen enters a charcoal furnace, the original product may burn out completely.

The following types of charcoal are distinguished:

- black (softwood trees, such as linden or willow, are used to make it);

- white (on the contrary, it is made from hard wood, including oak and hornbeam);

- red (such coal can only be obtained from coniferous trees).

Production technology

The technology for producing charcoal is quite simple, but when producing the final product it is important to take into account all the nuances. Special skills and knowledge will prevent the yield percentage from decreasing to a minimum. With the right approach, the quality of the finished raw material also increases.

There are several technologies for making charcoal. But they all consist of the following stages:

- Drying. If you use wet raw materials, it will burn much slower.

- Pyrolysis. At this stage, the decomposition of raw materials occurs under the influence of high temperatures. It is important that no oxygen enters the oven during this time.

- Calcination. This step allows you to obtain high-quality coal without all kinds of impurities in the form of gases and resins.

- Cooling down.

Not so long ago, the production of charcoal was accompanied by harmful emissions into the atmosphere. But thanks to the creation of new technologies, we managed to avoid them. The coal production process is no longer accompanied by the release of harmful gases - they are used to maintain temperature in special furnaces.

Necessary equipment

You will need to purchase equipment for the production of charcoal. The total cost of the tools is about 350,000 rubles.

The production process begins with loading wood into a specialized chamber. It is equipped with special indicators that promptly signal combustion and drying. This means that enterprises must use charcoal kilns. Their number will depend on the industrial scale. It is customary to distinguish between stationary and mobile varieties. The second option allows you to process raw materials not in workshops, but at the wood collection site.

The ovens used differ in the number of chambers. If there is only one, then the newly produced coal is unloaded for subsequent cooling. With a larger number of chambers, cooling occurs directly in the charcoal kiln.

Furnaces with one chamber make it possible to obtain finished products from raw materials in a ratio of 1 to 7. The use of three-chamber furnaces can significantly improve this indicator.

Finally, the coal is crushed. This requires special crushers. The size of the finished product will depend on what it will subsequently be used for. Small pieces are useful in everyday life - when lighting your own fireplace or cooking meat in the grill. But industrial coal is larger in size.

When products of the required size are received, they are packaged in bags. Due to the lightness of charcoal, paper bags are usually used. For packaging, it is better to purchase a special packaging machine. Its cost can vary from 10,000 to 50,000 rubles.

Your own charcoal production business can bring up to 30 batches of finished products in one month. Their overall size will depend on the volume of the furnace.

The cost of the raw materials used in production is low, but the quality of the coal itself will depend on its quality. The most budget option is to purchase sawdust and production waste from furniture and paper factories. If an entrepreneur wants to get really high-quality products, then he should purchase:

- branch;

- branches;

- chopped firewood (but this option is the most expensive).

It is better to look for suppliers of raw materials among companies involved in wood processing. You can extract it yourself, but this method will be profitable if you open a large-scale production facility.

Sales channels

Charcoal production as a business is most promising if finished products are sold abroad. In Russia, the level of consumption is not as high as in European countries. There products are actively in demand not only in the industrial, but also in the domestic sense.

If coal production is small, then it will be easy to find consumers on the domestic market. It is better to focus on wholesale sales. Energy companies are constantly in need of raw materials. Coal can also be offered to private individuals who have large country houses with fireplaces, barbecue grills and barbecues. Additionally, you should pay attention to the following categories of possible clients:

- blacksmiths;

- smelters;

- companies involved in the production of medicines;

- large stores (regular grocery stores and those that specialize in selling goods for complete country and country holidays);

- catering establishments (kebabs, cafes, restaurants);

When producing coal, one must not forget that to some extent this product is considered seasonal. Especially if the main buyers are shops, catering outlets and ordinary people. When working with such a contingent, you can count on maximum profits in the period from May to October. But the rest of the time it’s worth trying to establish contacts with other potential buyers.

To attract as many consumers as possible, you need to take care not only of the quality of the products offered, but also of the recognition of your own brand. It is important to develop a logo and come up with an interesting name. It is also necessary to consider the design of the bags in which the coal will be sold. This way the consumer will know which product to buy next time.

If an entrepreneur wants to work with individuals directly, and not through store chains, then he can start selling products through social networks. To do this, it is enough to create your own page, display price lists, certificates and other mandatory documentation. This way you can maximize your profits.

Calculation of financial results

The level of profitability of coal production must be determined individually, since much will depend on the effectiveness of the chosen strategy. In itself, such a business is very promising and profitable.

The level of profitability of coal production must be determined individually, since much will depend on the effectiveness of the chosen strategy. In itself, such a business is very promising and profitable.

An important advantage of this area is the relatively low investment required to start your own business. If an entrepreneur plans to produce about 30 tons of finished products per month, then he will need 500,000 rubles. These costs will include:

- equipment (ovens, generators, packaging machine);

- equipment (shovels, chainsaws);

- raw materials;

- bags.

Monthly costs will include: purchase of raw materials, rent of premises, wages, advertising costs, transportation costs. In total, you will need 450,000 - 500,000 rubles.

For 1 kilogram of charcoal you can get about 20 rubles. When selling 30 tons, you can expect to receive an income of 600,000 rubles per month.

The profit level of a charcoal production business starts at 100,000 rubles. Such profitability will allow you to return the money invested in the business within 5-6 months after launch.

Let's sum it up

Charcoal production is a promising format for business. Despite the abundance of manufacturers of this product, the Russian market is not completely satisfied. Those entrepreneurs who have experience in the woodworking or forestry sector should take a closer look at the idea presented. This will not only allow you to quickly adapt to production conditions, but will also help reduce start-up and operating costs, while increasing profitability.

The efficiency of work will directly depend on compliance with production technologies. A negligent attitude can completely deprive an entrepreneur of profit.

Charcoal is considered a universal material. Its use is not limited to fuel production. Coal is widely used in construction as an insulation material, in agriculture as an additive and as an element in livestock feed.

Charcoal is successfully used in metallurgical production and the chemical industry. This material consists entirely of carbon, which makes it environmentally friendly and efficient. By all measures, the production of a product is a profitable undertaking that requires the use of special equipment and materials.

Types and areas of use

Before choosing equipment for the production of charcoal, you need to decide on the type of material that will be used in the process. There are three types of charcoal:

- white, obtained from ash, oak, acacia, birch (hardwood);

- black, obtained from willow, poplar, aspen, linden (softwood);

- red, made exclusively from coniferous wood.

The latter type is produced using a special method. Soft carbonization of the material occurs. During the process, the raw material is placed in a special oven, where it burns at a temperature of 355 0 C without air access. The raw materials burn, but not completely, forming coals.

In most cases, the black type is used for industrial activities.

The scope of application is quite wide. Raw materials are universal materials used in many industries:

- in the form of fertilizer in agriculture;

- as a material for smoke powder;

- as a raw material for the production of activated carbon used in medicine;

- as a reducing agent in industry;

- as a purifying material for water, gas emissions and wastewater from chemical plants;

- in the form of feed for livestock in livestock farming;

- for smelting rare metals;

- for the production of gas masks as a means of trapping poisonous gases;

- in the manufacture of electrodes;

- in the production of paints;

- for polishing printing parts;

- in the production of plastics;

- in the manufacture of resistances and contacts installed in electrical engineering;

- in glass production;

- as a building insulating material.

Equipment used

The production of charcoal requires the use of equipment:

- electrical energy generator;

- device for splitting firewood of hydraulic type;

- charcoal kiln;

- chainsaw;

- scales.

The main equipment for the production of charcoal is a charcoal kiln. It is a mechanism in which wood burns to form coals.

The peculiarity of the technology is the need to use a special pyrolysis oven. In the process of pyrolysis, carbon decomposes with a small amount of oxygen. In special charcoal kilns, pyrolysis technology is used, in which the wood burns out, but does not burn completely, turning into coal.

The minimum cost of such stoves is 20-100 thousand rubles. These prices apply to equipment that has already been used. New furnaces with high productivity will cost several times more. Their price reaches 2 million rubles. Modern models are capable of processing wood down to the formation of coal dust, which is in high demand in a number of production areas.

The cost of a standard electricity generator is 20 thousand rubles. The minimum price for a chainsaw and scales starts from 5 thousand rubles. The average cost of all equipment is 150-450 thousand rubles. The final price depends on the quality and performance of the equipment.

Coal production technology

For coal production, a special technology is provided, consisting of 4 stages:

- exposure of wood to fire under certain conditions (pyrolysis);

- calcination;

- cooling.

At the first stage, it is necessary to thoroughly dry the incoming raw materials. Damp wood does not smolder well. Before lighting it, a drying procedure is required. The raw materials are placed in a special block of the charcoal kiln. Flue gas heated to 150 0 C is supplied to it. The duration of the procedure depends on the humidity of the wood used. The higher its humidity, the longer it takes to process it with gas.

After drying, the moisture content of the raw materials should be minimal. For pyrolysis, which occurs at the second stage of coal production, raw materials with a maximum moisture content of 5% are suitable.

The pyrolysis process goes through several stages:

- the temperature in the oven increases to 300 0 C;

- at the specified value, the percentage of moisture in the raw material reaches zero, it actively absorbs heat;

- wood charring occurs;

- the charred material is exposed to elevated temperatures reaching 400 0 C;

- smoldering of raw materials occurs with active release of heat;

- when smoldering, the material becomes charcoal.

At the end of the pyrolysis process, raw materials with a high carbon content are obtained. Its level reaches 75%.

After pyrolysis, the resulting coal undergoes calcination. At this stage, the gases and resins contained in it are separated from the raw material.

At the final stage, the coal production technology involves its cooling. The procedure involves reducing the temperature inside the oven. Unloading coal from it is possible when the raw material does not spontaneously ignite when exposed to oxygen. The optimal temperature for coal with the possibility of unloading it is considered to be 40 0 C. Sometimes unloading begins already at 85 0 C.

Schemes for making charcoal at home

Three schemes for making it at home will help to significantly simplify the coal production process and avoid significant financial expenses on equipment:

- based on a wood stove;

- in a hole;

- using a barrel.

The first method is considered the simplest and has the lowest costs. It is not recommended to use this method in enclosed spaces. The production of charcoal requires the tightness of the equipment used and the absence of oxygen in the furnace. It is not recommended to stay indoors while wood is burning. It actively releases carbon dioxide, which is dangerous to humans, leading to poisoning.

Wood is placed in a conventional stove and set on fire. As soon as the wood burns, it is necessary to close the ash pit along with the doors. Thanks to this, conditions will be created inside the furnace similar to the conditions inside a specialized charcoal kiln. It takes about 15-20 minutes for the coal to smolder. The raw materials will need to be cooled.

Making coal in a pit is the most primitive, but useful method. If a number of conditions are met, it is possible to achieve a final product with good properties.

The procedure for making coal in a pit consists of the following steps:

- on an open plot of land, a cylindrical hole is dug 0.8 m wide and 0.5 m deep;

- the bottom of the pit is filled with a sand-clay mixture and carefully compacted to avoid mixing the raw materials with the ground;

- Material for ignition is laid out at the bottom of the pit, which can be small brushwood with birch bark;

- the first small portion of firewood without bark is added to the brushwood mixture;

- wood materials previously cleared of bark and chopped into pieces measuring 30 cm each are added to the firewood;

- a new portion of firewood is added to the burnt-out portion until the pit is filled to the very top;

- in the process of burning firewood, it is necessary to move it carefully, due to this the density of its fit increases;

- it takes about 1.5 hours to burn the wood, after which the pit will need to be sealed, covered with a layer of thick sheet metal that can stop the access of oxygen to the pit;

- cooling of the coal in the pit lasts several days;

- the finished raw materials are taken out of the pit, sifted and packaged.

Making coal in a barrel

This method is considered more advanced. The equipment used for it is a concrete barrel, on the bottom of which fire-resistant bricks are laid in a vertical position. Kindling material is laid between the bricks, and a metal grate is installed on top of them, on which chopped firewood is laid out.

As the firewood flares up, the top of the barrel is covered with a dense layer of sheet metal. Producing charcoal in this way requires the barrel used to be particularly sealed. Tight sealing is necessary when the smoke from burning wood acquires a bluish tint. The barrel remains in the closed position until it cools down.

At the last stage, the finished coal is taken out of the container, sorted and packaged.

Charcoal is a product obtained from the thermal decomposition of wood without access to air. The feedstock does not burn, but undergoes gasification under the influence of heat, thanks to which its structure is preserved, and the final product contains a large number of capillaries and pores. This quality is the reason for the widespread use of charcoal in various fields of human activity (it is an excellent adsorbent). It is used in the food industry, metallurgy, medicine, agriculture and other sectors. In addition, it is a biologically clean and environmentally friendly fuel. And the production of charcoal can bring good income.

Product Description

Charcoal is a unique high-carbon material obtained by dry distillation (charring) of wood. The raw materials for its production can be both coniferous and deciduous wood. The type of wood processed determines the type of final product. It is customary to distinguish three types of such coal:

- black - obtained from soft wood (aspen, linden, alder);

- red – a product of distillation of hard wood (oak, birch, etc.);

- white - made from coniferous wood (spruce, pine, etc.).

Firewood is considered the best source for producing coal. They produce a high quality product. However, it is allowed to use waste from the woodworking and forestry industries (branches, twigs, stumps), as well as waste from furniture production (trimming boards and planks) and even wood scrap (damaged and unusable pallets, boxes, etc.) as raw materials. It is useful to know why it is gaining more and more popularity among small businesses.

Important! Requirements for raw materials are determined by GOST 24260-80. Charcoal must be manufactured to meet the requirements GOST 7657-84. In accordance with this standard, the grade and belonging of coal to one of the grades is determined: A, B or C.

Charcoal is in great demand as a fuel. It is valued for its high heat transfer, the impossibility of spontaneous combustion, and the absence of harmful substances. Such a product does not emit smoke or open flame during combustion. Therefore, it is often used for grills, barbecues, open fires, stoves, and fireplaces.

This material is used to disinfect industrial wastewater and air emissions from factories and enterprises. It is used as a reducing agent in non-ferrous and ferrous metallurgy. Charcoal has also found its use in animal husbandry and crop production: it is added to the feed base for birds and livestock, and it is used to fertilize the top layer of soil. It does an excellent job of removing unpleasant odors and is suitable for regenerating water and air in enclosed spaces.

In addition, during the decay of wood, by-products are formed - resins, which can later be used to make acetic acid, turpentine, methyl alcohol, etc.

All this suggests that charcoal production as a business is a very promising area. Next we will talk about what an entrepreneur will need to master it.

The World of Business website team recommends that all readers take the Lazy Investor Course, where you will learn how to put things in order in your personal finances and learn how to earn passive income. No enticements, only high-quality information from a practicing investor (from real estate to cryptocurrency). The first week of training is free! Registration for a free week of training

Technology and equipment

The production is based on the process of thermal pyrolysis - the decomposition of organic compounds in the absence or limitation of oxygen. Until recently, the installations used to ensure this process caused significant harm to the environment by releasing the resulting gases into the atmosphere.

Modern technologies are based on the use of retort-type charcoal kilns for the production of charcoal. Such furnaces solve the problem of pollution; moreover, they allow the use of gases formed during the pyrolysis process to maintain the required temperature, thereby reducing the entrepreneur’s energy costs and ensuring a continuous production cycle.

Raw materials are loaded into removable retorts (closed containers), which are placed on top of the combustion chamber. In these containers, wood decomposes under the influence of heat (temperature is 400–500 ° C). At the same time, in the oven, the raw materials are dried in the upper part, the wood is heated in the next retort, the wood is decomposed and the coal is calcined in the middle part, and the finished product is cooled in the lower part.

The vapor-gas mixture formed in this case is discharged through special pipes, after which the gas is separated from the liquid in a condensation device.

Equipment for the production of charcoal can be either stationary or mobile.

If your budget allows, you can immediately buy an expensive and high-performance installation. For example, you can purchase a frontal two-retort Russian furnace PF2RG-60 “Standard” with a capacity of up to 120 tons of finished products per month. Its price is approximately 2.5 million rubles.

Such an installation will also make it possible to effectively use excess heat and energy from pyrolysis gases. To service it, only one employee and a loader for carrying retorts with a lifting capacity of 5 tons are required. Any piece of waste can be used as raw material.

It’s easier and cheaper to purchase a small-volume installation, consisting of a chamber with a built-in boiler and equipped with afterburning of pyrolysis gases, for example, the Zarya charcoal kiln. It has a simple design, does not require electricity, and is suitable for installation in logging areas.

In one cycle, such a plant can produce up to 5 tons of high-quality coal (the number of cycles per month is from 7 to 16). Its cost varies from 480 thousand to 1,180 thousand rubles, depending on the modification. Mobile pyrolysis plants of small volume, producing up to 8 tons of products per month, cost from 100 thousand to 360 thousand rubles.

The cheapest and simplest option for producing charcoal, which you can try even at home, is to use an ordinary two-hundred-liter metal barrel for this purpose. A description of the method and a diagram according to which you can design a stove yourself are in the following video:

Of course, this method will not bring a lot of money. It is more suitable for those entrepreneurs who run their own cafes and kebab shops and need regular supplies of charcoal for cooking (see). Those who plan to produce coal for sale should consider the more productive options discussed above.

In addition to the basic equipment, you will need a device for chopping wood, hand tools (axes, hacksaws), a chainsaw, scales and a packaging machine. According to the most conservative estimates, it will take about 800 thousand rubles to launch a mini-production.

Business Starting Plan

Before you start implementing an idea, you need to prepare a project. It is advisable to start with market research. You need to outline the circle of potential clients, determine the existing level of supply, and analyze your capabilities.

An important step in organizing such a business is searching for suppliers of raw materials. Ideally, if the production is located near logging or wood processing enterprises. The further away from the sources of raw materials, the higher the transportation costs and the cost of finished products.

The business plan for charcoal production must include calculations of capital and operating costs, as well as a forecast of income and profit. One-time start-up costs include costs for preparing the territory, purchasing, delivering and launching equipment, processing documents, holding promotional events, etc.

Important! You can register such a business as a . Code for the type of main business activity according to OKVED, which must be indicated when registering a charcoal production business – 20.14« Production of other basic organic chemicals» .

In small production (up to 15 tons per month), the cost of a ton of charcoal is approximately 20 thousand rubles. The average price for finished products is 25 thousand rubles per ton. Thus, by producing 15 tons of charcoal per month, you can receive about 75 thousand rubles of net profit.

It's useful to read about. Legal aspects, selection of premises, purchase of equipment and search for personnel.