In-demand metal products. Profitable business in the garage: the idea of producing metal products! How to build your business selling metal products

Nowadays you can’t do without metal products. They are used in different areas of life. For example, banking institutions cannot operate without them. Due to the fact that the work of financial institutions and banks is associated with very high risks, they cannot do without security equipment made of metal. Metal safes are in demand, in which you can store both money and important documents. Fireproof safes are available for sale. Also today there is a demand for depositories and metal cashier trays.

Metal fences and fences are in demand among the population. They are in demand mainly by cottage owners, gardening partnerships and summer residents. The peak of sales occurs in the spring-summer, when many begin construction. Such fences provide protection for a flower bed, lawn, garden plot or site. They do not create a feeling of enclosed space, as they have a lattice design. Metal peak fences up to two meters high are popular. Metal fences are not afraid of corrosion, precipitation, wind and mechanical damage. In addition, they are inexpensive to operate (photo 1).

There is also a demand today for metal products that are used in the construction industry - pipes, fittings, metal sheets, curbs, poles. There is a demand for corrugated sheeting, which is made from metal sheets. It is used for organizing fences and as a roofing material. It does not rot, does not corrode, and does not need to be painted periodically. Thanks to the latest technologies, it retains its color for a long time (photo 2).

Metal doors are also popular. They protect well from intruders. In addition, a metal door has excellent sound insulation properties and prevents cold from penetrating into the room. People are often interested in bulletproof and fire-resistant doors. Although they are expensive, city dwellers prefer them. Therefore, the production of metal products, in particular metal doors, is a very profitable and profitable business (photo 3).

The population also buys metal racks of different shapes and sizes. The demand is mainly for retail, warehouse, archival and office shelving made of metal. Such racks are purchased less often for the home. In turn, retail racks can be universal, for hypermarkets, trading floors and display, and for a warehouse - cantilever, shelf, cargo and for long cargo. In the office, such racks are purchased to store books, documents, folders, and catalogs. Archival racks can be mobile (photo 4).

Metal furniture is in demand. Such furniture has a long service life. It can be disassembled and reassembled many times without losing its quality and functionality. In addition, metal furniture contains no volatile resins, is water-resistant and easy to use. Most often people buy metal cabinets. Today, such cabinets have become an integral attribute of offices and organizations. There are file cabinets, office cabinets, archive cabinets, filing cabinets, and deposit cabinets. They are made of steel. There are different colors. Office cabinets vary in design. They are durable and designed for storing business information, material assets, and folders. There are also wardrobes. They have a special hole for ventilation, as well as a lock that will protect things from theft. Accounting cabinets are also made from metal. These seem to be durable and lightweight structures (photo 5).

Working with metal is the calling of real professionals. But you can make money without your own workshop if you buy the Metal Master franchise. Real income at the start can be up to 100,000 rubles, which in 2-3 months will allow you to get into the black.

Aesthetics and comfort are words that every second resident of Russia inevitably associates with their home. People are equipping their homes and garden plots: creating recreation areas with barbecues and gazebos, creating unique landscape and interior design, purchasing swings for children and comfortable benches for the veranda and yard. The result is a turnover of millions of rubles per year, a significant share of which can become yours if you decide to purchase the Metal Master franchise.

Metal products: practical and attractive

The original patterns of metal forging fascinate and force many owners of private houses to leaf through catalogs for a long time and look at numerous benches, swings for children and adults, gazebos and fences with fancy patterns. Products made of metal and wood are in high demand - they are purchased by:

Metal products are also widely used in the ritual sphere - as fences for graves and for arranging areas for remembering loved ones.

Taking into account potential buyers and the requirements for the installation conditions of metal products, the business can safely be called in demand and all-season.

How to build your business selling metal products

Beginners often imagine business as something large-scale and requiring huge investments. Production shops, specialists in working with rolled metal and welders, a huge sales department and warehouses - if you think in this way, then you will devote your whole life to collecting start-up capital and finding investors.

"Metal Master" offers you simple start conditions with minimal investment:

- you do not need to hire staff - one person is enough to manage the advertising company and process incoming applications;

- huge warehouses can easily be replaced by a colorful online store with a large catalog of metal products;

- production will be carried out by experienced Metal Master craftsmen;

- You can purchase goods to order, by prior agreement with the client and even receive an advance payment from him, and delivery will be carried out by any transport company - quickly and reliably.

To open a profitable business that has not lost its relevance for decades, you will need a computer with Internet access, several hours to process incoming applications and a small starting capital of 200-300 thousand. It would also be useful to rent a small office-warehouse with an area of 15 m2, where you can store the arrived goods until settlement with the client.

Preliminary calculation of business profitability

"Metal Master" is a manufacturer that strives to maintain affordable prices and regulate pricing policy. When starting cooperation, you can be sure that the offer will be one of the most profitable in your region. An impressive catalog of products - from grave fences to stylish upholstered furniture - will help you attract the maximum number of buyers.

- With active promotion of the store, advertising on social networks, in the city and on trading platforms, you can attract more than 60 customers per month, even in a small town.

- The average purchase price will be 5-7 thousand rubles.

- Revenue per month will be at least 300,000 rubles, of which 30-37% is net profit.

- Don't forget to deduct taxes and office rental costs. The company's royalty is only 2.5%, which is easy to pay off monthly.

The minimum profitability at the start is about 100,000 rubles, so you can recoup the cost of the franchise and become a plus in 2-3 months.

A significant advantage of opening a business under the Metal Master franchise is the quick start-up. An online store and a set of presentation and advertising materials are provided, thanks to which it will be easy for you to express yourself and attract your first clients.

The business will be attractive to craftsmen who have already established their own production and want to expand and improve it. So, you can assemble and install swings, gazebos and benches, add new products to your assortment and significantly increase the profit of your company.

Free swimming vs cooperation with Metal-Master

By putting into practice a simple model for selling metal and wood products through an online store, you can open your own business without purchasing a franchise. But you must be prepared for the difficulties that Metal-Master has already overcome.

- You have to find responsible suppliers and negotiate with them on the supply of materials or finished products at a low price.

- Since each company has minimum purchase thresholds, you will have to rent at least a small warehouse space.

- Word of mouth, the leading sales tool in the regions, may not work in your favor. If you agree on the delivery of goods and take an advance payment from the client, but the company delays shipment or refers to the need to wait for consumables, then you will not only have to wait, but also make excuses to the client.

- You will need to analyze demand and come up with a line of “hits”, as well as test all advertising methods and, only after spending money, find out about their effectiveness.

Today, I want to talk about an option for making money at home - making souvenirs from scrap metal.

This type of activity does not require large investments or special professional skills. Also, for this type of activity you do not need special production premises; work can be organized in a garage or barn.

We will talk about figurines made of bolts, nuts and wire. These funny figures look original and are quite popular among buyers. Also, an undeniable advantage of such production is that the figurines are not made according to templates. The flight of fancy is not limited here. There are no restrictions on size or shape.

For mass sale, figurines are made no more than 10–15 centimeters in height. They are kept small due to the marketing policy of souvenir shops. Small products sell much better and are reasonably priced.

But let’s move on directly to the production itself and the necessary equipment.

Costs of organizing production

For production you will need a small room. Ideally, you can use a garage or other utility room in which you can place equipment and inventory.

The area can be from 6 square meters. The main requirements for the room will be: its normal illumination, good ventilation, the presence of protected sockets for connecting electrical equipment, convenient wall shelves.

Special attention is needed pay attention to fire safety of the premises, since welding will be used during the work.

Of the necessary equipment, the main unit will be an inverter-type semi-automatic welding machine. This is the most expensive part of the investment. It can be purchased either new or used. There is no fundamental difference, as long as the unit works properly. For a beginner, the best option would be to purchase a new device. We will use it for production planning. This device has all the necessary functions and is affordable.

Equipment and inventory

Inverter type welding machine, RESANTA SAIPA-135 – 12,800 rubles.

Carbon dioxide cylinder, volume 20 liters - 1,700 rubles.

Pressure gauge for a cylinder - 1100 rubles.

Oxygen hoses – 100 rubles per linear meter.

Welding mask “Chameleon” – 1800 rubles.

Grinder for 125 mm disc. – 1400 rubles.

Screwdriver – 2500 rubles.

Metal table, size 1 meter by 1.5, – 1500 rubles.

Vice – 3000 rubles.

Screw clamps, 2 pcs. - 500 rubles.

Other necessary tools – 1000 rubles.

The amount for organizing production from scratch will be 28,150 rubles, at prices as of May 2018. But this is the maximum amount, and it is calculated exclusively for the purchase of new equipment.

You can purchase all this on the secondary market, and the cost of purchases will drop by half. In my case, the cost amounted to 13,700 rubles.

I bought the welding machine assembled, with a cylinder, hoses, and a mask, for only 7,200 rubles, and I got a screwdriver with a small grinder for 2,500. Here it’s a personal matter for everyone, which tool to use - new or old.

With an old tool, it is easier to start a business if you focus on minimal investment. The old tool can later be replaced with a new one. That's what I did. I started with the old one, and then gradually replaced it with the new one.

More about material costs

To make the first batch you will need raw materials and consumables.

Supplies you will need:

A roll of welding wire – 650 rubles.

Grinder discs, 6 pcs. – 150 rubles.

Refilling a cylinder with carbon dioxide costs 350 rubles.

Grinding wheel – 250 rubles.

Nozzles for cleaning rust, soft, 2 pcs – 350 rubles.

Metal brushes, 3 pcs. – 180 rubles.

Rust converter, 2 liters – 200 rubles.

Solvent, 20 liters – 700 rubles.

Paint, 4 cylinders – 750 rubles.

Metal varnish, 2 bottles – 300 rubles.

Brushes – 150 rubles.

Work gloves, 5 pairs – 75 rubles.

The amount of expenses for consumables is 4159 rubles. These materials are enough to produce at least 90 products, and this amount will be included in the calculation of the cost of the product.

Also, raw materials are needed for production. There are no barriers here. To make figurines, raw materials can be taken from metal scrap yards, car repair shops and auto repair shops.

If, nearby, there is some enterprise where I repair mechanical units, then the raw materials can be taken there.

For example, I get raw materials from a company that repairs transformers and substations. They sell me the necessary metal to choose from, at the price of scrap metal, 10 rubles per kilogram.

I choose what I need for the figurines, and these are mainly nuts of sizes 6, 8, 10, 12, wire with a diameter of 2 -3 mm, bolts of sizes 5, 6, 8, 10, pieces of metal 0.8 mm thick., bearing balls, springs.

Small bearings look very good as wheels. I buy them, and other little things, from auto electricians, also at the price of scrap metal.

In terms of cash costs, such a purchase costs approximately 1,500 – 2,000 rubles. I take 150 -200 kilograms of raw material, and this is enough for me to work for two months.

Production profitability

The profitability of this production is high. Let me give you an example of a calculation.

The amount of expenses for consumables is 4159 rubles.

These materials are enough to produce an average of 90 figurines.

For 90 figurines you need to use 40 kilograms of raw iron, which costs another 400 rubles.

(2775 +400)/90=50 rubles. This is the raw material cost of one figurine.

To this amount we add another 15 rubles, electricity costs, and we get 65 rubles. 65 rubles, it costs one figurine to make.

The selling price of one piece is from 300 rubles. The price of the figurine depends on the imagination of the author.

If you depict just a man on it, then its price will be 300 rubles, and if you make a composition, then the cost will increase to 700 - 800 rubles. The cost of some products reaches 3000 rubles.

I try to make 2 – 3 items a day. When I learned this, I simply made robot figures, and they were sold for 200–300 rubles, but later my skill grew, and I began to make real masterpieces.

For example, a stand for business cards with an image of an office robot - a worker - sold for 2,500 rubles.

So, if you produce 50 products per month and sell them for 300 rubles, then the profit will be 11,300 rubles. But producing 50 pieces a month is not difficult, and the price of 300 rubles is not the limit. The average monthly income for the production of 90 products is from 30,000 rubles.

Here it depends on the individual person. If you try and find sales for your products, and this is not difficult to do, then production can be increased significantly, and this will already become a good income.

This business is not seasonal and production can be maintained throughout the year. To do this, of course, you will need to open an individual entrepreneur so that you can enter into agreements with stores and points of sale of souvenirs, but these are details.

About production

The production process itself should be divided into several stages. First you need to sort all the elements from each other.

Nuts, bolts, balls, springs and pieces of metal are distributed into different containers, and then filled with a solvent mixed with a rust converter.

All the metal is in this liquid for one day. Then, all this is removed, dried, and cleaned with a wire brush. You can do this yourself, but I try to hire someone from outside to do this.

For such services I pay 10 rubles for each cleaned kilogram. A hired employee, he works once a month, which takes him almost two full days. He receives from 2000 to 3000 rubles for this.

This suits me, as well as my neighbor, who is happy to do any part-time work; I attract him for these purposes.

Once the material has been cleaned and sorted, the creative process begins. First you need to think about the theme of the figurines.

For example, it’s spring, and the fishing season is in full swing, therefore, the entire party will be dedicated to the theme of fishing.

By the New Year, figurines of snowmen or hares under the Christmas tree will be in demand.

In the summer, robotic swimmers and divers sell well.

Robots that pick mushrooms are sold in the fall. Seasonality in sales of souvenir products should be observed.

Stands for salt and pepper shakers, stands for pens, business card holders are in demand all year round. The same is true with robot motorcyclists.

That is, at this stage you need to decide on the compositions. This is necessary in order to start cutting workpieces.

The robots' arms and legs are made of wire. If, for example, you need robots that play football, then the wire is cut according to one template, and if you need robots that play fish, then these are slightly different sizes.

Also, depending on the composition, platforms and additional parts for the figurines are cut.

This process takes approximately two to three days. Next, all the parts are laid out in containers, and the next stage begins - welding of the products.

If anyone thinks that for this production you need to be an extra-class welder, then they are mistaken. There is no need to weld the pipes through which water flows. This is not welding a ship's hull. This is a simple spot tack welding. You can learn how to use the device in one to two days; fortunately, there are a lot of materials on the Internet about how to do this. I learned this in one day.

The welding process occurs as follows - first the figures are made, and after that a composition is made from them. It all depends on your mood and imagination. The uniqueness of such souvenirs is that not one figurine is similar to the other. They are just like people - they all seem to be the same, but at the same time, they are all different.

If you are not in the mood to work, then the figures will turn out appropriately, and, conversely, if you are in a good mood, the figures will simply shine. It takes a week to weld the figures if you do it 2-3 hours a day.

When all the components are ready individually, the next step is to make compositions from them. Here too, the main assistant is fantasy. Compositions can be made up of one, two, or even more figures. This process takes approximately a week.

When the products are welded, you need to start cleaning and painting them. First, all welding seams and welding stains are cleaned. This work is done with a grinding wheel.

Next, when the seams are cleaned, the figurines are processed with a soft nozzle. At this stage you need to get shine on the figures. This stage is very important, since if rust remains on the product, this may lead to peeling of the paint in the future.

Cleaning with a soft wire nozzle is done using a screwdriver. You should not use a grinder for this purpose. This may result in personal injury and product damage.

After cleaning, you need to move on to painting the products.

I use two colors to paint my products – gold and silver. I simply varnish some of the products and leave them in their original metallic colors.

Products should be painted in two stages. First, the bottom of the figurines is painted, and then the top. To avoid mixing colors, you need to paint in small batches. The optimal quantity for painting is 20 pieces.

The products are ready, and the next step is to sell them.

Sales

There are several proven paths, and several original ones.

Of the proven ways, it should be noted the sale through online trading platforms. They work well, and I sell almost half of my products through them.

Stores take a percentage of sales. They sell goods well, but the problem with such trade is that the stores have many types of souvenir products, and it is profitable for them to sell what they earn more from. If you give them a normal wholesale price, then with the store markup the cost of the product turns out to be, to put it mildly, overpriced.

For this reason, the goods may remain in the store. If you give stores a lower price, the profitability of the business decreases, but the goods are sold faster. With stores you need to look for a middle ground, and work with them only if the product is not selling well through ads.

Another way of implementation is to sell figurines through your own outlet. To organize it, you need a trade tent, a table, a chair, preferably everything folding, and a permit for outbound trade.

The point should not be open every day, only on weekends. People should get used to the fact that every Saturday and Sunday you can buy handmade souvenirs in this place. They must see the product and be able to touch it with their hands.

An original solution is to make custom souvenirs. Many people want the figurine to look like the person to whom it will be given.

For example, some clients wanted to give an original gift to a businessman they knew. He doesn’t need money, and they didn’t know how to please him, until they came across a figurine made by me.

They found me and asked me to make a souvenir. The condition was that the figurine should reflect the appearance of their friend as much as possible. The task was not easy, but I did it.

I made the figure a larger nose and protruding ears, like the hero of the occasion. The clients were very satisfied. The cost of the figurine was 7,500 rubles. True, I had to give it to processing with galvanic copper, and it cost me 1,500 rubles, but at the same time, I received 5,500 net profit for this work. Now I can do this kind of metal processing myself, but then I didn’t have it.

About business development prospects

For those who want to put this type of business on stream, I would advise them to do the following - conquer the markets of southern resort cities.

So far there are few of these products there. These products will be well received if compositions of the appropriate theme are made. It must be palm trees, shells and anything that will resemble the sea.

A very good idea would be to put the names of cities and years on souvenirs, for example “Sochi 2018”. Such products will sell very well during the holiday season, and sellers will be happy to buy it.

True, for such trade, you need to completely change the production concept. Raw materials will no longer need to be purchased from metal receiving yards, but directly from metal product manufacturers.

Line production should not be idle due to a lack of material, so you will have to purchase everything new. This, of course, will significantly increase the cost of production, but here you can make up for it in sales volumes.

Also, such production will require expansion of staff and the purchase of additional equipment. We need to prepare responsibly for such a step so that people always have employment.

For such production, you will need a reserve of free money that can support the operation of the enterprise in the event of a partial or complete lack of orders.

The development of such a business is possible only with sufficient funding and the right marketing policy.

In the modern world it is so large that it is difficult to find an industry in which they are not used. Metal structures are the basis of any industrial production and are often in demand in agricultural areas.

The production association Remstoymash LLC, located in the city of Kurgan, has extensive experience in the production of metal structures of any complexity. The organization began its activities in 68 of the last century. The specialists of the association know very well what kind of metal structures there are, their purpose and application.

The company produces a wide range of metal structures that are in demand. These include:

- Prefabricated metal structures of low weight;

- Non-standard metal structures;

- Equipment for gas stations and gas stations;

- Various types of industrial equipment.

The most popular metal structures and the advantages of their use

With all the variety of metal products, it should be noted which metal structures are in demand. Practical steel profiles have become the undoubted leaders. They are the basis for the construction of all construction projects for any purpose. These could be warehouse complexes, residential buildings or industrial enterprises.

When using metal structures in construction, the cost of constructed objects is approximately 30% cheaper than using other materials. In this case, construction time is also significantly reduced.

The high loads to which large structures are subjected require the use of more powerful steel structures. Accordingly, the demand for time-tested metal elements produced by classical methods does not fall. These can be columns, I-beams and reinforced channels, made by welding, stamping or casting. These powerful elements form the basis of structures to which lighter structures are attached and supported.

High-quality metal structures are suitable for both standard projects and non-standard orders. When used, the structure is provided with a high degree of reliability. Steel structures assembled directly at the construction site are easy to transport. They do not require special equipment to transport them, and they do not take up much space. At the construction site, assembling metal structures does not require much time; they are easy to install.

Types of metal structures and their purpose

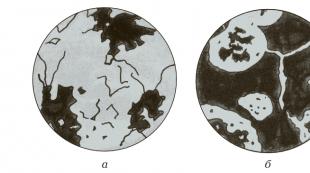

To ensure exact matching of parts during installation, special equipment is used during their manufacture. Frames and metal structures used in construction are made from steel or rolled steel. The introduction of modern production technologies contributed to the production of a wide range of standard assembly kits.

When ordering products in this form, the time for design and construction work is significantly reduced, and approval procedures with RosTechNadzor authorities are simplified.

In addition to those metal structures that are most often in demand, the production association is engaged in the manufacture of capacitive and reservoir equipment. Such equipment can also be made according to standard or individual orders. Metal structures of this type have been developed and used mainly in the oil and gas and petrochemical industries.

In addition, capacitive equipment is used in other areas, these can be:

- Drainage systems;

- Containers for various liquids;

- Capacitive devices of any shape;

- Receivers;

- Various tanks.

The structures have single-wall and double-wall buildings. Depending on the purpose, the necessary coating is applied. Depending on the type of installation, they can be installed vertically or horizontally.

Heat exchange equipment has also become in demand today in various industries. This type of device is also manufactured at the production association Remstoymash LLC. The high quality of heat exchangers produced at the enterprise guarantees good performance throughout their entire service life.

The company's engineers have developed original circuits for filtering equipment that is produced at the enterprise. They allow you to capture solid inclusions with a size of 0.2 microns. In addition to the production of filters for liquids, the association has established the production of filter systems for gas purification.

High-quality management and the introduction of innovative technologies into production processes allow the association to maintain selling prices for its products at a low level. Factory production lines are systematically modernized without stopping work processes.

The new technologies being introduced make it possible to produce high-quality products that meet all necessary requirements and reduce production time.

You may be interested in:

A fire tank is a place to store a supply of water to extinguish a possible fire. It must meet the design requirements specified in SNiP 2.04.01-85 Internal water supply and sewerage of buildings P.6. This facility must, in accordance with the above norm, be built on the territory of an industrial enterprise. To create a fire reserve of water, artificial and natural reservoirs can be used...

An oil and gas separator is a device in which oil is separated from associated gas (or water is separated from oil) due to different densities of liquids. There are horizontal, vertical and hydrocyclone separators. The main areas of application of oil separators: petrochemical, oil refining and other areas where separation of oil emulsions is required. Operating principle of oil separator Oil separation process...

To control the flow of liquids and gases in pipeline systems, their lines and sections, special devices called shut-off and control valves are used. This type of pipeline fittings is designed to completely shut off or regulate the pressure of the medium flow, controlling other technological processes, which include: fluid pressure; pressure; temperature; volume of transported substance. For...

Technological processes of synthesis and decomposition into fractions of complex substances are based on the use of endothermic and exothermic reactions. Heat redistribution in a closed loop is the operating principle of the installation. Heat exchangers in the chemical industry are the main equipment, along with reactors and distillation columns. In the food industry, sterilization and disinfection of products occurs when...

Enterprising people are planning to open their own business. After all, financial freedom means independence, stability and confidence in the future. But opening your own business is not so easy; you need to clearly understand what difficulties you will have to face and have certain knowledge. Today, there are many business ideas that allow you to make money in various market segments. The production of various metal products (badges, signs, wardrobes) fencing or fences is one of the promising areas of small business.

Business ideas for metal production:

1. Metal fences and barriers are a profitable business segment, suitable for both large cities and small towns. Fences and fences are in demand by summer residents, gardening partnerships, and cottage owners. The advantage of this type of business is that you can work directly with customers. Metal fences and enclosures are especially in great demand in the summer and spring, that is, during the construction start season.

To start production, you need to have special tools: a welding machine, an angle grinder, a hammer drill. You can buy them or rent them for the first time. If a decision was made to purchase a tool, then this expense item would be about 120 thousand rubles.

Advice! You can’t do this kind of work on your own, so you need to hire additional personnel: a welder and a mason. Then, as production develops, the number of workers will need to be increased. The workers' salaries will depend on the work performed, thus their activities can be motivated.

You should definitely pay attention to advertising so that orders are constant and not periodic. Not only online resources are suitable for advertising, but also printed publications: newspapers and specialized magazines. Business income will be about 30 thousand rubles per month.

2. A profitable and promising business is the production of metal doors. The demand for metal doors is constantly growing. Competition in this market segment is quite high, but by offering high-quality products made on modern, expensive equipment, you can count on a consistently high income.

Before starting a door manufacturing activity, you must obtain a license to permit construction activities. To accommodate the equipment, you will need a room of at least 300 m2, with two compartments. In the first, doors are made, in the second, the finished product is painted.

For the production of doors, former production workshops are suitable, which are best rented not within the city, but outside it. Thus, you can significantly save on rent, which will cost up to 17 thousand rubles. At first, you can use two garages next to each other as production workshops. But this is only temporary production; in such conditions it is impossible to organize mass production of high-quality products.

What kind of doors should I make? Expensive or cheap? The entrepreneur must decide for himself. Of course, if there is enough capital at the first stage, it may make sense to produce “elite class” doors. Since for the profitable production of cheap doors, it is necessary to produce and sell about 250-300 units per month.

3. The production of metal badges is one of the types of home business that does not require huge production areas. The main thing is to approach the issue wisely and develop a client base. Since the demand for badges is not very high, there is little competition in this segment. Before starting the production of souvenirs (badges or medals), it is necessary to take into account a number of nuances of this business:

- You can’t do this on your own, without knowledge of metal processing. There are two options: either study the entire manufacturing and processing process yourself, or hire a specialist;

- It is better to sell manufactured products in bulk, in large quantities;

- For the development and prosperity of a business, it is necessary to increase sales markets by offering original products and made from high-quality materials.

Expensive equipment for this type of business is not required, it is enough to have:

- Printer;

- press;

- laser engraving machine;

- stamping equipment.

Such a set of equipment will cost approximately 300 thousand rubles. To produce higher-quality products, it is necessary to use a polishing or sandblasting machine, this will increase the cost item by 20 thousand rubles.

4. Production of metal signs for external and internal use. Entering the market with the desire to make signs is not enough. For a successful business and demand for products, an entrepreneur must offer a bright, original idea, while strictly observing formalities. An original sign is a success and an advertisement for the master. A metal plate must not only be original, but the text must be legible and easy to read. In order to familiarize potential customers with finished products, it is best to create a catalog. In such a catalog you can place photographs of finished products, and on separate pages you can demonstrate the original inscriptions on the plates.

Small production can be located directly in an apartment or garage. There are many technologies for making signs. The choice will depend on the knowledge and qualifications of the craftsman, as well as production conditions.

You can start making signs as an additional income, and if business goes well and the clientele expands, you can draw up documents and work as an individual entrepreneur. Then it makes sense to expand production, hire craftsmen, and an experienced accountant to account for expenses and income of the activity.

Finding clients will not be difficult. To do this, you need to create your own website on the Internet and send targeted advertising to companies. If this is not possible, then use the directory of organizations and, through phone calls, build up your client base.

This type of business requires patience and hard work. You won’t be able to get results right away; only after 4-5 months will the business be able to become profitable and successful.