Business sale of animal feed. How to make money in the production of animal feed. Selection of premises and equipment

After the introduction of sanctions against our country, the issue of food security arose. Small businesses should help the state with this. That is why farms and private farmsteads have now begun to actively develop. The question arose about food, what to feed? The feed industry began to develop. The need for quality feed has increased sharply.

Starting a business selling feedAn opportunity arose to organize a business idea for selling compound feed. Before going to the tax office and registering an individual entrepreneur or LLC, you need to draw up a business plan.

Get to know the market

It is necessary to conduct an audit of the sales market. Find out your future competitors and conduct a little marketing on which feed is more in demand.

Talk to farms and private farmsteads and offer cooperation. You need to find one or two farmers with whom you will enter into an agreement for the supply of feed. Do not neglect zoos, nurseries of wild and domestic animals. Drive through feed mills, there are quite a lot of them, and agree on the supply of the required feed in the required quantities.

It is easier to negotiate with small feed mills. They are also entering the market and they need sales and advertising, which you will provide. You can play on this. It is advisable to purchase feed with deferred payment or with payments after the sale of products.

Composition of average statistical feed

Recipe for complete feed for broiler chickens in poultry farms.

| Diet components | Growing period of broiler chickens | |||

| 1-28 days | 29 – 56 days | |||

| % | G | % | G | |

| 1 | 2 | 3 | 4 | 5 |

| Barley | 25 | 22,5 | 28 | 36,4 |

| Corn | 25 | 22,5 | 25 | 32,5 |

| Wheat | 15 | 13,5 | 18,6 | 24,18 |

| Sunflower cake | 23,4 | 21,0 | 19 | 24,7 |

| Fish meal | 8 | 7,2 | 5 | 6,5 |

| Meat and bone meal | 0,5 | 0,45 | 2,5 | 3,25 |

| Herbal flour | 1,6 | 1,44 | 1 | 1,3 |

| Chalk | 1,2 | 1,08 | 0,5 | 0,65 |

| Table salt | 0,3 | 0,27 | 0,4 | 0,52 |

| TOTAL | 100 | 90 | 100 | 130 |

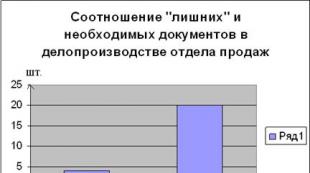

First month expenses figures

What did you buy?

| volume | |

| laying hen start PK-2 (baby) | 100 |

| laying hen height PK-4 (crumb) | 100 |

| laying hen productive period PC-1 (pellet) | 200 |

| laying hen productive period PC-1 (crumbs) | 200 |

| food for rabbits PK-90 (with grass meal) | 300 |

| food for rabbits PK-90 (without grass meal) | 0 |

| start for broilers BR-1 | 300 |

| growth for broilers BR-2 | 300 |

| finish for broilers BR-3 | 100 |

| feed mixture (crumbs) | 100 |

| hen quail (crumb) | 200 |

| growth for calves KK-63 (from 4 months) | 0 |

| duck start PK-21 (crumb) | 300 |

| height for ducks PK-22 (crumb) | 300 |

| Total: | 2500 |

Warehouse space

We are looking for a place for a warehouse, taking into account that the feed is stored in a dry room and its shelf life is limited to 3 months. When these conditions are met, you can think about legal ownership.

Starting a business

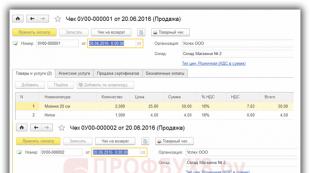

Starting a business And so you decided to implement the business idea of selling compound feed. You rented a warehouse space, signed contracts for the supply and release of products, and you start working. We take into account that at first the profit from the sale of compound feed will be minimal. Sales are not established, deliveries are not regular, payment is delayed.

It is necessary to conduct an advertising campaign. First of all, using available means, you place information on the sale of mixed feed on the Internet, taking into account that the range of products sold is varied. You need to travel through nearby villages and try to convince farmers to purchase feed from you, offering additional conditions for delivery or payment for the goods. We take into account the seasonality of sales.

Chickens and young animals

In the spring and the first month of summer, most often they will buy feed for chickens and young animals. Next for grown animals. The warehouse should always have an assortment for raising poultry, rabbits, cattle and, of course, pigs. Pig farming in private farmsteads is in a deplorable state and this is due to the African swine fever epidemic.

When implementing the business idea of selling compound feed, you should not forget about pets, cats and dogs. You can earn some good money here. Especially if you organize feed delivery directly to customers.

The economic component here can be much higher, since the competition here is not much less than in the sale of compound feed for farm animals. The ever-growing pet market is opening up new perspectives.

The relevance of this area of production is justified by the intensive development of agriculture and the need for animals, birds and fish to receive a balanced diet. This increases their life expectancy and ensures health. The quality of the resulting product also depends on the correct diet, so buyers of combined feed regularly need inexpensive but complete feed.

Compound feed (combined feed) is a food product for feeding animals and birds, which includes a variety of grain raw materials, grass, fish or chalk, salt and other microadditives that provide complete nutrition, rich in protein, vitamins and microelements.

Product range

Combined feeds are produced according to different recipes for each type of animal and poultry, taking into account their age and purpose ( milk, wool, feathers, meat, fat, leather, eggs, caviar).

Types of feed according to nutritional value:

- concentrated feed (high content of protein, microadditives and minerals);

- balancing additives (meets the needs of animals and birds for a certain trace element, vitamin, protein, etc.);

- complete feed (can be considered as a replacement for natural food).

Types of compound feeds according to the form of products:

- loose (fine, medium and coarse grind);

- granular (dense lumps of a round, elongated shape);

- briquetted (dense rectangular or square tiles).

It is optimal to establish the production of granular products due to the high demand in the consumer market.

Sales market:

- intermediary companies;

- farms;

- nurseries;

- zoos;

- nature reserves;

- private farms.

The advantage of selling feed is regular wholesale purchases by various public and private companies, as well as retail sales to individuals keeping cattle and poultry.

Organizing a feed production business

Let's consider the organization of this type of activity from the perspective of technology, raw materials and required equipment.

Raw materials

More than one hundred different types of raw materials are used in feed production. This is due to both the quality and nutritional value of the feed mixture and the type of animal, bird or fish. The main raw materials for the preparation of feed are:

- hay, straw, cake;

- grain raw materials (barley, oats, corn, beans, etc.);

- flour (herbal, fish, meat and bone);

- starch and syrup raw materials (hydrol, molasses);

- mineral raw materials (salt, chalk)

- chemical raw materials (microelements, urea, vitamins, antibiotics);

A separate group includes protein and vitamin supplements and premixes, which are used in micro quantities to enrich food products.

Technology

Feed production technology varies depending on the required final product and the composition of raw materials. Thus, for the production of feed mixture for weaned piglets and poultry, a necessary step will be the peeling of barley, while for many other species the use of this grain is not required.

The greatest demand on the market is granulated feed, the main stages of production of which are:

- grinding;

- dosing;

- mixing;

- granulation;

- cooling;

- packaging

Primary raw materials (hay and straw) undergo a two-stage grinding process into pieces of 30-40 mm and into particles of 5-10 mm (depending on the recipe). Grain components are also crushed in a crusher, weighed on electronic scales and fed into a dispenser. At the dosing stage, additives enter production. Dosing must be accurate, since the quality of the product depends on it. Next, the components enter the mixer. Here they are processed into a homogeneous mass. At this stage, the preparation of bulk feed is completed, so if there are orders for bulk feed, part of the product can be manually removed and sent for packaging.

After the mixing stage, the resulting mass is sent via a screw or belt-scraper conveyor (depending on the composition of the line) to a hopper-agitator, which ensures accumulation and uniform supply of the mass to the press granulator. At the granulation stage, regular lumps of the desired diameter and size are formed. Next, the product is cooled by the counter-wind flow of the cooling column fan and fed to the sieving table, where the final product is separated from the substandard bulk. At the final stage of production, the granules enter the packaging unit via a conveyor. Products are packaged in bags of 10-50 kg.

Necessary equipment

It is optimal to start launching a feed production business by purchasing a small line or mini-plant. Let's consider two options for kits for starting a business.

The optimal solution for small businesses would be the acquisition of LPGK and KR-02.

To start a business, you need to prepare a workshop and warehouse space.

Feasibility study of business

Capital expenditures

- Equipment: 1.15 million

- Delivery, installation: 0.25 million.

- Inventory: 0.5 million

- Preparatory work: 0.3 million

- Business registration and other expenses: 0.1 million.

Total capital costs for starting a feed production business will be: 2,300,000 rubles.

Calculation of revenue at 50% load

* Profitability of activities was determined based on the expert opinion of the author of the article.

Farms and private farms are now actively developing. People raise cattle and poultry for sale, as well as for personal consumption. At the moment, many are wondering about proper and high-quality nutrition, and are concerned about the living conditions of animals on farms and farms.

The length and quality of their life, weight gain, and overall health depend on the feed consumed by livestock and poultry. That is why farms, nurseries and owners of private farms are concerned about finding a supplier of high-quality and inexpensive combined feed for the animals they care for.

Production and supply of combined nutrient mixtures for poultry and livestock – a very promising business with low investments and high prospects. The information provided in this article will help you start a business selling feed to private farms and private farms using minimal costs.

Types of combined feed

In order to talk about doing business on combined feeds, you should understand some concepts and become familiar with the main types of products that farmers buy and use when working with poultry and cattle.

Compound feed is a balanced, nutritious mixture for farm animals and birds, enriched with vitamins and minerals for rapid weight gain, good health and overall high-quality nutrition for pets.

There are various recipes for making combined mixtures. The main one can be considered a composition of several varieties of grains, flour of different coarseness, chalk and salt. Nutrients and vitamins are also added. The cost of a kilogram of the finished product will vary depending on the number of ingredients added and the vitamin content of the mixture.

The recipe for each subspecies of farm animals and birds will be different - the composition of feed for horses is unlikely to be suitable for feeding piglets or domestic ducks. Fish also need combined feeds.

The feed is available in different forms - loose, granular and briquette. The loose form is distinguished by coarse grinding and looks like loose powder. Granular - in the form of lumps (elongated and round). Briquettes look like dense tiles of rectangular or square shape.

The greatest demand is for food in granular form. Powdered feed is the cheapest, but it is difficult to sell because it requires additional preparation before feeding the animals.

Composite feed markets

The business of selling compound feed is effective because farms purchase nutritional mixtures for animals and birds on an ongoing basis. That is, in one day of operation of a farm with no more than five animals, about 12 kilograms of feed are used. Based on these data, we can say that the systematic purchase of combined mixtures is the key to the successful functioning of the farm by extending the life and quality of life of all animals on it.

Most farmers currently refuse the services of foreign suppliers of nutritional mixtures for animals in favor of domestic ones. The high price and speed of delivery tips the scales in favor of Russian suppliers of combined feed.

Target markets for the manufacturer of combination feed mixtures for livestock and poultry:

- Agricultural farms (the most desirable option for the supplier, since farms most often specialize in a certain type of animal and have a high number of livestock);

- Nature reserves and nurseries (feed mixtures with an unusual recipe may be required, which can bring more profit or hassle to the entrepreneur);

- Private farms:

- Zoos (a large number of different animals require large supplies of a varied composition of the combined feed).

This article will provide the necessary information for organizing your own mini-factory for the production of nutritional mixtures for farm animals and poultry without the use of hired labor and at minimal cost.

Production process of combined mixtures and main costs

You need to ask yourself the question of purchasing the necessary equipment for making nutritional mixtures. The acquisition and creation of a production line for grinding, packaging and granulating ingredients will cost an average of 1,200,000 rubles. Here you should also add the costs of renting production premises, as well as premises for a warehouse.

You need to ask yourself the question of purchasing the necessary equipment for making nutritional mixtures. The acquisition and creation of a production line for grinding, packaging and granulating ingredients will cost an average of 1,200,000 rubles. Here you should also add the costs of renting production premises, as well as premises for a warehouse.

You will also need a good supply of raw materials for the manufacture of products, which will require searching and selecting a reliable supplier of ingredients for nutritious feed mixtures. So, according to minimal estimates, the organization of the work process will amount to 2,200,000 rubles (provided that not the most powerful equipment is used).

Production and warehouse premises must have a temperature of at least +5°C, have sufficient area (minimum 60 square meters) and have ceilings with a height of four meters.

The production process of combined feed can be divided into several stages:

- Grinding of raw materials (hay, straw, grain, chalk, salt, flour, etc.)

- Dividing into portions (if an order has been received for crumbly feed, then it is actually ready);

- Making granules;

- Product cooling;

- Packaging of the combined mixture in bags from one to ten kilograms.

It is very important to follow the dosage when preparing the feed mixture and add ingredients exactly according to the recipe - the quality of the final product depends on this.

Combined feeds can be packed into bags manually, in the absence of equipment for packaging nutritional mixtures.

You should also take care in advance about the certification of manufactured products. Combined nutritional mixtures that are not approved by veterinary standards and have not been tested for compliance with GOST will cause mistrust on the part of a potential buyer. Therefore, when producing the first batch of combined feed, you must immediately contact the certification authorities to undergo all necessary testing for quality compliance.

Organization of sales channels

When implementing a business idea for selling compound feed, you may encounter high competition. You should look for customers based on the location of production. If the warehouse is located within the city, then you can focus on the speed of delivery of feed mixtures.

The main task is to find one or two regular buyers of combined nutritional mixtures and work for their benefit for a long time.

Attract customers with attractive prices, moderate discounts and fast deliveries. Analyze the competitive environment and identify a distinctive feature that will make your products stand out from the products of other manufacturers.

Organize meetings with potential buyers, send trial samples of products, and don’t skimp on introductory booklets and attractive packaging. You can search for clients using the Internet (for example, create your online store) and by phone - the main thing is to “hook” the seller and arrange a meeting or sale.

Unsold food can be sold on the market - to do this, it is enough to negotiate with several sellers.

Profit from the business of selling feed

Experienced entrepreneurs believe that with an eight-hour working day with a daily productivity of half a ton per hour of high-quality combined nutrient mixture, the business pays off in 12-14 months. That is, in order to break even in at least a year, you need to produce more than 90 tons of feed per month and sell it without any leftovers. Profit should be increased due to the volume of products sold. Feed mixtures should be supplied in bulk, and for particularly large quantities the price should be slightly reduced in order to interest the client and encourage him to further cooperate.

Analyzing the reviews and recommendations of people who have already implemented the idea of a business selling feed for poultry and animals, we can say that with good marketing and the presence of 2-3 regular customers, you can make great money. Many manufacturers of combined food for animals become owners of livestock farms themselves - this is convenient for testing products. By gradually improving the quality of products, you can conquer nearby markets and become a monopolist in the production of combined nutritional mixtures in your region.

Read more:

Home business - dumplings

Compound feed (combined feed) refers to feed mixtures in various combinations. These mixtures are used to feed farm animals and poultry, providing them with complete nutrition, rich in protein, vitamins and microelements.

They are made according to different recipes (each type of animal has its own), but any compound feed usually includes grain raw materials, grass, pine, fish or meat and bone meal, salt, chalk and other useful additives - products from the microbiological and chemical industries . The nutritional value of compound feed depends on the qualitative ratio of the components that make up it.

Despite the fact that the situation with the agricultural sector in our country is still quite difficult, breeding poultry, large and small livestock plays an important role in this segment. Here, mainly small farms predominate, which have their own narrow specialization, which does not allow them to independently provide all their needs, including animal feed. Therefore, producing combination feeds for livestock and poultry can be a great idea for your own business, especially if you have the necessary knowledge and experience in this field. Traditionally, agricultural workers prefer imported feed. However, recently, due to the high cost of the latter, farms have been purchasing more domestically produced feed, some of which are no longer inferior in quality to their foreign counterparts.

There are three different types of compound feeds, depending on their nutritional value: concentrate feeds, complete feeds and various protein and mineral supplements. The exact composition of each type of feed is determined by the recommendations of veterinarians and the latest research data in the field of the influence of various substances on the taste of the product. Compound feed, which constitutes a complete diet for poultry or animals, must contain the entire range of essential nutrients in strictly maintained proportions, since it is used as a replacement for natural food.

Concentrates are called compound feeds that are used to increase the essential nutrients (minerals, microadditives, protein) of natural feed. Such feeds act as the main component of the diet of animals and birds, but are not the only ones in it. Unlike the previous two types of feed, combined protein-vitamin supplements are produced not by third-party companies, but by agricultural partnerships themselves based on their own raw materials. Compound feeds are also distinguished by the form of the product, which can be loose (various grinding: fine, medium and coarse), in the form of granules (dense lumps of a round, elongated shape) and in the form of briquettes (rectangular or square tiles). Also, feed can be classified depending on the type of animal (for example, whether it is intended for slaughter, breeding, sale), its age and breed.

The key issue that new feed producing companies will have to resolve is related to the quality of their products. Farm animals and birds must receive a balanced diet, on which their health, quality of products, and life expectancy directly depend. Another problem has to do with pricing. Obviously, the retail price of good food will not be low. However, since farms in our country are going through hard times, they have to choose animal feed based, first of all, on the criterion of affordability.

Domestic producers of compound feed sell their products through intermediary companies (wholesalers), as well as directly to end customers - farms, nurseries, zoos, private farms and nature reserves. Ideally, of course, it would be desirable to agree on regular wholesale purchases with public and private companies. Thus, you can ensure stable sales of your products. But most likely at first your main clients will be private farms and individual farmers who keep livestock and poultry.

So, what do you need to produce animal feed? You should start not with searching for equipment, premises, or sales channels, but with developing recipes. The fact is that there are over a hundred types of different raw materials that are used for the production of animal feed. The exact composition of each type of feed, the ingredients and their quantities depend on several factors, including the nutritional value and quality of the feed mixture produced and for whom it is intended. It is impossible to list them all, but we can highlight the basic components that are included in most mixtures. First of all, these are grain raw materials (oats, barley, beans, corn, less often wheat, etc.), hay, straw, cake is often used, flour to increase nutritional value (grass, fish, meat and bone), starch and syrup raw materials (hydrol, molasses), chemical raw materials (mainly vitamins, microelements, urea, antibiotics) and mineral additives (chalk, salt). In addition, various protein-vitamin complexes and premixes are added to combined feeds. These components are present in the mixture in very small quantities and are used rather to enrich the main food product.

Various technologies are used to produce combined feeds. The choice of a specific technology directly depends on the composition and type of the final product. Different raw materials require different processing. The structure of feed production involves the implementation of main and auxiliary operations. The main ones include those actions that are directly related to the transformation of raw materials into feed. And auxiliary operations are not directly related to feed production. The latter include transportation, reception, placement and storage of raw materials, storage and release of finished products, processing of waste from the main production, etc. The process of preparing combined feeds can be divided into several main stages: reception, weighing and storage of raw materials, purification of raw materials from foreign impurities, peeling oats and barley, moisture-thermal processing of grain, crushing grain and other components, drying and grinding mineral raw materials, preparing a mixture of microadditives with filler, introducing liquid additives into mixed feed, dosing components according to the recipe, mixing components, granulating or briquetting mixtures, accounting and distribution of compound feed.

First, the primary raw materials (straw and hay) undergo a two-phase grinding process into pieces of 30-40 mm and into particles of 5-10 mm. The exact particle size obtained during this operation is determined by the formulation. Grain components, if necessary, are cleaned, crushed in a crusher, weighed on electronic scales and sent to the dispenser. On the dispenser, all components, including additional additives, are measured in the required proportions, and then thoroughly mixed. The dosing stage is the most important in the production of compound feed, since the quality of the finished product directly depends on how accurately all components are measured. In the mixer, all ingredients are mixed into a homogeneous mass. If we are talking about the production of compound feed in bulk form, then their preparation ends here. The finished feed mixtures are weighed and packed into bags, which are then sent for storage. If it is intended to produce feed of other types (for example, in the form of granules), then the mixed semi-finished mixture is sent for subsequent processing. When mixing, the mass is fed into the agitator hopper using a screw or belt conveyor. The semi-finished product is collected in the hopper until sufficient mass has accumulated, after which it is sent to the granulator press. Using this equipment, neat lumps of the required diameter and size are formed from the loose mixture. Then the feed is cooled by a fan and goes to the sieving table. The formed granules are selected from the total mass and transferred along a conveyor to packaging. Compound feed in loose form or in the form of granules is packaged in bags of 10-50 kg.

Recently, technology such as extrusion has also been used for the production of combined feeds. It includes three main processes: temperature treatment of the feed, carried out under pressure; mechanochemical deformation of the product, “explosion” of the product using shock discharge. The advantages of this method of producing compound feeds lie, first of all, in improving the taste of feed products as a result of the formation of various aromatic substances in the feedstock. And this, in turn, leads to a significant increase in enzyme activity during the digestion of animal feed. In addition, extrusion neutralizes a number of toxins. During extrusion, raw materials are processed under pressure up to 40 atmospheres and temperatures up to 200 degrees Celsius. As a result, an expanded, porous product is obtained from the extruder in the form of a rope (strand) with a diameter of 20-30 mm with a volumetric mass of 100-120 grams per cubic meter. dm and humidity 7-9%. Heat treatment not only changes the structure of the raw material, but also causes profound destructive changes in nutrients. For example, proteins undergo denaturation, and starch is broken down into dextrins and sugars. As a result of all these changes, an extrudate with a pleasant bready taste and aroma is obtained. According to its characteristics, high-quality extruded feed should have a degree of starch dextrization of at least 55%, an explosion coefficient of at least 4, and a degree of crystallization (swelling) of at least 35%. However, since lines for the production of extruded feed are very expensive, most young manufacturing companies use small lines or mini-plants, which can be used to produce loose or granulated feed at a low cost. Fortunately, the choice of such equipment on the Russian market is quite large. Its cost depends on performance.

For example, a simple line for the production of mixed feed in bulk and in granules with a diameter of no more than 10 mm with a productivity of 1000 kg of product per hour will cost 1.2-1.5 million rubles. Three people are enough to operate it. A more powerful line with a capacity of 3000 kg of products per hour costs about 2.5-3 million rubles. It will require four operators to operate it. In addition to both lines, you will need a chopper for herbal raw materials. The simplest model, which will allow you to chop hay and straw in an embankment, will cost about 20 thousand rubles.

Equipment for chopping straw in rolls is significantly more expensive - approximately 350 thousand rubles. In addition to equipment, you will need premises for a production workshop and warehouses. Add to this the cost of purchasing the first batch of raw materials.

The minimum cost for organizing the production of mixed feed will be from 2.5 million rubles (subject to the use of low-power equipment). These costs can be recouped, as equipment suppliers say, within a year and a half.

LilySysoeva

- portal of business plans and manuals

Agriculture is an extremely promising area for business if you approach it wisely. Every year the number of both private farms and state agricultural organizations that require large quantities of feed and other consumables is steadily increasing.

Based on this, the production of compound feed can become a very profitable business.

In this article we will look at a typical project for such a case, which will require the required minimum costs. If you find a more or less reliable sales market, then you will definitely not suffer from a lack of orders.

What it is?

Combined feed (compound feed) is a product that is intended specifically for feeding domestic animals or poultry. The basis is grain or grass meal, meat and bone or fish meal is used as protein additives, and specialized additives are introduced into its composition to provide the livestock with all the necessary microelements and vitamins.

Why is this type of food needed?

If you are far from agriculture, then you are guaranteed to have this question. Isn't it easier to feed animals or poultry with their natural food? No, in the conditions of modern intensification of agriculture, such an approach is unreasonably expensive. In addition, the same cattle (cattle) are now kept in large agricultural complexes.

Most often, animals do not even graze, and therefore strictly balanced feed is needed to maintain their productivity and physical condition in order. They can only be provided by well-established feed production.

Therefore, farmers are very interested in high-quality products of this kind. They know very well that it is not worth saving on them, as this can be fraught with a complete loss of profit. In a word, if you establish production in any agricultural region, you will have a real gold mine at your complete disposal!

What range of mixed feeds is there?

Oddly enough, the range of special-purpose feeds is huge; there are separate recipes not only for different types of animals, but also for sex and age groups. In addition, there are separate foods for pregnant, old and young animals, for different food groups (downy or meat rabbits, for example).

Division of feed by nutritional value

- Concentrated feed containing the maximum amount of nutrients and energy.

- Balancing additives designed to cover the needs of animals for certain microelements or vitamins.

- Complete combined feeds for daily nutrition. Particularly common in cattle breeding and pig farming.

In what forms is feed produced?

- Loose varieties of medium and coarse grinding are especially common.

- Granular fractions, popular in poultry and pig farming.

- Briquetted feed, recently used in cattle breeding and horse breeding.

Determining the sales market

We have already mentioned that it is extremely important to decide in advance on the market for your products. After all, the size of your revenue depends on this.

The worst option is to sell feed to intermediary companies. It is bad because such organizations are not inclined to set normal purchasing prices, since their owners practice a common type of domestic “business”, when intermediaries buy feed from producers for pennies, selling it at exorbitant prices to consumers.

Their direct sale to state-owned agricultural enterprises, as well as private farmers, looks much more promising. If you live within a large city, producing feed for sale to zoos can be a very tempting and profitable idea. The disadvantage is widespread nepotism and the exclusion of outside producers from such a profitable market.

In any case, strive to find wholesale sales opportunities. However, in rural areas you can always sell surplus products to households.

What raw materials will you need?

In general, in the manufacture of the most “advanced” feeds of this type, more than a hundred varieties of raw materials are often used. However, the average feed production consumes much fewer ingredients. This is especially true when making food for cattle.

Therefore, let’s look at the main types of raw materials that you cannot do without in any case:

- hay, as well as different varieties of cake and meal (if there is no hay, high-quality straw may be suitable);

- grain of high quality and not infected with fungal diseases;

- meat, fish or meat and bone meal;

- molasses or starch production waste;

- table salt and chalk;

- vitamins, microelements and feed antibiotics;

- in some cases the use of separate protein premixes is required.

Feed production technology

The production process itself largely depends on what kind of feedstock you intend to use. For example, barley must undergo a process of flattening and cleaning, but wheat does not need to be crushed. Accordingly, for feed based on it, pressing machines are not needed. Since today at least 90% of the demand is for granulated feed, let’s consider the technology for their production.

The following stages are distinguished:

- The raw materials are thoroughly crushed.

- Everything is brought to a homogeneous consistency.

- The mixture is thoroughly mixed.

- The mechanism forms individual granules.

- They are dried and cooled.

- After this, the finished feed is packaged.

Depending on the recipe, hay or straw is crushed into pieces ranging from 10 to 40 mm in length. The grain is crushed in a special crusher. All elements that are added to feed mixtures are added at the stage of mixing these two components. The composition is sent to the mixer, in which it is brought to a completely homogeneous state.

Note that the stage of feeding into the agitator container is extremely important, due to which the raw materials are evenly fed into the press granulator. If you neglect the installation of such equipment, then the granules may not be very uniform in weight and appearance.

Equipment

Of course, at first you should limit yourself to purchasing only basic equipment, since the agricultural business is a rather risky industry. We will look at two options for the simplest production line.

Firstly, we advise you to turn your attention to the LPKG-1 line. It can produce not only granular (8 mm) feed, but also loose feed.

Firstly, we advise you to turn your attention to the LPKG-1 line. It can produce not only granular (8 mm) feed, but also loose feed.

Only three workers are required to operate the entire installation. Another advantage is that the feed production technology in this case does not require the hiring of highly qualified personnel.

In an hour, the line produces at least a ton of feed with a power of the entire installation of 43 kW. It costs approximately 1.2 million rubles. We highly recommend purchasing a “KR-02” straw and hay chopping machine in conjunction with the installation.

It costs about 20 thousand rubles. Total 1,220,000 rubles. Agree that such a business plan for the production of compound feed is quite realistic and does not require any enormous costs for equipment.

The "LPKG-3" line is very similar to it. The main difference is that it is designed for larger businesses. It can also produce loose and granular feed. At least four people are required to maintain the production cycle. As in the previous case, it is not necessary to look for qualified labor.

In an hour, the line produces three tons of finished feed with a power of 76 kW. Its cost is approximately 2,300,000 rubles. The manufacturer recommends purchasing this equipment in conjunction with the IRR-1M straw roll chopper. Its cost is about 400 thousand rubles. Total 2,700,000 rubles.

Capital investments in small production

- The equipment will require approximately 1.3 million rubles.

- At least 400 thousand should be set aside for its installation and delivery.

- Raw materials for the first time will require approximately 500 thousand rubles.

- It will take at least 400,000 to prepare the workshops.

- It sometimes takes at least a million rubles to complete documentation and other bureaucratic red tape.

Thus, everything will require about 3.5 million rubles. It is impossible to calculate the costs of wages and social benefits, since it greatly depends on your region. Keep in mind that the amount of social benefits is about 34% of the wage fund.