Handmade soap making technology. Handmade soap production as a business. Raw materials for soap production

From a technological point of view, soap production is not particularly difficult. Many people start doing it at home as a hobby or extra income. But a professional approach to the issue makes soap making a fairly profitable business.

To do this, you need three basic resources:

- premises (for a small production and packaging/bottling line with a capacity of up to 80 kg/h, 60-85 sq.m. will be sufficient);

- soap production equipment and process flow chart;

- quality raw materials.

In addition, you will need personnel trained to operate the equipment, storage space for raw materials and finished products (warehouse), as well as distribution channels.

Premises requirements

The soap workshop should be located in a sufficiently high room– at least 3 meters. It is advisable to finish the ceilings, floors and walls with moisture-resistant coatings. It is desirable that the floor has a slope to allow condensate to drain into the sewer network. For comfortable operation of equipment and personnel, heating, high-quality natural and additional artificial lighting will be required.

From engineering conditions, the soap production line will require connection to an electrical network with a power of at least 60 kW/h and a voltage of 380 V.

Since water is included in the soap making process, care must be taken to supply a continuous cold water supply and further soften it. It is necessary to remove manganese and iron particles dissolved in it as much as possible from the water: if their quantity is small - using filters, in the case of a fairly high concentration - with multi-stage water treatment systems.

Usually, no additional ventilation is required in the soap workshop, since soap production technology does not involve the release of large amounts of harmful substances and heat. An exception may be cases when an increased amount of different fragrances is used.

Raw material base for soap making

The required set of starting components, as well as the soap production technology, depends on the type of raw material:

- full production cycle – cooking directly from fats;

- production of a finished product based on a semi-finished product - soap base.

The basis for making soap from scratch is vegetable and animal fats. Animal fats can be of natural origin (lamb, pork, beef, fish, prefabricated compounds, products of their processing) or synthetic.

In the production of liquid soap, mainly liquid vegetable oils are used.

In addition to the fats themselves, lards are also used in their natural form - hydrogenated (hydrogenated) liquid fat components. As a result of such processing, they turn from liquid to solid form, and the content of fatty acids in the raw material increases.

Synthetic fatty acids for soap production are obtained from the oxidation of petroleum paraffin.

The basic soap formula also includes esters: palm oleate and palm stearate.

In addition to the main one, you will also need auxiliary raw materials for soap production:

- alkalis (for saponification of fats). Use caustic soda and caustic soda;

- dyes;

- bleaches to give the soap an even light tone;

- fragrances - usually for perfumed solid soap the concentration of odors is significantly higher than for liquid soap, since fragrances are designed to mask the characteristic fatty odor. If industrial production is used, toilet soap can be prepared with complex multicomponent fragrances;

- antioxidant stabilizers to prevent oxidation of the finished soap;

- additives to give soap special properties (disinfecting, reducing skin degreasing, therapeutic and prophylactic, abrasive).

In a simplified version, the raw material is a ready-made soap base, which is then melted with the addition of various auxiliary ingredients.

The recipe for a particular variety may include a different set of components depending on the desired properties, but the most natural ingredients are especially popular among buyers.

If you plan to produce laundry soap, the technology may include processing components with a strong unpleasant greasy odor. In this case, it is advisable to provide filters on exhaust ventilation systems.

Do you like finishing facades with stone, then you will be interested. After all, artificial stones are in no way inferior to natural ones, and in many properties they are superior to them.

If you like clean streets and want to make the world a cleaner place, then you can make your dream come true with waste recycling lines. you can find answers to all your questions about it.

Want to learn more about key making technology? Then on the page you can read more about it.

Soap making technology

Regardless of the type of soap (laundry, cosmetic or liquid), its preparation is based on the same chemical and physical processes.

To bring the semi-finished product to marketable condition you will need:

- mixer;

- mill;

- molds for making soap or molding machine;

- cooler;

- automatic machine for cutting bars;

- belt conveyor.

During the production process, the base for making soap is crushed and melted, all the necessary additives are added to it, after which the soap mass is cooled and cut or molded. To do this, it may be advisable to purchase a ready-made production line: at initially comparable costs, it makes it possible to use automated control, and the time for installing the line is noticeably reduced.

Toilet or baby soap is usually prepared from the base. To make laundry and liquid soap, no additional processing is required, so it is made from primary (fat) raw materials.

The process of making soap from fats includes two stages:

The process of making soap from fats includes two stages:

- chemical (actual cooking)

- and physical (subsequent processing, bringing to marketable condition and packaging).

The second stage will require the same set of equipment as when processing the base. Making soap from soap base is less expensive, but the high cost of raw materials can negatively impact overall profitability.

At the first stage, special mixing boilers are additionally required, in which the saponification reaction will occur.

Direct or indirect soap making methods are used. In the first case (direct method), a 40-60% solution of fatty acid salts (soap glue) is prepared from fat and alkali. The resulting mass is poured onto baking sheets and cooled.

The indirect method involves an additional operation of salting out (treating with table salt) the hot soap mass. As a result, two fractions are formed: concentrated soap (sound soap) with a fatty acid concentration of at least 60% and soap lye - the remains of the electrolyte (salt), glycerin, and alkalis that have not reacted.

Using an indirect method, laundry soap with enhanced cleaning properties is obtained. The same method is used to obtain purified soap base, which is subsequently used in the production of solid grade toilet soap and baby soap.

Liquid soap is most often made using the direct method with prolonged cooking of the composition to obtain a uniform emulsion. If you plan to produce liquid soap, no molding equipment will be required; it will be replaced by a bottling line for the finished product.

Full-fledged soap production on an industrial scale pays for itself, according to experts, within 6 months with the correct selection of equipment and organization of the production process.

Soap making video

Not every person likes to earn money while sitting in an office or working in a factory. Many people prefer to start a business based on their hobbies. One popular small business movement is making and selling handmade soaps. Why is this business relevant - handmade soap? First of all, soap making is a relatively new form of art, and even more so, making money. The idea of making homemade handmade soap arose 8-10 years ago, and the idea of selling it on a fairly large scale appeared 3-4 years ago. That is, we can conclude that in most cities the niche has not yet been occupied.

Soap made at home from natural ingredients attracts many buyers because it can cleanse, treat the skin and have a beneficial effect on the general condition of the external integument. Often it does not cause allergies (depending on the components used), so it is suitable for sensitive skin. Unusual, beautiful handmade soap attracts the attention of buyers. Such a product is in demand if production and sales are properly organized.

Registration of home soap making as a business

Before officially registering a business, it is necessary to find a suitable premises and purchase the necessary primary materials and create a small business. To produce and sell soap, you can register or.

Premises of 40 sq. m. will be quite enough. If you want to save on rent, choose a suburban option. The space should be divided into two parts of different sizes. The larger one will serve directly as a production site, and the smaller one will serve as a warehouse for raw materials and finished products.

Registration of a soap-making business takes place at the tax office and does not take much time.

Handmade soap production technology

Before you understand the production technology, you need to purchase all the necessary tools, products and components for soap. It’s better if you have a certain amount saved up for this, which will allow you to choose everything you need at once.

Required materials and equipment

Soap base

A product consisting of fatty acids and glycerol. It has a transparent or white color and is usually sold by weight. There is also a liquid soap base (for liquid soap and shampoos). If you plan to produce products in this direction, then a liquid base is also necessary.

Carrier oils

To prevent soap from drying out the skin and causing irritation, various solid and liquid oils are added to it. Basic oils are usually the following: olive, coconut, jojoba. There are other base oils - the choice should depend on the type of soap being made.

Ethers

Essential oils are added to soap for aroma and various effects. The choice here is wide: from aromatic ylang-ylang to simple tea tree. Each of the oils is antiseptic, which can be an excellent addition to soap against rashes on the face. Esters make soap fragrant.

Dyes

Special dyes will help make the soap bright, varied and achieve originality. The variety of dyes is great - it’s worth purchasing as many colors as possible so as not to limit yourself in creativity. Choose natural dyes: low cost is not as important as quality and recognition among consumers.

Fillers

Soft gommage components and scrubbing additives (apricot kernels, ground coffee, raspberry seeds, fiber from fruits and berries, synthetic abrasives) can also serve as fillers. You can also add dried flowers, gelatin and other additives to soap.

Fragrances

Essential oils provide a wonderful aroma, but you can’t do without additional fragrances. The assortment of the modern handicraft market allows you to purchase flavors with all kinds of odors.

Forms

Several sets of molds of various modifications will be enough to produce a product of various shapes and variations.

Basic forms:

- classic (rectangular);

- gift (paired shapes, hearts, holiday options for Easter, New Year and others);

- children's (dolphins, cartoon characters).

Scales

To accurately measure the weight of the finished piece, you need a good scale. Do not buy mechanical ones under any circumstances - they have too much error for such production.

Capacities

Pans without enamel (preferably stainless steel), molds for a water bath, as well as knives and graters for the soap base, pipettes, mixing spatulas, measuring cups and spoons - all this will be needed in the process.

Product promotion

After making trial versions of several types of soap, you can post photos of the product on your personal blog. Due to the development of information technology, advertising on the Internet is the most effective.

To sell throughout the country, you can create a group on any social network. Selling using an Instagram account is effective. Attractive photographs play a big role here. It's not a sin if you process them well.

If opportunities allow, creating your own website for promotion will not be superfluous. On it you can create an online store system and accept orders.

A very good service from soap makers is making custom soap. This could be handmade gift soap, soap with certain additives, etc.

Don't forget to tell your relatives and friends about your business. The so-called “word of mouth” can bring you additional income and new regular customers.

Possible difficulties in this business

Difficulties include low demand for products, force majeure in the production process when producing in large quantities and, as a result, waste of raw materials and time, lack of funds for the purchase of all necessary ingredients.

Sometimes problems may arise with SES without a special certificate. To obtain quality certificates for products, batches must be checked in the laboratory, and a certain amount must be paid to obtain the document.

To avoid any difficulties in organizing this business, you need to think through all expenses, have initial capital, correctly select all the necessary materials and tools, and study the market in your area.

To prepare solid soap, take 2 kg of caustic soda, dissolve it in 8 liters of water, bring the solution to 25°C and pour it into melted and cooled to 50°C lard (the lard must be unsalted and take 12 kg 800 g of it for the specified amount of water and soda). The resulting liquid mixture is thoroughly stirred until the entire mass becomes completely homogeneous, after which it is poured into wooden boxes, well wrapped in felt, and placed in a warm, dry place. After 4-5 days, the mass hardens and the soap is ready.

If you want to have a more foamy soap, then add another 400 g of purified potash to the specified amount of water or take 2 kg less lard and add the same amount of coconut oil. To prepare liquid soap, dissolve the same amount of unrefined caustic potassium in 2 kg of water, bring the solution to 25°C and mix thoroughly with 8 kg of unsalted lard, previously melted and cooled to 50°C. in the future proceed as indicated above.

PRODUCTION of medical soaps

1. Vaseline-lanolin soap. 3.5 kg of petroleum jelly and 1.5 kg of lanolin are added to 95 kg of molten soap mass. Used as a skin softener.

2. Camphor soap. Take 10 kg of the best tallow soap, 400 g of rosemary oil and 400 g of camphor. When the soap has melted and needs to be placed in molds, add finely crushed camphor mixed with 25 g or more of bitter almond oil, also rosemary oil, and stir well.

3. Tar soap consists of 12-16 ordinary soap and 1-2 birch tar.

4. Vaseline-tar soap. This soap consists of 9.5 kg of coconut oil, 5 kg of lard, 8.25 kg of lye at 38 ° B, 3.2 kg of wood tar, 1 kg of yellow petroleum jelly, 83 kg of water, 70 g of rosemary and 50 g of lavender oil. Soap is prepared at 45° C.

5. Sulfur-tar soap (5%). 1 kg of sulfur color is mixed with 4 kg of heated birch tar and added to 95 kg of soap mass.

b. Carbolic soap. Ordinary white soap is mixed with 2-3% carbolic acid.

7. Sublimate soap. When preparing mercuric soap, it is necessary to use good soap with an excess of free fat, since all mercuric soaps containing free alkalis become covered with black spots after a few days of production. Sublimate is added to soap up to 0.1%.

8. Menthol soap (5%). 95 kg of soap powder and 5 kg of menthol are mixed and pressed. Used for washing hair for neuralgia.

9. Thymol soap (3%). 3 kg of thymol is mixed with 97 kg of soap powder and

ireSSuYu. Thymol soap has a pleasant odor and is used as an antiseptic.

10. Formalin soap (5%). To 95 kg of soap powder add 5 kg of formaldehyde (containing 40% formaldehyde). Formalin should not be mixed with hot soap, since if the latter is alkaline, formic acid can easily form.

PRODUCTION OF SHAVING SOAPS

1. Hot shaving soap. This soap is prepared from 12 kg of fat, 4 kg of lard and 250 g of rosin. All these materials are boiled down to a solid core. After cooking, carefully separate the solid mass from the liquor and place it in a special vessel. Then, in another kettle, 3 kg of coconut oil is boiled with 2 kg of 30° potash lye. After the saponification process is completed, increase the heat and add, stirring thoroughly, the previously prepared sound soap. If the mass should not be too thick, then add another 2 kg of water and boil until the sample taken hardens on the glass. When the soap is ready, the mass is poured into molds and 50 g of lavender oil is added to fragrance the soap.

2. Cold shaving soap. Take 14 kg of lard, 2 kg of bleached palm oil, 4 kg of coconut oil, 8 kg of soda lye at 30° B.; for aromatization, add 100 g of lavender and 80 g of tympanic oil.

3. Remelted shaving soap. 4 kg of lard and 2.5 kg of coconut oil are melted in a sand or water bath; 2.75 kg of potassium liquor at 42° are added to the melted fat, stirring continuously. When about half the lye is added, the mass begins to thicken, but when all the lye is added, it is so thick that it is impossible to stir.

The mixture is left at a temperature of 60-70 ° C for several hours alone. The hardened mass is ground in a marble or porcelain mortar, gradually adding 9 g of bitter almond oil, previously dissolved in 100 g of alcohol.

4. Liquid shaving soap.

a) Mix 60 g of olein with 125 g of hot water and add to the resulting liquid, with strong stirring, 50 g of soda lye and, finally, 120 g of white soap. The entire mixture is diluted with 75 cm3 of hot water, and 25 cm3 is added. alcohol and strained

b) Mix 1 kg of white soap, 100 g of almond oil. 500 g of alcohol, 500 g of rose water, 10 g of amber and 10 g of benzoin tincture.

5. Shaving soap paste. Take 90 g of spermaceti, 90 g of sweet almond oil, 100 g of potassium soap and bitter almond oil for fragrance.

6. Shaving soap powder. Stir 400 g of soap powder, 50 g of borax and 25 g of almond bran.

PRODUCTION OF ORDINARY SOAP

1. Making soap using an artisanal method. Take wood ash or ash obtained from burning weeds and sift it through a sieve, then scatter it, moisten and mix until a uniformly moistened mass of ash is obtained. After this, it is collected in a pile, in which a depression is formed on top. The latter is filled with lime, which is quenched by the presence of moisture. Lime should be taken in half the weight of the ash taken. When the lime disintegrates into a fine powder, it is covered with ash. Then pour water over it and leave for 24 hours, after which the lye is drained. This is the first lye, the most concentrated. It is placed in a special vessel, and then water is poured over the ash again, it is drained and a weaker lye is obtained. When this lye is ready, the stronger one is poured into the boiler and heated to a boil.

Next, add the appropriate amount of various fatty waste to the lye and boil, adding weaker lye, until the sample taken on a glass plate hardens into a transparent sticky mass. This method produces liquid potash soap, usually called soap glue. To turn the soft mass into hard, dense soap, add table salt to the soap glue. In this case, the so-called soap core is released, which is a solid soda soap.

After adding table salt, the resulting core soap is scooped out, as well as the lye, after which the soap is placed again in the cauldron, boiled again with thicker lye, salted again, scooped out and placed in boxes lined with linen; when the excess lye adhering to the soap collects drop by drop on the bottom of the box, turn the box over, take out the soap, cut it into pieces and air dry.

To make soap, it is better, of course, not to take ash and lime, but directly caustic soda.

2. Preparation of simple soap - solid and liquid, a) To prepare solid soap, take 2 kg of caustic soda, dissolve in 8 kg of water, bring the solution to 25 ° C and pour it into melted and cooled to 50 ° C lard (the lard should be unsalted and take 12 kg 800 g for the specified amount of water and soda). The resulting liquid mixture is thoroughly stirred until the entire mass becomes completely homogeneous, after which it is poured into wooden boxes, well wrapped in felt, and placed in a warm, dry place. After 4-5 days, the mass hardens and the soap is ready. If you want to have a more foamy soap, then add another 500 g of purified potash to the specified amount of water or take 2 kg less lard and add the same amount of coconut oil instead.

PRODUCTION of toilet soaps

i. Hot method. As the main mass for toilet soaps, you can take lard soap prepared with soda lye, or prepare it separately using pork fat combined with coconut oil.

The coconut oil must be of the highest quality, and the lard must be extremely fresh and well-refined.

Fat is purified as follows: fresh fat is washed several times in cold water, cut into pieces and placed in a bag, which is suspended in a cauldron of water and boiled. When the water boils and the lard dissolves, it is lightly squeezed out, with most of the fiber remaining in the bag along with the debris. The bag is removed, and into the mixture of lard and water, for each kilogram of lard, add 4-5 g of table salt and 1-2 g of powdered alum, with the liquid boiling strongly and constantly stirring. After some time, the boiling is stopped and the fat is allowed to float to the surface. The resulting scale is carefully removed, filtered through a linen into a clean vat and allowed to harden. In this way, cooked fat can be stored unchanged in a cool place for a very long time.

To obtain a good toilet soap, take 5-20 g of coconut oil for every 100 g of fat. The latter is added not only to reduce the cost, but also to “fill” it with more water.

The soap making itself is done in the usual way, you just need to make sure that the resulting soap is neutral, that is, that it does not contain an excess of alkalis. For this purpose, it is salted several times and then boiled again. After the last salting, boiling is continued until the sample taken with a glass rod on the plate turns out to be completely satisfactory, that is, when the mass is squeezed between the fingers, solid plates are obtained that should not break.

In order to have completely pure soap, it is stirred with a pole, the foam is removed and poured into molds until it is transparent. The soap mass remaining at the bottom of the boiler will be less transparent and clean, and therefore it must be allowed to harden separately.

2. Cold method. The preparation of toilet soaps in the cold way, by stirring, has many advantages, which mainly boil down to the fact that here coloring and perfumery are carried out simultaneously, constituting, as it were, one operation, after which all that remains is to cut and stamp the hardened soap mass.

To prepare soap using the cold method, take coconut oil, previously cleared of random dirt, and saponify it with strong soda lye at low temperature and constant stirring. In order for the resulting soap to be neutral, it is necessary to make several preliminary tests and accurately determine the quantitative ratio of fat and alkali. On average, you have to take caustic soda in solid pieces about 15% by weight of the fat part.

When the saponification process reaches the point where the contents of the cauldron turn into a homogeneous and difficult to stir mass, then coloring and perfume substances are added to it, which, due to prolonged stirring, are evenly distributed throughout the mass.

3. Melting. The preparation of toilet soaps by melting is carried out as follows: ordinary sound soap is cut into pieces and thrown into a cauldron inserted into another cauldron with boiling water (water bath). So much water must be added to the soap so that the sample taken has a good consistency, after which the soap is poured into molds and mixed with coloring and perfume substances. The amount of added water poured for remelting depends on the properties of the soap: for hard greasy soap you need to take more water than when using other varieties that already contain a lot of water. Generally, enough water is poured so that when it cools, you get a solid soap that foams strongly in the water.

If the soap taken for re-melting is heavily contaminated, then it must be melted with a large amount of water (50-60%), and then salted and boiled.

4. Planing. The preparation of toilet soap by planing is carried out as follows: core soap is turned into shavings using a special machine, collected in a wooden trough, mixed with coloring and odorous substances and then turned into a homogeneous mass using a kneading machine. The machine consists of a horizontal cylindrical drum, on the circumference of which there are 4-8 knives. Above the drum, which is driven into rotation, there is an inclined plane on which layers of soap are placed for planing. The soap is pressed by its own weight onto the drum, the knives of which continuously cut shavings from the soap layer. The knives are installed at a very significant slope and therefore can cut chips as thick as writing paper.

Here are a few recipes for Italian soaps, made in different ways:

5. Almond soap. To prepare it, take 4 kg of white soap, scrape it into small shavings and add a little milk. The mass is poured into the cauldron, placed on moderate heat and stirred until it thickens and begins to stretch. After cooling, add artificial bitter-almond oil and pour the soap into a flat wooden box with linen at the bottom. The soap is allowed to cool and harden, and then it is cut into pieces of the required shape.

In factories, almond soap is prepared from good strong lye with twice the weight of lard, fat, coconut or palm oil, which must be boiled until the sample taken out, placed on a cold smooth plate, quickly hardens.

6. Pink soap. To prepare this soap, take: 64 coconut oil, 40 tallow soap, 30 water and heat this mixture for 2-3 hours, knead and add a little eosin for tint. Then remove from heat and add artificial rose oil. Soap is poured into molds.

7= Violet soap= To prepare this soap, which gives softness to the skin, take 100 white core soap, 10 orris root, 10 dew incense. The soap is mixed with water, dyed purple and scented with violet essence. Then add as much starch as is necessary to impart hardness to the soap, after which the soap is placed in molds.

8. Lemon soap. Mix, with gentle heating, 1 white fatty soap and 1 starch, paint it yellow and scent it with lemon essence. The resulting mass is molded into special molds in the shape of a lemon and tinted on top in a yellow-lemon color, dipped in yellow paint with the addition of wax.

E. English round soap. To prepare this soap, you need to cut 200 good white soap into small pieces and then grind it in a heated porcelain mortar, adding 1 camphor to the mass. 100 starch is added to the resulting batter, painted in different delicate tones and perfumed. Flat-round pieces are formed from this mass.

10. English shaving soap is prepared as follows: 100 ounces of white soap are scraped into small shavings and dissolved in water until the consistency of liquid jelly. Then add 10 talc and 10 powdered alum, paint it creamy and perfume it with musk and orange oil. This soap is cast in a cylindrical shape.

11. Egg soap. The egg yolk is boiled until the water has evaporated so much that no oil oozes out of the yellow mass when squeezed with your fingers. The latter is squeezed out, filtered and turned into soap with the help of potassium. Then mix the yolk with a sixteenth part of this soap, add 1 starch and fragrant oil per 30 yolks and, when it all thickens properly, put it in molds.

12. Glycerin soap. 13 lard and 12 coconut oil are melted in a cauldron and filtered through a thin cloth; a mixture of 12 lye at 39.5° B. and 8 alcohol at 95° is poured into the strained fats. The mass is stirred, then 3 glycerin is poured in and finally the so-called honeycomb is added, consisting of 8 sugar and 5 hot water. When a sample taken on a knife shows that the soap is ready, pour it into molds. Color and scent can be added as desired.

13. Soap cologne. 50 kg basic soap, 60 g lavender oil, 35 g rosemary and 30 g bergamot oil, 70 g lemon oil. For coloring, take 1 g of chlorophyll dissolved in the listed oils.

14. Benzoin soap. 50 kg basic soap, 40 g Peruvian balsam, 1 g

physyl root, 15 and helioironine, 5 and benzoin aqueous. For painting, use brown diamond (aniline) paint.

15. Soap for children. 10 kg basic soap, 200 g white petroleum jelly, 200 g rice flour, 30 g geranium oil, 20 g terpineol. White color.

16. Coloring toilet aches. Soap can be dyed in two different ways: a) Aqueous solutions of basic and acidic dyes are poured into the hot soap mass, with constant stirring. Fat-soluble dyes that are mixed with oil are also suitable for this coloring method. All dyes should not be exposed to alum.

b) Dry soap is cut into small pieces (chips) and processed on a kneading machine together with basic and acidic dyes dissolved in water or ground with oil. This method allows the use of insoluble resinous colored varnishes. This is how marble soaps are made.

The dyes used to tint toilet soaps can be very different. The main conditions that they must satisfy are: to be strong enough, mix well with soap and not have a harmful effect on the skin. Such paints can be divided into two groups: soluble and insoluble. The former deserve preference over the latter simply because they do not leave behind an insoluble powdery residue; In addition, soluble paints are distributed in soap more easily and evenly than insoluble paints.

Red color. For transparent soaps: alkanine, magenta, eosin. For opaque ones - cinnabar, red lead.

Yellow. For clear soaps: turmeric extract and picric acid. For opaque ones - chrome yellow paint.

Orange color is made up of a mixture of red and yellow dyes.

Green color. For transparent soap: green aniline or a mixture of indico-carmine and picric acid. For opaque ones - chrome green paint.

The violet color is composed of methyl violet or a mixture of red dye and indigo carmine.

Brown color - from light or dark brown aniline dye or burnt

GYAUYAPYA

"

Insoluble paints are used in the form of a fine powder, which is sprinkled on the chips entering the planer drawer. Then a new layer of shavings is applied to the sprinkled shavings, which are again sprinkled with paint, etc. When all the soap is prepared in this way, the shavings are stirred and passed through a kneading machine to obtain a uniformly colored mass.

17. Perfuming toilet soaps. Along with a first-class, completely neutral soap base (core soap), perfumery plays a particularly important role in the manufacture of toilet soaps. The fact is that the fragrance should not only be pleasant, but should also retain its smell for a long time and even, if possible, improve when the soap lies and dries.

When starting to perfume, you need to strictly distinguish which types of soap you want to perfume, and accordingly select the necessary odorous substances. Toilet soaps are divided, as we have seen, into those that are made 1) hot

method, 2) cold method, 3) by hand, 4) by chugging.

Therefore, when perfuming, the first question is at what temperature the soap should be perfumed. Then, secondly, what is the effect of alkalis on the odorous substances used. And finally, thirdly, are these odorous substances well preserved in alkalis? The entire art of skillful perfumery of toilet soaps is based on these three main questions.

Toilet soaps made by hot method or by melting are, for the most part, cheap varieties. You can’t spend a lot on perfumeing them so that these soaps don’t cost too much. Therefore, to perfume such types of soaps, you can choose only cheap odorous substances, but which nevertheless have a possibly stronger odor, since it is with these types of soaps that it is often necessary to kill some unwanted extraneous odor. For this purpose, they mainly use mirban oil, safrole, citronella oil, and artificial bitter almond oil.

For the second category of cold process toilet soaps, that is, for good grades of coconut soaps, higher quality odorants can be used, and the choice among them seems to be more varied. Although coconut soaps, which also include almond soaps, have recently been pushed into the background by planed soaps, good and pure coconut soaps are bought very willingly, especially in areas where the water is very chalky, and therefore planed soaps do not lather well. Coconut soaps can be perfectly perfumed thanks to the numerous natural and artificial fragrances available. You can also significantly improve the quality of these soaps by adding lanolin to them. Even soaps with the addition of Japanese wax are very popular, since they look exactly like planed soaps. They should just not be left in the mold for a long time, otherwise they become too hard and very difficult to press.

Of the odorous substances, we can highly recommend aniseed aldehyde, which has a very delicate smell, bornyl acetate, which is remarkably good in coconut soaps; citronella oil, which is especially good for honey soaps. Then, a good effect can be achieved with coumarin, eugenol and geranyl acetate. You can also recommend nerolin, and especially terpeneol. Cinnamaldehyte is also used with brilliant success. The smell of violet can be achieved with ionone II, with the addition of terpenol, and brilliant results are obtained from the use of artificial nerol oil.

18. Marbling of toilet soaps. It is produced with the aim of giving them the appearance of spotted or veiny marble. To do this, pour liquid soap into a mold to a known height, sprinkle or pour the surface with insoluble resinous varnishes, then pour a new layer of soap, perform the same operation, etc., until the mold is filled. A wooden spatula is dipped into the soap mass and stirred, moving it parallel to the walls of the mold. If they want to get wavy marbling, then move the spatula along curves or spiral lines. Various paints are used for variegated marbling.

b) To prepare liquid soap, dissolve the same amount of unrefined caustic potassium in 2 kg of water, bring the solution to 25 ° C and thoroughly mix with 8 kg of unsalted lard, previously melted and cooled to 50 ° C. Then proceed as indicated above.

There are many benefits to having a home business. There is a huge amount of information about this. To open your own business you need to have suitable premises. It is also worth considering that the initial investment should not be high. An excellent example of a small home business is the production of useful and beautiful soap, which has a special uniqueness, on its own. All the funds that you initially invest in this business will pay for themselves after six months. The profitability of such production is 50%. But such results can be achieved only through a properly organized business, established sales and the presence of creative potential in the person who makes the soap.

In Russia there is very little supply for the sale of homemade soap. People are more accustomed to using soap that is produced in factories for their needs. Handmade soap in the markets costs about 120 rubles, and soap delivered from abroad costs up to 210 rubles. For example, in Moscow such a market has already reached a huge amount - $1 million. It grows annually by 22%. This means that there is demand for these products now, and will only increase in the future. Therefore, opening your own soap factory will justify itself. There is a buyer for beautiful, healthy and unique soap.

Production technology

The process of manufacturing any product necessarily begins with the need to purchase material. What can’t you make fragrant soap without? Of course, without soap base. The main investment will be made for the purchase of this material. 1 ton of soap base costs 160 thousand rubles. Don't think that you won't need that much raw material. If initially this is indeed the case, then it is worth remembering that everything is calculated in proportions. From 1 ton of soap base, as much as 600 kilograms of finished soap are obtained.

A variety of fragrances, as well as essential oils, without which it is impossible to make good soap, must be purchased in bulk. 5 kg of such materials have a price of 60 thousand rubles.

Various additives in the form of acids, vitamins, fats will also cost you 60 thousand rubles.

You will spend all this raw material no less than after 4 months of constant work. The soap base will only last you for 2 months.

This cost calculation perfectly coordinates novice entrepreneurs and shows how best to plan their production.

Methods for making soap at home

There are several methods for making soap at home. You can initially use the most popular and proven one.

- It is necessary to melt the soap base. This is easy to do using ordinary household appliances. For example, a microwave oven. A water bath also works great. 250 grams of soap base can be melted in a microwave oven at 400 W. This will only take 2 minutes. If you need to melt a large amount of raw materials, then simply increase the power and operating time.

- A variety of additives and essential oils must be added to the base heated to a liquid state. To stir thoroughly.

- Pour the resulting mixture into soap molds and wait until it hardens completely.

Important to remember. It is strictly forbidden to boil soap base. That is why it is not recommended to heat it with an open fire. If it is heated for a long time, the constituent component of the base, namely glycerin, may begin to burn. This will cause the base to become dark in color and have an unpleasant odor. Such soap can only be suitable for household needs.

For 200 grams of soap base you need:

- essential oil – 6 – 8 drops;

- oils – 0.5 teaspoon;

- flavorings – 6 – 14 drops;

- liquid dye – 2 – 14 drops;

- igment – 1/3 teaspoon;

- titanium dioxide – 2 – 6 teaspoons;

- cosmetic clay – 2 – 6 teaspoons;

- ground oats – 4 – 8 teaspoons;

- additives, for example honey – 2 – 6 teaspoons

A good master should know about 25 recipes that can be used to make soap. The result should always be a beautiful-looking soap with beneficial properties and a pleasant aroma.

- Now the soap can be packaged. This is the last step of the whole process. Handcrafted soap is usually purchased not for daily use, but as an original gift. This is always worth remembering. Soap prepared according to different recipes must have separately designed packaging.

Thus, customers will always be able to recognize it, and it will not get lost on store shelves. Packaging can be either cardboard or plastic. On it you can write the composition of the soap, its original name. If you produce 500 kg of soap per month, the packaging material will cost you 45 thousand rubles.

How to organize mass production of homemade soap?

To start soap production you will need a room of 45 square meters. meters. In one half of it there should be all the equipment for production, and in the other there should be tables for the soap to harden there. This takes about 3 hours. The room must be equipped with all communications. There are no special requirements for it.

At first, soap making can be done by one person. If sales volumes increase, you need to think about hiring more people. In order to produce and package 500 kg of soap, the work of 5 workers is required. For that. To ensure that the packaging has a unique, beautiful design, you need to use the services of a professional designer. Every holiday should have its own line of designer soap. If you constantly update your product range, then customers will always be interested in purchasing something new.

Soap made from scratch

Organizing sales is no less important work than making soap itself. Sales points are everywhere. These include stores selling cosmetics, gifts, and household goods. You can take part in all kinds of fairs, or offer soap at the market. It wouldn't hurt to create your own online store.

You can sell soap sets during the holidays

If you can produce 500 kg of soap, then the net profit will be 490 thousand rubles monthly. This is the case when the price of one product is about 95 rubles. If you can increase production volumes and sell all goods on time, then your income will only grow.

A soap factory at home is a good idea for a small business without significant financial investments. The profit margin will depend on how many finished products you can produce. There are usually no problems with implementation.

Soap making at home

I would never have thought that soap production, or how to correctly say soap making, at home could be such a profitable business if I had not been convinced by the personal experience of my friends.

The undoubted advantage of this business is that it does not require large financial costs to start it. And the profit from home soap making can cover all production costs in just five to six months. Considering this, it is not surprising that this began to actively develop in Russia during the years.

To open a business producing handmade soap, you will need an initial capital of 500,000 rubles. Business profitability is about 50%.

Handmade soap market

In this article we will look at the market closest to us - the soap market in the Russian Federation. At the moment, there are about a dozen companies in Russia that are exclusively engaged in the creation of handmade soap. We should not confuse these companies with cosmetic companies that produce soap, shampoos and other toiletries. The cost of a bar of soap is about 150-250 rubles. The price depends on the company, on the appearance of the bar of soap and on its contents.

If we take the glorious city of St. Petersburg as an example, where about 20 stores selling soap are now concentrated, then their sales volume is about a million dollars a year! That's right, I was impressed by this figure... not bad for a soap store!? If you believe experts, they say that this market in Russia is covered by less than 50%.

One point should be taken into account in the positioning of handmade soap in Russia and the West. If over the hill people buy such soap for themselves, actually as soap, then from us, as a gift. That’s why Russians are so picky about its appearance... it’s worth taking this feature into account when creating your own business!

Soap production technology

Making soap at home is quite simple. The so-called casting method is used here. First, you need a soap base - the component that makes up 99% of soap. You can easily find suppliers of soap base on the Internet.

This base is placed in a saucepan or a special vessel, and various components are added there: flavors, dyes, etc. Then this whole mixture is brought to a boil. Well, the last stage consists of pouring liquid soap into pre-prepared molds, or cooling in the vessel itself - in one large piece, which is subsequently simply cut into small pieces, usually 100 grams each.

But we remember that we live in Russia, and they buy soap from us as a gift, no matter how wild and funny it may sound. Therefore, the first option would be preferable for us - pouring it into molds. The recipe for making soap, if you follow the rules, should be purchased from foreign manufacturers. But while we are familiar with the concept of a freebie, and while gigabytes of information flow through the wires of our computers, you can find the recipes yourself, for free. Experts advise launching production of at least 20 types of soap. However, their quality must be at the highest level. Remember this!

Organization of manual soap production

Initially, as usual. For the production of soap, a room of 40-50 square meters will do, no more is needed. In addition, these forty squares are divided into two parts, the first is used for preparing the product, and the second as a warehouse. The warehouse is mostly used for preparing soap. The fact is that after the soap liquid is poured into the molds, it needs to cool for three hours, and then, within another 72 hours, the soap finally hardens.

To minimize costs, you can rent a room somewhere outside the city. Actually, you can use any room; there are no special requirements for it. However, this does not mean that soap must be produced in unsanitary conditions! The premises must have everything necessary, including running water, sewerage and, if desired, cosmetic repairs.

The equipment we use is a gas or electric stove, the cost of which will be about 5,000 rubles. For cooking - three vessels with a capacity of 15-20 liters - this is about another 3,000 rubles. And, of course, soap molds. Wooden molds, with various designs and shapes, cost about 5,000 rubles. The set includes 20 molds.

Raw materials for soap production

The lion's share of costs in soap production is the cost of purchasing raw materials. They make up about 70% of all expenses. The raw material is soap base. If you produce 600 kilograms of soap per month, i.e. 6 thousand pieces, then one and a half tons of soap base will be enough for a month and a half. The cost of one ton is about 150,000 rubles.

The costs will also go to all kinds of dyes, flavors and essential oils that we will add to our brew. The cost of the above additives will be about 50,000 rubles. And they will last for 3-4 months. But this is not all the costs. About 30,000 rubles will be spent on purchasing various vitamins, vegetable fats, etc. The supplements purchased for this amount will also be enough for 3-4 months.

Soap packaging

As you already understand, you can’t skimp on packaging either. Our planned production volume is 6,000 pieces of soap, 20 different types. That is, it turns out that twenty different packages should be available. Packaging costs will be about 40,000 rubles per month.

Soap production staff

To produce soap, taking into account all of the above, you will need 5 people. Namely: the cook is the person who will manage the soap production process. He will need one assistant. And three more people will be engaged in the painstaking work of packaging soap. Also, at the very beginning, you will need to contact a designer who will develop a logo and packaging design.

Sales of manufactured soap

And so, you followed our instructions, and now you have 6,000 beautiful bars of soap in your warehouse that need to be sold. This process is no less important than the production itself. It is advisable to have one. Two sales managers whose responsibilities will include selling products to household stores and wholesale customers.

The ideal option would be to create your own store or chain of stores selling handmade soap. But now these are only plans for the future. First of all, you need to produce the first batch and sell it in order to understand whether this business is suitable for you or not.

Instead of a conclusion

So, what have we got? Our expenses, including initial expenses for premises and equipment, will be about 500,000 rubles. Fixed costs, including wages to workers, will amount to 250,000 rubles. Monthly income, with an average price for one piece of soap equal to 90 rubles and with a production volume of 6,000 pieces, will be about 500,00 rubles per month.

At the same time, it is about 50%. At the same time, by increasing production volumes, as well as expanding your soap markets, you can significantly increase your profits several times.

Soap making: secrets of a profitable business step by step

We present to your attention a step-by-step course on opening a home business based on the production of handmade soap.

- The first stage of any business is... The article describes the pros and cons of individual entrepreneurs and LLCs, and in conclusion you will find out what is best for soap production.

- Second phase - .

- The third stage is .

- The fourth stage is ().

- Fifth stage - (,).

- The sixth stage is for business expansion ().

- The seventh stage is (,).

- Eighth stage - .

Soap making business plan

In order to even more clearly demonstrate the pros and cons of this business, as well as to continue to comply with the step-by-step course, we provide a mini business plan with basic calculations and comments... It is worth remembering and understanding that each city will have its own calculations, which are somewhat different for a couple of hundred rubles, and in some cases for thousands, perhaps even tens of thousands of rubles (as regards renting/purchasing premises).

First, let's give a list of what we will have initial costs for:

- Registration of an individual entrepreneur (or LLC, if you immediately want to open a Company)

- Rent/purchase of premises for office and warehouse

- Redecorating. You should not buy or rent a premises that needs serious repairs, or will require it in six months or a year.

- Purchase of necessary equipment and tools for soap production. Unfortunately, there is no way to do without this.

- Initial investment in raw materials for production and ingredients.

- Costs of purchasing/ordering or producing packaging yourself.

- Payment for staff work. Although, this point can be discarded at first, since the first batch (test batch, so to speak) can be made independently, with the help of your husband/wife/children, etc.

Above we have a list of seven points. If we discard the last one, we get six cost items that await us at the initial stage. You can avoid costs for one or more items, for example, provided that you have a premises where you can produce soap and store the finished products.

Below, I will not take this into account in the calculations. Let's take a situation where you have nothing and you have to start, as they say, from scratch.

Expenses

One-time expenses:

- Registration of individual entrepreneur - 800 rub.

- Room 40 sq. m. (purchase) ~ 400,000 rub.

- Cosmetic repairs - RUB 35,000.

- Trade equipment - 15,000 rubles.

- Purchase of equipment - 30,000 rubles. (rounded)

- Scales for weighing liquids - RUB 1,500.

- Oilcloth - 500 rub.

- Steamer - 2,000 rub.

- Stainless steel pans - 10,000 rub.

- Bowl for mixing soap - 300 rub.

- Heat-resistant container with markings and a stainless steel spout - RUB 1,000.

- Pipette - 10 rub.

- Skimmer - 100 rub.

- Measuring spoons - 100 rub.

- Spoon made of plastic or stainless steel - 50 rub.

- Kitchen containers made of plastic - 150 rubles.

- Knife - 50 rub.

- Electronic or laboratory thermometer for food products - 200 rub.

- Oil sprayer - 50 rub.

- Mortar and pestle - 150 rub.

- Spatulas for the kitchen - 100 rub.

- Graters - 250 rub.

- Clamps - 100 rub.

- Whisks - 100 rub.

- Cookie molds - 300 rub.

- Sieve - 100 rub.

- Respirator, goggles and gloves - 1500 rub.

- Funnel/watering can - 50 rub.

- Towels for wrapping soap - 300 rub.

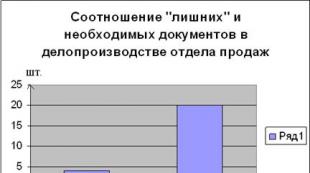

Total one-time costs are: RUB 455,800. (Roughly speaking, it will take 500,000 rubles for everything)

Monthly expenses:

- Packaging (for 6,000 pieces of soap) - 60,000 rubles. (10 rubles per package)

- Salary for staff - 0 rub. At the first stage, you can do all the work yourself, or with the help of your husband/wife, etc. (then it all depends on the number of staff and the average salary in your city).

- Raw materials (based on production of 6,000 bars of soap per month)

- A ton of soap base - 150,000 rubles. (with average volumes - for 1.5 months)

- 5 kg of ingredients - 35,000 rub. (with average volumes - for 3-4 months)

Total, on average, monthly expenses will be: 170,000 rubles. This does not include salary costs! Total costs in the first month will be 500,000 rubles, then monthly costs will be about 170,000 rubles. + salary for employees + utility taxes.

Income

The first batch we produced is 6,000 copies of soap. When selling one bar of soap (100 grams) at a price equal to 100 rubles, we have: 600,000 rubles/month.

Bottom line

As you can see, the business may well pay off in the first month! And subsequently bring up to 350,000-400,000 rubles per month. As you can see, this business is quite profitable and does not require large initial investments or any specific knowledge. Everything is simple and anyone can do it, fortunately the market does not yet have serious competition.